Dynamically-adjustable structural color device based on phase-change material and preparing method thereof

A phase-change material and structural color technology, applied in the field of structural color display, can solve the problems of limited controllability and inability to realize continuously adjustable dynamic structural color, and achieve the effect of simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

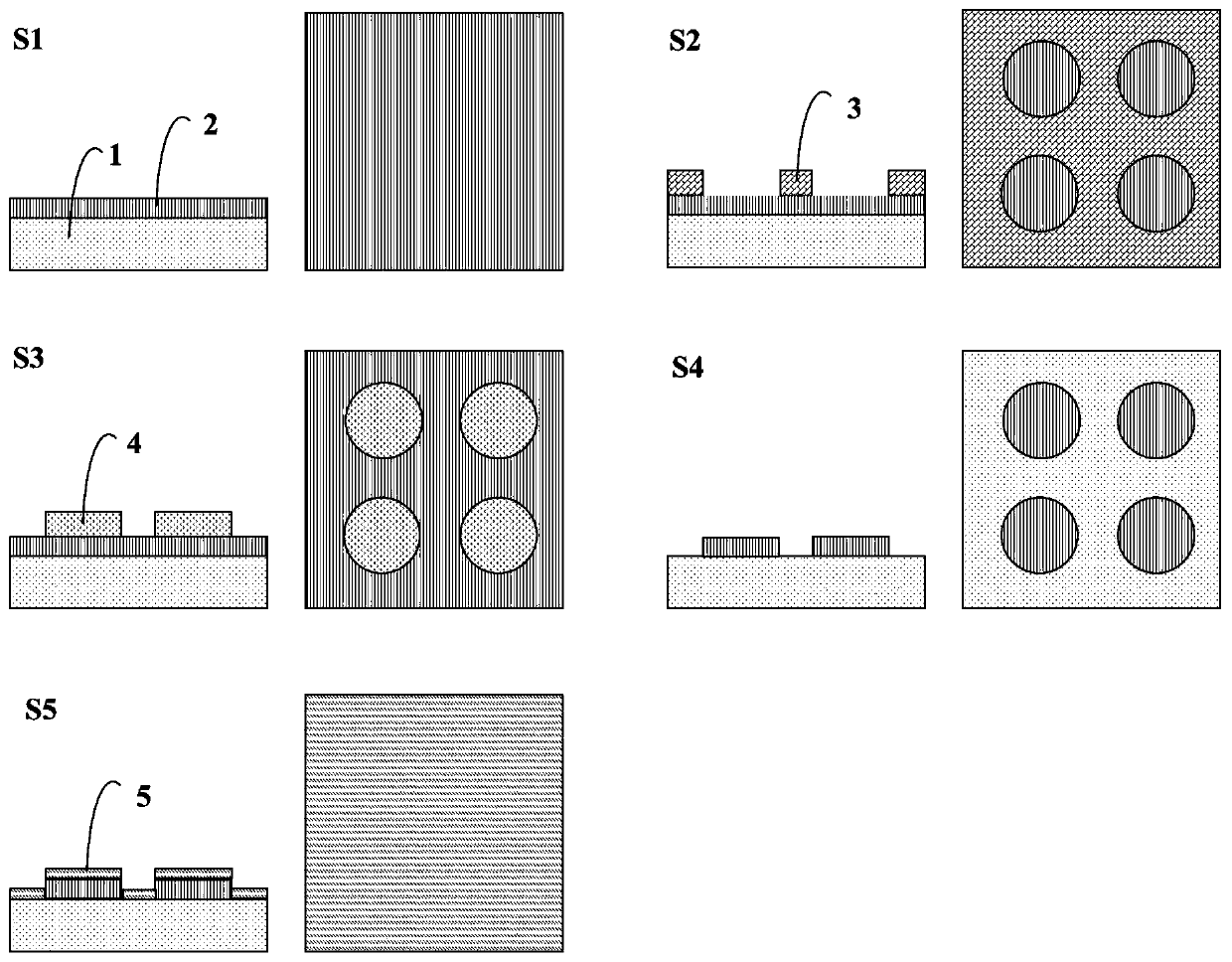

[0040] In order to achieve the above object, the present invention provides a method for preparing a dynamically adjustable structural color device, in figure 1 The schematic diagram of the process flow of the preparation method is shown. The left figure of each step of the process schematic diagram is a vertical section view, and the right figure is a top view. The specific steps are as follows:

[0041] Step S1. Depositing a phase change material film 2 on the substrate material 1, and performing annealing;

[0042] Step S2. Spin-coat photoresist 3 on the phase change material film obtained in step S1, and perform exposure to prepare periodic micro-nano structures;

[0043] Step S3. Depositing a metal thin film 4 on the structure obtained in step S2, and performing stripping to prepare a mask structure;

[0044] Step S4. Etching the periodic structure array obtained in step S3, and removing the remaining metal mask material;

[0045]Step S5. Depositing the metal thin film ...

Embodiment 1

[0067] This embodiment is used to illustrate the preparation method of the dynamically adjustable structural color device of the present invention.

[0068] The following will describe in detail in combination with specific methods.

[0069] according to figure 1 The process flow shown prepares a dynamically tunable structural color device based on phase change materials.

[0070] Step 1. Deposit 90nm VO on the silicon substrate material by magnetron sputtering 2 Films of phase change materials. The target material used in the magnetron sputtering method is a vanadium metal target, using a DC source, the sputtering power is 100W, the pressure is 7mTorr, and the growth temperature is 600°C; after that, a tube furnace is used in Ar / H 2 Annealing was carried out under atmosphere, the annealing temperature was 450°C, the annealing time was 270min, Ar and H 2 The flow rates are 80sccm and 4sccm respectively.

[0071] Step 2. Spin-coat PMMA photoresist on the phase-change mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com