Preparation method of multiply plywood

A kind of plywood, adhesive technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

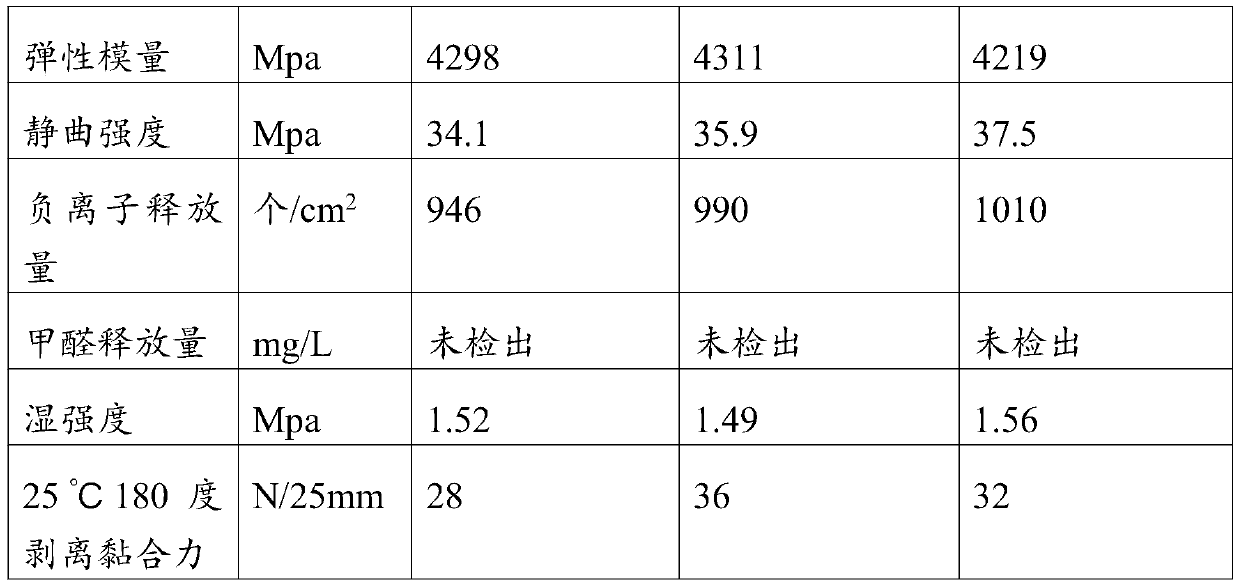

Embodiment 1

[0025] A preparation method for multilayer plywood, comprising the following steps:

[0026] (1) After cutting the wood into sawdust, wood particles or shavings, dry it, soak it in the insect repellent liquid for a period of time, take it out and dry it naturally, then immerse it in the insect repellent liquid again, take it out and dry it to obtain the plywood raw material;

[0027] (2) After laying the plywood raw material flat, spray the adhesive, and spread a layer of sound insulation material, which is a thin sheet compacted with mineral wool, spray the adhesive on the surface, and then spread a layer of plywood raw material to pressurize Prepare and form a first-grade plywood, the thickness of the first-grade plywood is 4mm;

[0028] (3) Wire-cut the first-grade plywood in step (2) on both sides of the first-grade plywood. After the adhesive is laid on the plywood raw materials, it is pressurized to form a secondary plywood. The method of spraying the adhesive is first ...

Embodiment 2

[0037] A preparation method for multilayer plywood, comprising the following steps:

[0038] (1) After cutting the wood into sawdust, wood particles or shavings, dry it, soak it in the insect repellent liquid for a period of time, take it out and dry it naturally, then immerse it in the insect repellent liquid again, take it out and dry it to obtain the plywood raw material;

[0039] (2) After laying the plywood raw material flat, spray the adhesive, and spread a layer of sound insulation material, which is a thin sheet compacted with mineral wool, spray the adhesive on the surface, and then spread a layer of plywood raw material to pressurize Prepare and form a first-grade plywood, the thickness of the first-grade plywood is 12mm;

[0040] (3) Wire-cut the first-grade plywood in step (2) on both sides with a metal wire. After cutting out several arc-shaped grooves, the depth of the groove is 1.5mm, and spray on the upper and lower sides of the first-grade plywood. After the ...

Embodiment 3

[0049] A preparation method for multilayer plywood, comprising the following steps:

[0050] (1) After cutting the wood into sawdust, wood particles or shavings, dry it, soak it in the insect repellent liquid for a period of time, take it out and dry it naturally, then immerse it in the insect repellent liquid again, take it out and dry it to obtain the plywood raw material;

[0051] (2) After laying the plywood raw material flat, spray the adhesive, and spread a layer of sound insulation material, which is a thin sheet compacted with mineral wool, spray the adhesive on the surface, and then spread a layer of plywood raw material to pressurize Prepare and form a first-grade plywood, the thickness of the first-grade plywood is 9mm;

[0052] (3) Carry out wire cutting on both sides of the first-grade plywood in step (2), after cutting out several arc-shaped grooves, the depth of the groove is 1mm, and spray glue on the upper and lower sides of the first-grade plywood After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com