A method for the preparation of ternary cathode materials for lithium-ion batteries by a hydrothermal-assisted co-precipitation strategy

A lithium-ion battery, hydrothermal assisted technology, applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems of decreased electrochemical performance of ternary cathode materials, insufficient stability of material structure, and easy collapse of layered structure. , to achieve the effect of improving electrochemical performance, improving structural stability, and reducing the degree of lithium-nickel mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

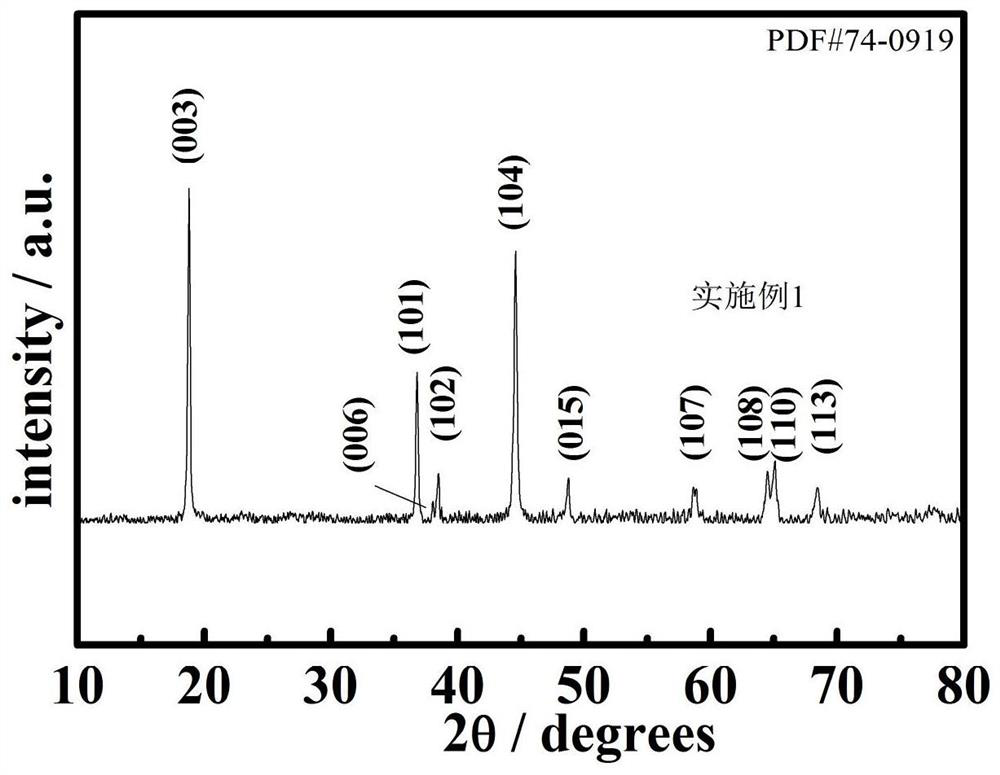

[0029] Example 1. Preparation of lithium ion battery ternary cathode material LiNi by hydrothermal assisted co-precipitation strategy 0.8 co 0.1 mn 0.1 o2

[0030] (1) According to the stoichiometric ratio Ni:Co:Mn=8:1:1, weigh nickel sulfate, cobalt sulfate and manganese sulfate, and add them into deionized water to obtain a total concentration of 2mol L -1 mixed salt solution;

[0031] Mix the above mixed salt solution with 6mol·L -1 NaOH, 3mol L -1 NH 3 ·H 2 O was fed into a continuously stirred 1L reactor in parallel by a peristaltic pump for co-precipitation reaction, the stirring rate was set at 1000rpm, the reaction control pH value was 10.5, the ammonia-salt ratio was 3:4, and the temperature was 60°C, and the reaction was continued for 4h , get Ni 0.8 co 0.1 mn 0.1 (OH) 2 Precursor suspension;

[0032] (2) the prepared Ni 0.8 co 0.1 mn 0.1 (OH) 2 The precursor suspension was placed in a hydrothermal reaction kettle, and crystallized at 180 °C for 40 h;...

Embodiment 2

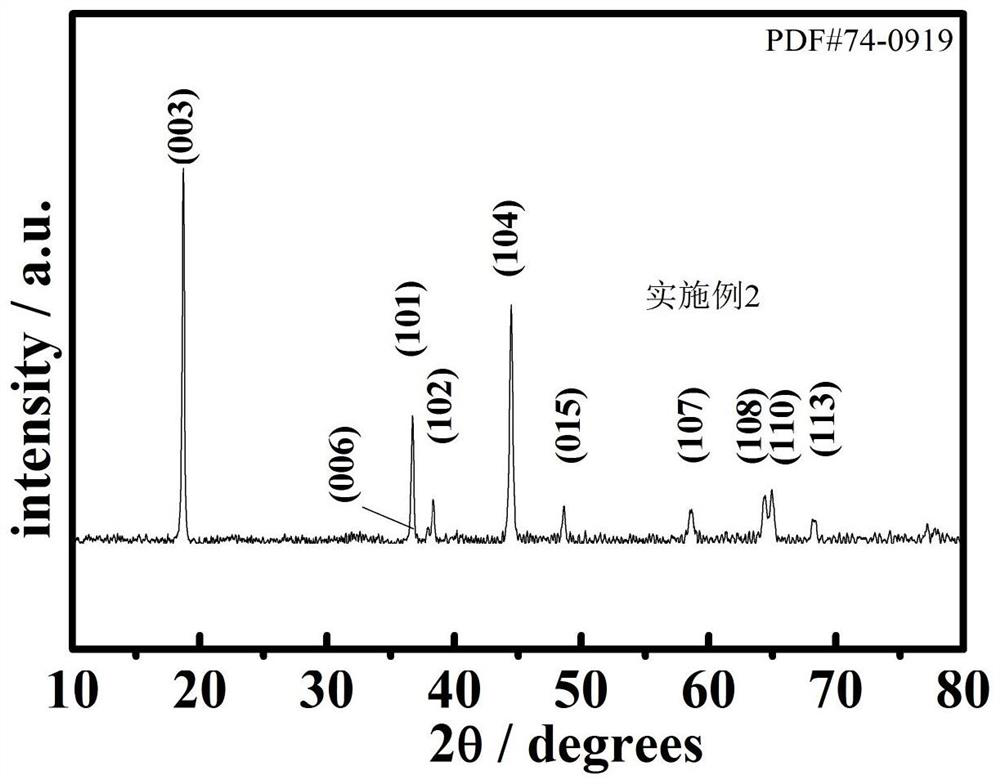

[0035] Example 2. Preparation of lithium ion battery ternary cathode material LiNi by hydrothermal assisted coprecipitation strategy 0.6 co 0.2 mn 0.2 o 2

[0036] (1) According to the stoichiometric ratio Ni:Co:Mn=6:2:2, weigh nickel sulfate, cobalt sulfate and manganese sulfate, add them into deionized water, and obtain a total concentration of 2mol L -1 mixed salt solution;

[0037] Mix the above mixed salt solution with 6mol·L -1 NaOH, 3mol L -1 NH 3 ·H 2 O was fed into a continuously stirred 1L reactor in parallel by a peristaltic pump for co-precipitation reaction, the stirring rate was set at 1000rpm, the reaction control pH value was 10.5, the ammonia-salt ratio was 3:4, and the temperature was 60°C, and the reaction was continued for 4h , get Ni 0.6 co 0.2 mn 0.2 (OH) 2 Precursor suspension;

[0038] (2) the prepared Ni 0.6 co 0.2 mn 0.2 (OH) 2 The precursor suspension was placed in a hydrothermal reaction kettle, and crystallized at 180 °C for 40 h; ...

Embodiment 3

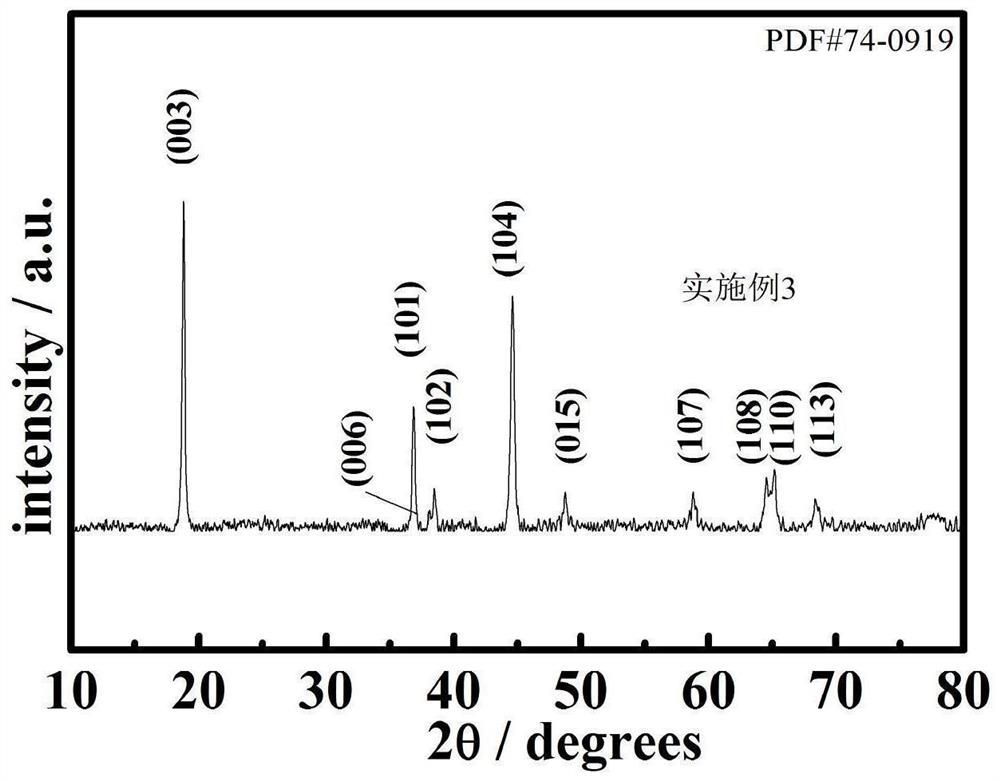

[0041] Example 3. Preparation of lithium-ion battery ternary cathode material LiNi by hydrothermal assisted co-precipitation strategy 0.5 co 0.2 mn 0.3 o 2

[0042] (1) According to the stoichiometric ratio Ni:Co:Mn=5:2:3, weigh nickel sulfate, cobalt sulfate and manganese sulfate, and add them into deionized water to obtain a total concentration of 2mol L -1 mixed salt solution;

[0043] Mix the above mixed salt solution with 6mol·L -1 NaOH, 3mol L -1 NH 3 ·H 2 O was fed into a continuously stirred 1L reactor in parallel by a peristaltic pump for co-precipitation reaction, the stirring rate was set at 1000rpm, the reaction control pH value was 10.5, the ammonia-salt ratio was 3:4, and the temperature was 60°C, and the reaction was continued for 4h , get Ni 0.5 co 0.2 mn 0.3 (OH) 2 Precursor suspension;

[0044] (2) the prepared Ni 0.5 co 0.2 mn 0.3 (OH) 2 The precursor suspension was placed in a hydrothermal reaction kettle, and crystallized at 180 °C for 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com