Preparation method of allyl alkylxanthate collecting agent

A technology of alkyl xanthate and alkyl yellow, applied in the direction of organic chemistry, etc., can solve the problems of high water content in products, increased process cost, difficult to produce propylene xanthate products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A kind of preparation method of alkyl xanthate propylene ester collector, comprises the following steps:

[0039] (1) Sodium alkyl xanthate is dissolved in water, and then synthetic auxiliary agent NF-1 is added to make solution A;

[0040] (2) Add halopropene and synthetic auxiliary agent NF-2 to solution A in sequence, and after the reaction is complete, separate the product phase to obtain alkyl xanthate propylene ester collectors.

[0041] Further, the synthetic auxiliary agent NF-1 is sulfuric acid, hydrochloric acid, nitric acid.

[0042] Further, the synthetic auxiliary agent NF-2 is sodium hydroxide, potassium hydroxide, barium hydroxide, ammonia water, sodium carbonate, sodium bicarbonate.

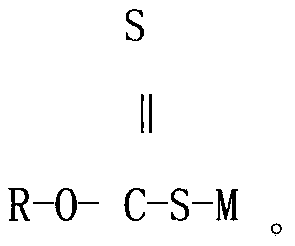

[0043] Further, the structure of the alkyl xanthate is:

[0044]

[0045] Further, the R is ethyl, propyl, isopropyl, butyl, isobutyl, pentyl, isopentyl, hexyl, 2-ethylbutyl, heptyl, octyl, isooctyl, etc. ; The M is potassium, sodium and the like.

[0046] Further, t...

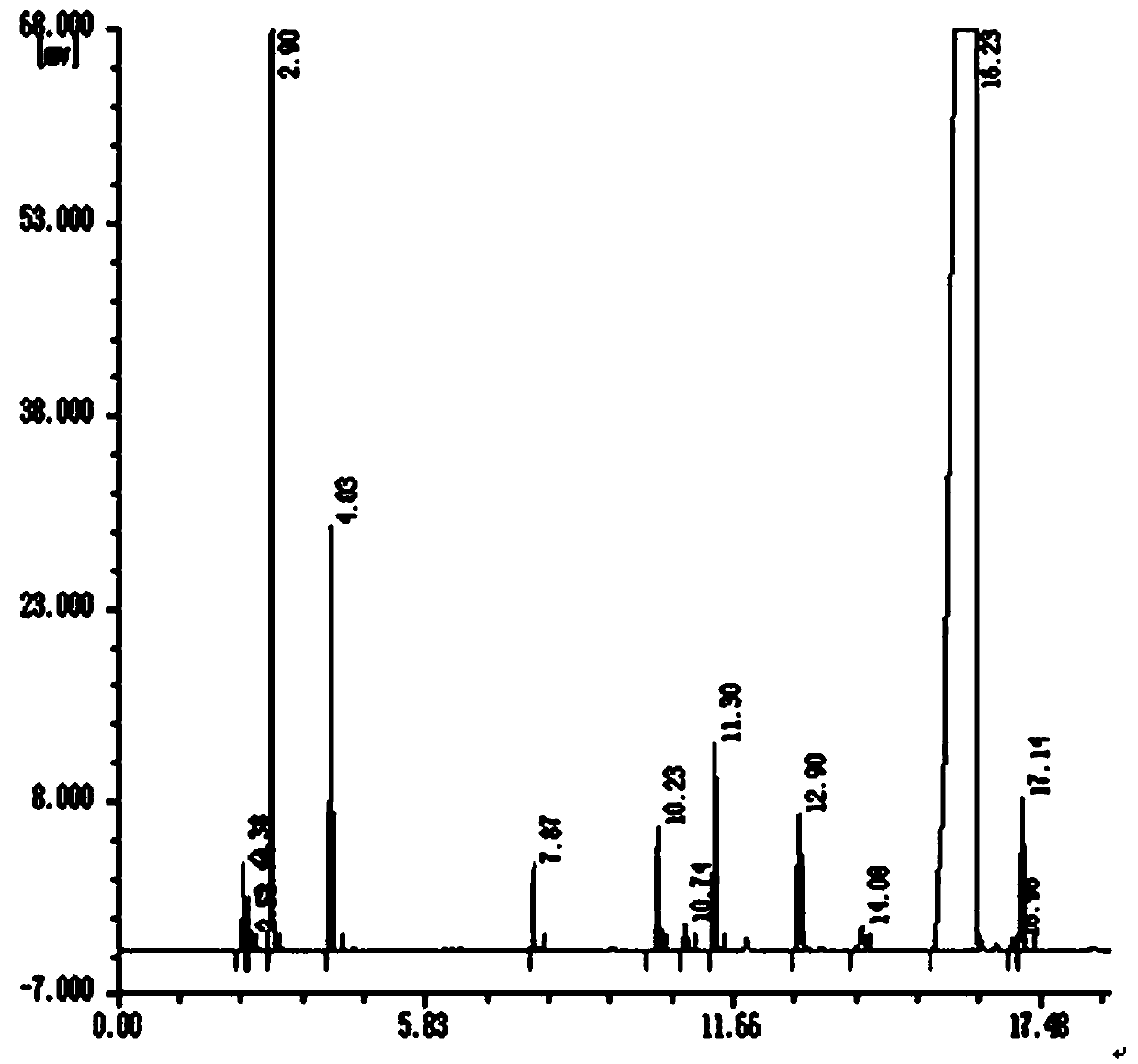

Embodiment 1

[0057] Add 50 grams of sodium isoamyl xanthate (content is 80.19%) in the reactor, add 100ml water, mix and stir for 20min, add dropwise sulfuric acid (content is 50%), adjust the pH value of the solution to 8, then add 17.5 grams Chloropropene (content: 98.31%), then add 2 grams of sodium hydroxide (content: 99%), use a temperature control device, keep the reaction temperature at 30-35°C, react for 2h, after the reaction, static separation, remove the water phase With a small amount of mesophase, 43.1 grams of propylene isopentyl xanthate was obtained, the purity of gas chromatography analysis reached 94.61%, and the product had no pungent smell.

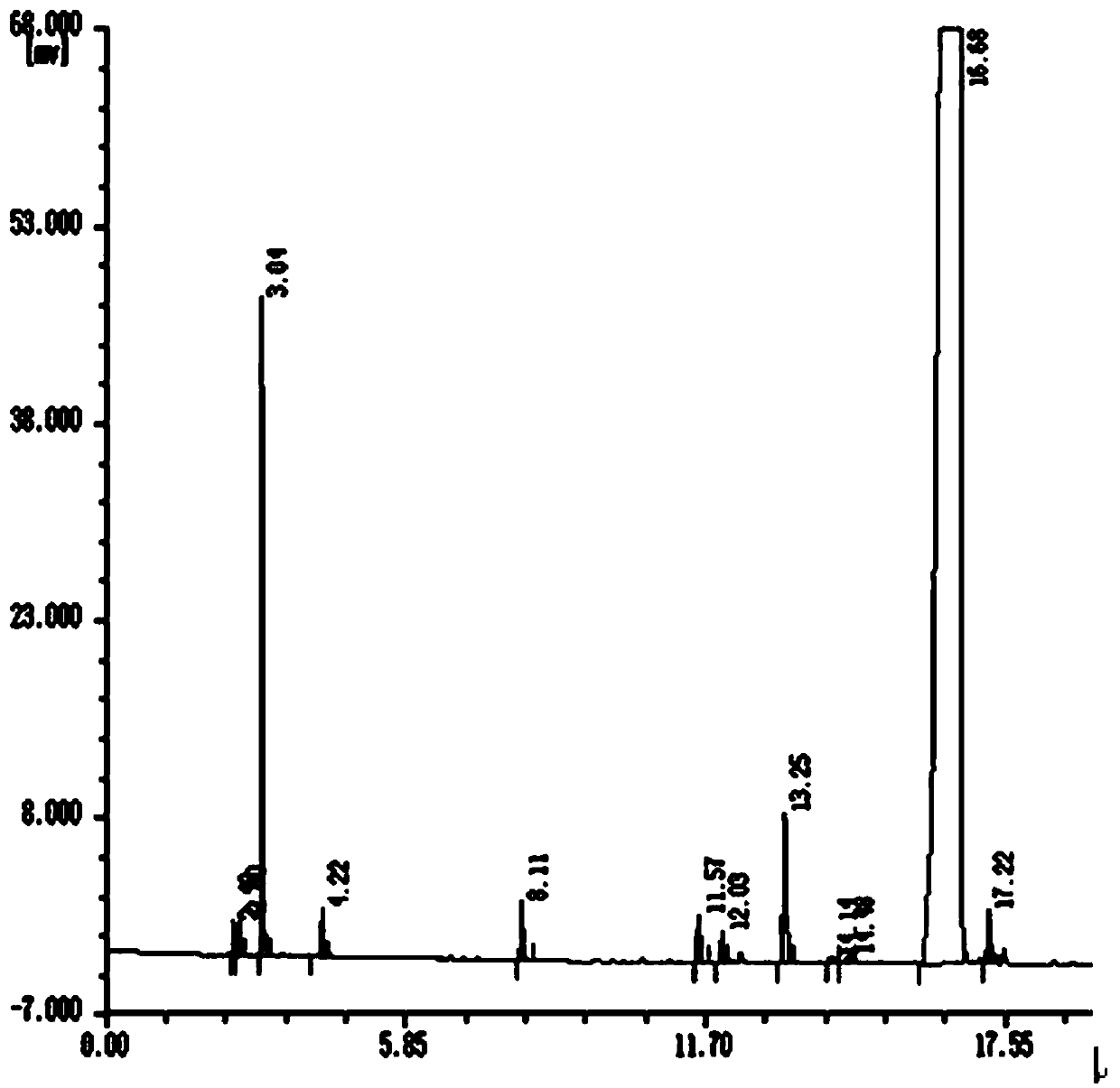

Embodiment 2

[0059] Add 50 grams of sodium isoamyl xanthate (content is 80.19%) in the reactor, add 100ml water, mix and stir for 20min, then add 17.5 grams of allyl chloride (content is 98.31%), utilize temperature control device, keep reaction temperature React at 30-35°C for 2 hours. After the reaction, separate statically, remove the water phase and a small amount of intermediate phase, and obtain 41.4 grams of isopentyl xanthate propylene product. The purity of the gas chromatography analysis reaches 89.09%, and the product has strong irritation. Sexual smell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com