Waterless dyeing disperse dye color paste, preparation method and application thereof

A disperse dye, anhydrous dyeing technology, applied in the field of dyeing and finishing, can solve the problems of easy accumulation, multi-color point, insoluble dispersant, etc., and achieve the effect of small particle size and high fixation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

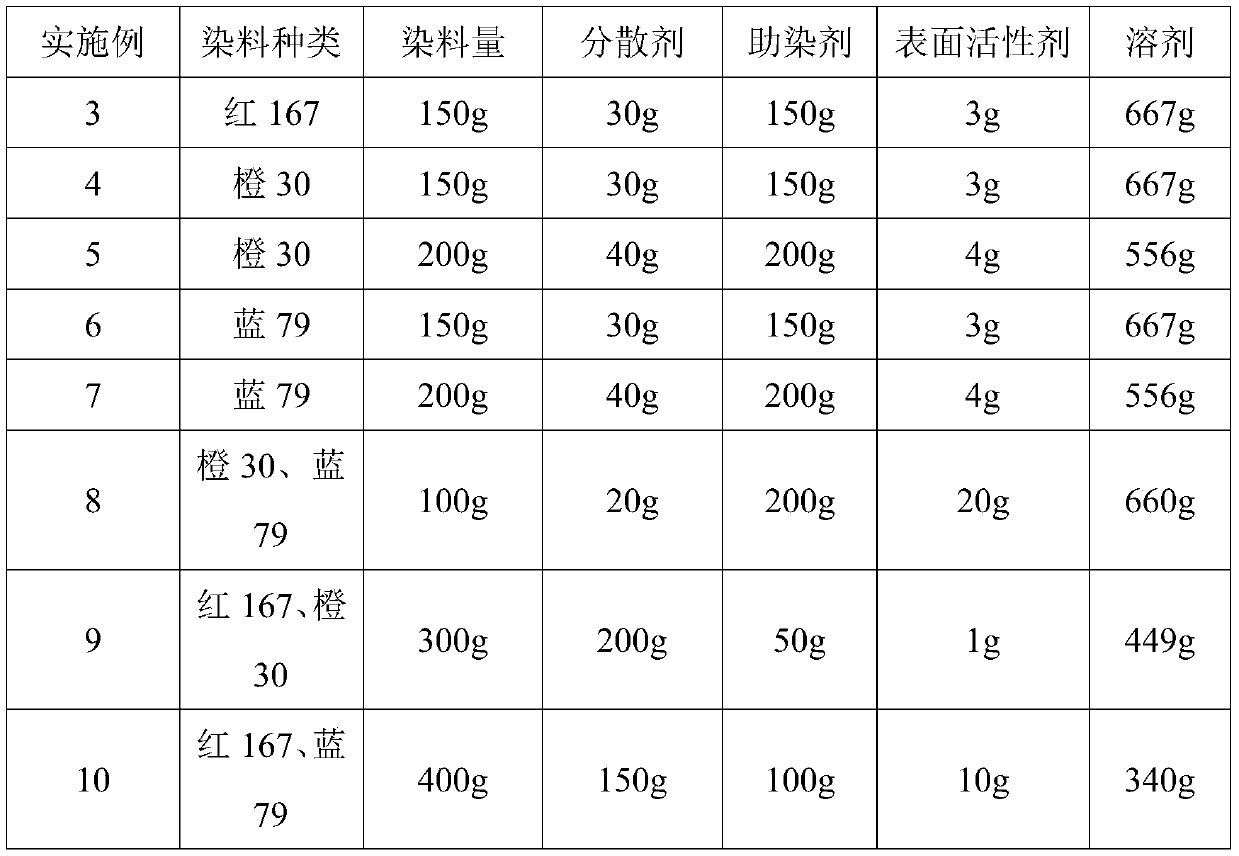

Examples

Embodiment 1

[0024] Mix 200g of Disperse Red 167, 40g of polycarboxylate, 4g of defoamer, and 756g of deionized water, pre-disperse and then add to sand mill for grinding to obtain Disperse Red 167 disperse dye paste. The range of the particle size after grinding is 0.1-1um.

Embodiment 2

[0026] Mix 200g of Disperse Red 167, 40g of alkylamine salt, 200g of ethyl acetate, 4g of defoamer, and 556g of deionized water, pre-disperse and then add to the sand mill for grinding to obtain Disperse Red 167 disperse dye paste. The range of the particle size after grinding is 0.1-1um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com