Zirconium dioxide catalyst supporting iron cobalt potassium, preparation method and application thereof

A technology of zirconium dioxide and iron cobalt potassium is applied in the application field of selective reduction of carbon dioxide to ethylene, can solve problems such as poor activity and low conversion rate, and achieves maintaining catalytic performance, good catalytic performance, excellent ethylene selectivity and The effect of carbon dioxide conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

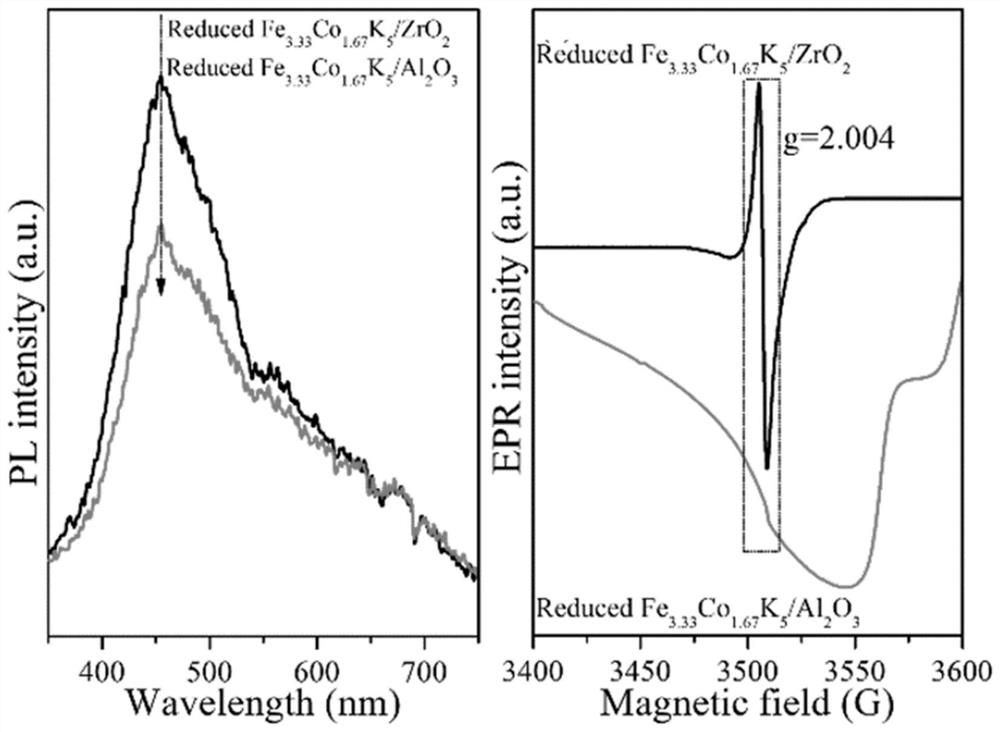

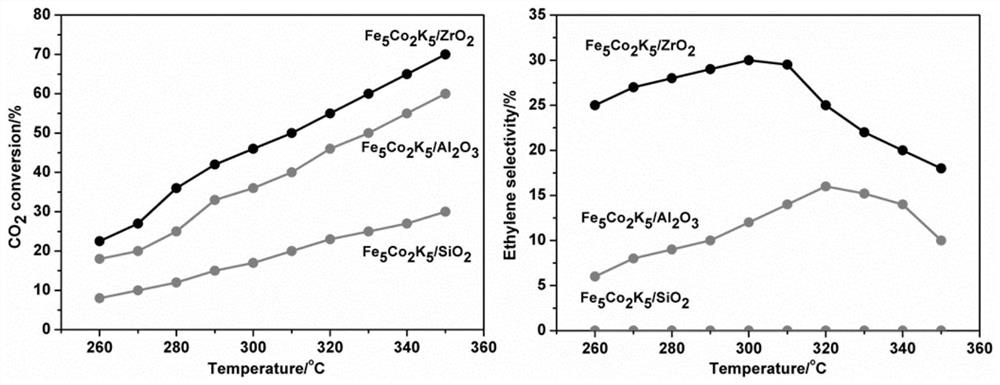

[0025] Fe 3.33 co 1.67 K 5 / ZrO 2 The catalyst was prepared by a one-step hydrothermal method, and Fe(NO 3 ) 3 9H 2 O, Co(NO 3 ) 3 ·6H 2 O. KNO 3 and ZrO 2 (The mass ratio is 5:2:5:100) were dissolved in deionized water together, and stirred for 12 hours to obtain a mixed precursor solution. Pour the mixed precursor solution into the reaction kettle, hydrothermally react at 140°C for 12h, centrifuge, and dry at 110°C to obtain Fe 3.33 co 1.67 K 5 / ZrO 2 catalyst.

Embodiment 2

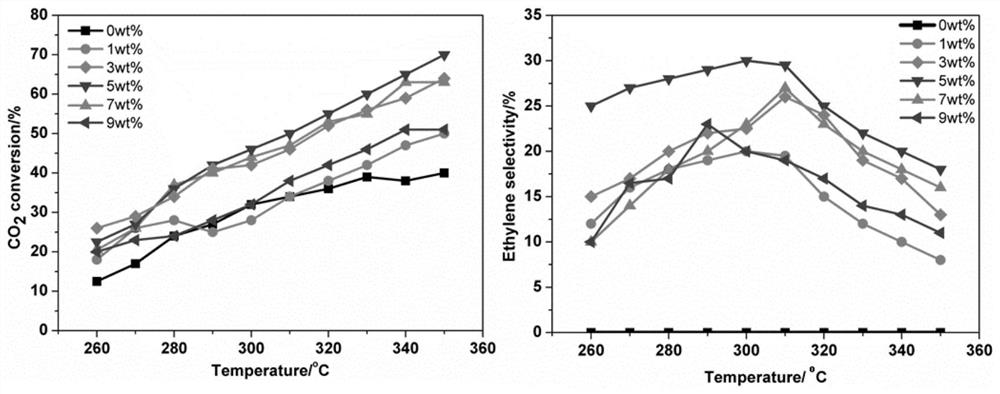

[0031] Preparation of FeCoK with total Fe and Co loadings of 0, 1, 3, 5, 7, 9 wt% 5 / ZrO 2 catalyst. In the same method as in Example 1, different mass ratios of Fe(NO 3 ) 3 9H 2 O and Co(NO 3 ) 3 ·6H 2 O dissolved.

Embodiment 3

[0033]Preparation of FeCoK / ZrO with K loadings of 0, 1, 3, 5, 7, 10 wt% 2 catalyst. In the same way as in Example 1, change KNO 3 the dissolution quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com