Method for preparing ethylene based on superparticles

A particle and ethylene technology, applied in the field of ethylene preparation based on superparticles, can solve the problems of low selectivity and poor stability, and achieve the effect of high ethylene selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

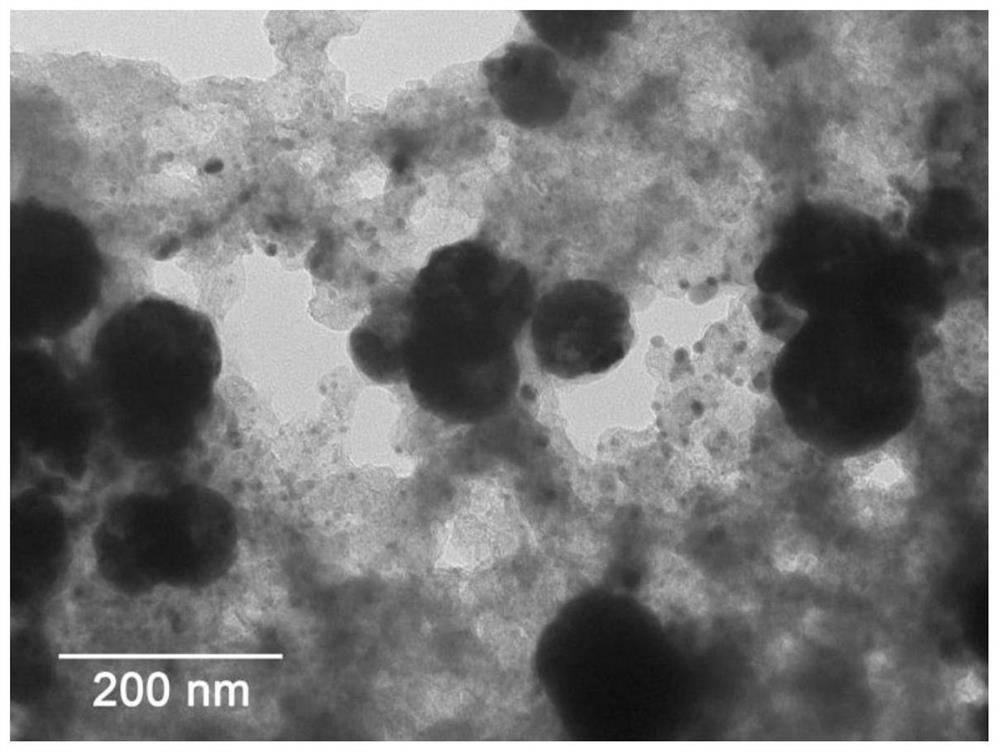

[0044] Cu 2 Preparation of O superparticles

[0045] Add 362mg of copper nitrate trihydrate, 3g of polyvinylpyrrolidone (average molecular weight 8000) and 30ml of diethylene glycol into a 50ml three-necked flask, seal it and vacuumize it for about 15min, and then inject argon to create inertness Gas atmosphere. The solution was then heated to 190° C. with stirring using a heating mantle within 30 min and then cooled to room temperature. The product was separated by centrifugation, and washed three times with deionized water and ethanol to obtain Cu 2 O superparticles.

Embodiment 1

[0047] Step 1) Preparation of Catalyst Ink

[0048] Take 5mg Cu 2 O superparticles, 2.5 mg carbon black and 30 μL Nafion solution (5wt%) were added to 970 μl isopropanol, and then ultrasonically used for more than 30 minutes to obtain a uniform dispersion;

[0049] Step 2) preparation of working electrode

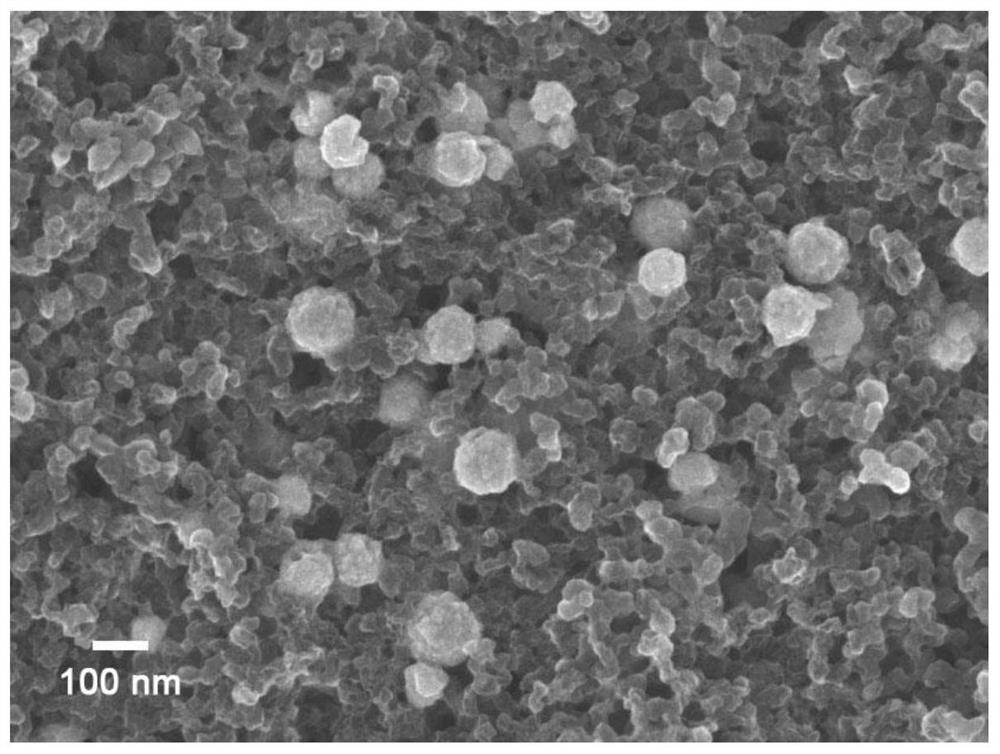

[0050] Take 10 μl of the catalyst ink in step 1), evenly drop-coat it on the surface of a glassy carbon electrode (5mm in diameter), and use an infrared lamp to dry it; figure 1 as shown, figure 1 for Cu 2 Scanning electron microscope picture of composite O superparticles and carbon black;

[0051] Step 3) Constant current pre-reduction of catalyst

[0052] The working electrode is installed in a typical three-electrode system H-type electrolytic cell. The silver-silver chloride electrode is used as the reference electrode, the platinum sheet electrode is used as the counter electrode, and the cathode and anode are separated by Nafion 117 membrane. Add 40ml of 0.1MKHC...

Embodiment 2

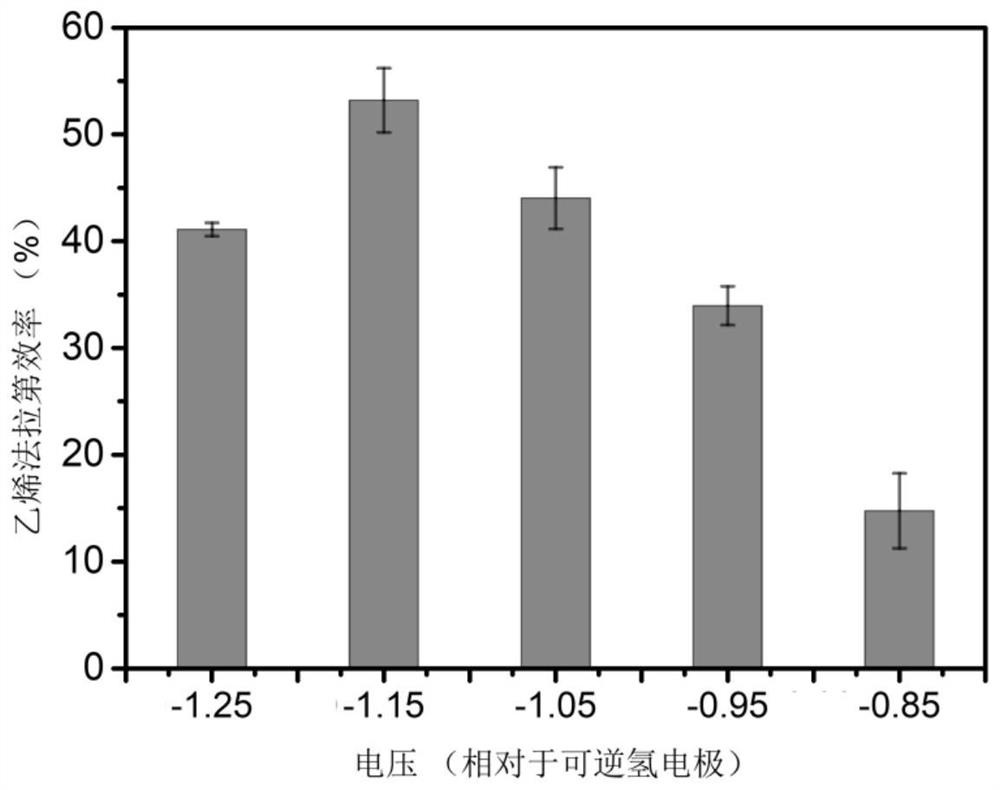

[0056] The specific operation steps are the same as in Example 1, except that in step 4), the constant voltage is changed to -0.85V, -0.95V, -1.05V and -1.25V (relative to the reversible hydrogen electrode) to carry out the electrocatalytic carbon dioxide reduction reaction. Correspondingly, the obtained ethylene Faradaic efficiencies were 15%, 34%, 44% and 41%, respectively. The corresponding ethylene Faradaic efficiency under more potential differences is as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com