Method of preparing acetylene by partial oxidization of natural gas

A technology for natural gas and acetylene, which is applied in the field of partial oxidation of natural gas to prepare acetylene to achieve the effects of reducing the loss of acetylene gas, increasing profits and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

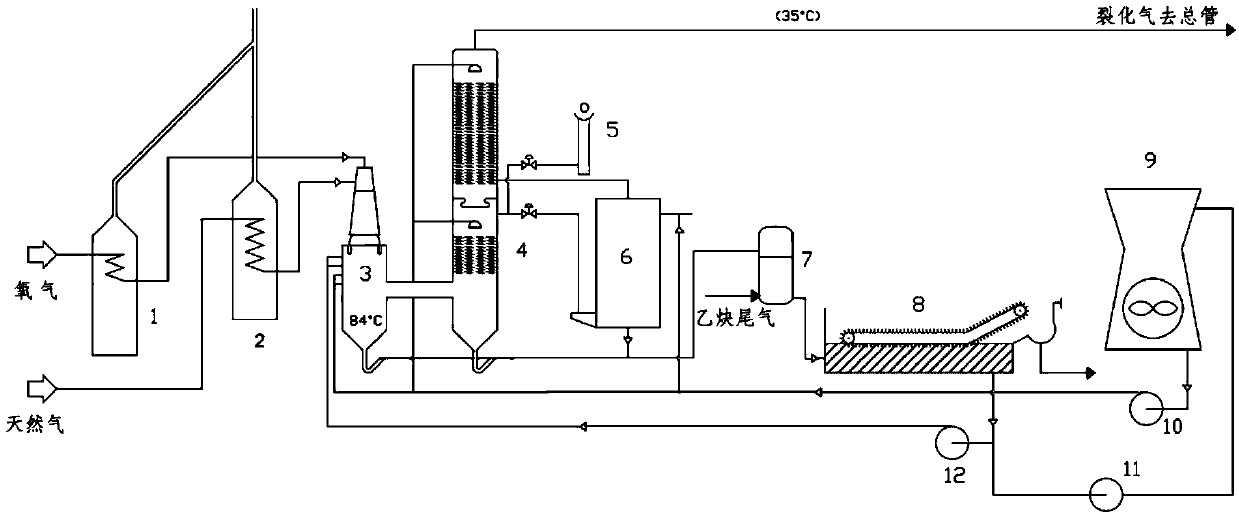

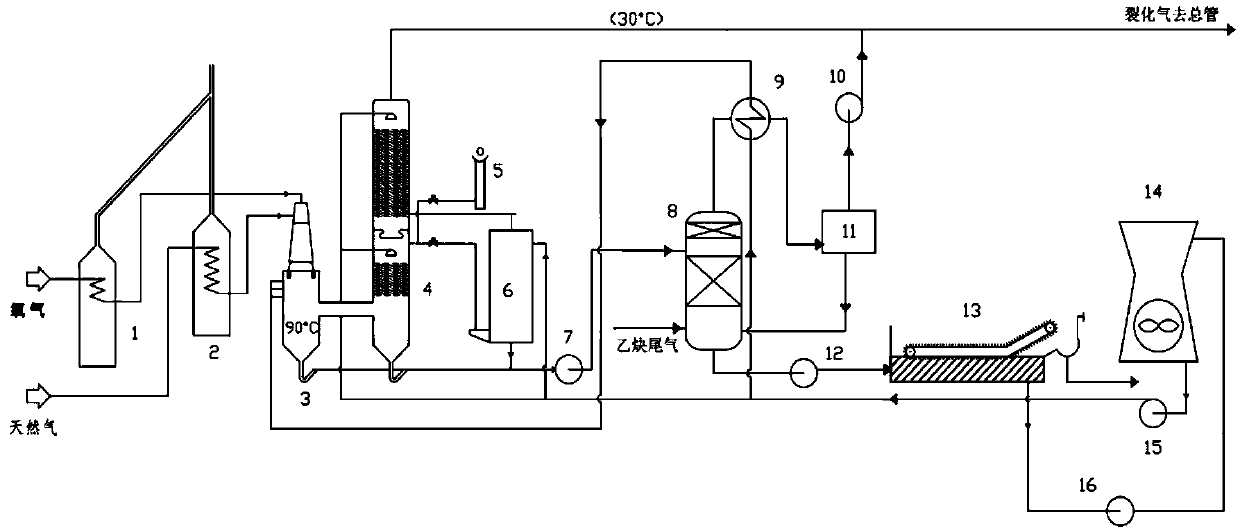

[0037] Adopt following device and method to prepare acetylene, specifically:

[0038] A. Send oxygen and natural gas with an oxygen ratio of 0.545 into oxygen preheating furnace 1 and natural gas preheating furnace 2 respectively, and after preheating to 600-650°C, enter into acetylene furnace 3 for partial oxidation reaction, through heat exchange After the heat-exchanged cold carbon black water provided by the device 9 is quenched, the cracked gas having a temperature of 89° C. and containing acetylene is obtained;

[0039] B. The cracked gas obtained in step A passes through the lower section of the cooling tower 4, the electrostatic precipitator 5 and the upper section of the cooling tower 4 in turn, and enters the cracked gas main pipe after being cooled to 35°C;

[0040] C. After the carbon black water produced in the acetylene furnace 3, the cooling tower 4 and the electrostatic precipitator 5 enters the carbon black water main pipe, it is delivered to the vacuum air st...

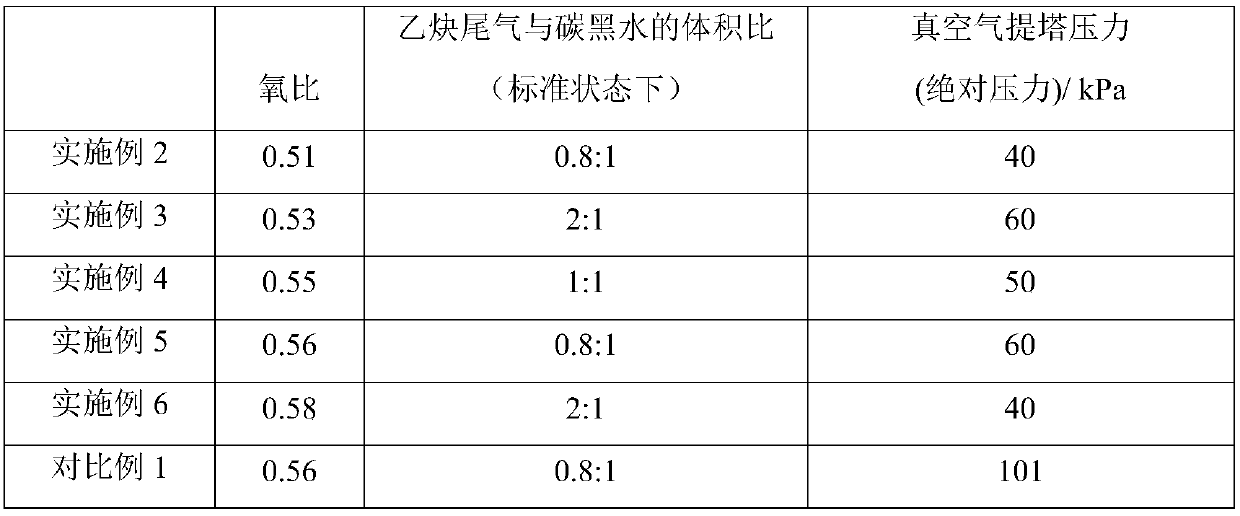

Embodiment 2-6 and comparative example 1

[0047] Examples 2-6 and Comparative Example 1 were carried out according to the conditions shown in Table 2, and the others were the same as Example 1.

[0048] Table 2 embodiment 2-6 and comparative example 1

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com