Method for Solving Edge Crack Defects of Cold-rolled High-strength Steel Above 780mpa Grade in Acid Rolling

A high-strength, steel-acid technology, applied in the direction of metal rolling, metal rolling, workpiece cooling devices, etc., can solve the problems of serious steel coil head and tail, uneven edge structure deformation, acid rolling edge crack defects, etc., and achieve improvement Yield and pass rate, improve product surface quality, improve the effect of coarse grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

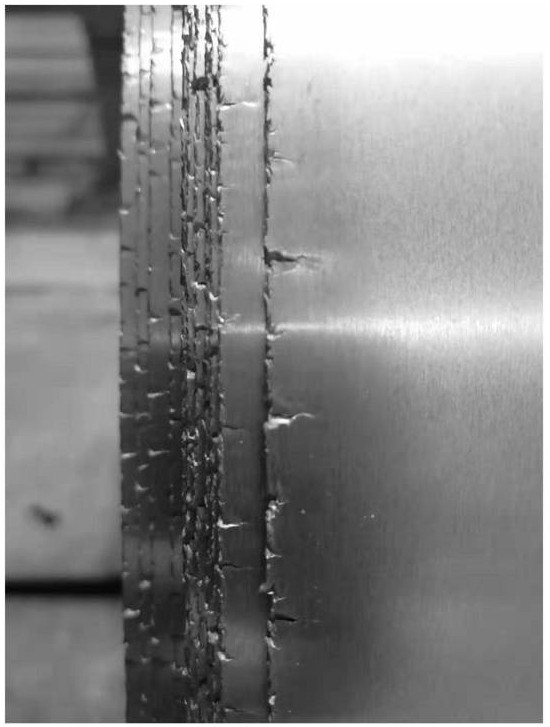

Image

Examples

Embodiment 1

[0034] In this embodiment, the steel type CR550 / 980DP, the thickness is 2.3mm, and the width is 1136mm. The method for solving the edge crack defect of cold-rolled high-strength steel above the 780MPa level includes continuous casting, heating, rough rolling, finish rolling, laminar cooling, and rolling. Take and slow cooling operation, concrete processing step is as follows:

[0035] (1) Continuous casting process: use chamfering crystallizer to produce chamfering continuous casting slab, the chamfering angle is 30°, and the length is 57mm;

[0036] (2) Heating process, the heating temperature is 1248°C, the difference between the same plate is 20°C, and the difference between furnaces is 19°C;

[0037] (3) Rough rolling process: the fixed width of the fixed width machine is 50mm, and 3+3 passes and edge heaters are used to compensate the edge temperature of 35mm on both sides at 50°C;

[0038] (4) Finish rolling process: high temperature start rolling at 1089°C, cooling wat...

Embodiment 2

[0044] In this embodiment, the steel type CR550 / 980DP, the thickness is 2.4mm, and the width is 1453mm. The method for solving the defect of edge cracking of cold-rolled high-strength steel above 780MPa level includes continuous casting, heating, rough rolling, finish rolling, laminar cooling, coiling Take and slow cooling operation, concrete processing step is as follows:

[0045] (1) Continuous casting process: use chamfering crystallizer to produce chamfering continuous casting slab, the chamfering angle is 20°, and the length is 46mm;

[0046] (2) Heating process, the heating temperature is 1270°C, the difference between the same plate is 18°C, and the difference between furnaces is 20°C;

[0047] (3) Rough rolling process: the fixed width of the fixed width machine is 47mm, and the edge temperature compensation of 48°C is performed on the 55mm of both sides by using 3+3 passes and edge heaters;

[0048] (4) Finish rolling process: high temperature start rolling at 1090°C...

Embodiment 3

[0054] In this embodiment, the steel type CR550 / 980DP, the thickness is 2.5mm, and the width is 1200mm. The method for solving the defect of edge cracking of cold-rolled high-strength steel above the 780MPa level includes continuous casting, heating, rough rolling, finish rolling, laminar cooling, and coiling. Take and slow cooling operation, concrete processing step is as follows:

[0055] (1) Continuous casting process: use chamfering crystallizer to produce chamfering continuous casting slab, the chamfering angle is 38°, and the length is 70mm;

[0056] (2) Heating process, the heating temperature is 1240°C, the difference between the same plate is 18.5°C, and the difference between furnaces is 17°C;

[0057] (3) Rough rolling process: the fixed width of the fixed width machine is 58mm, and the edge temperature compensation of 45°C is carried out on the 22mm of both sides by using 3+3 passes and edge heaters;

[0058] (4) Finish rolling process: high-temperature rolling at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com