Boron-free medium-low-nickel high-strength high-hardenability marine steel thick plate and preparation method thereof

A technology of high hardenability and marine steel, which is applied in the field of material processing, can solve difficult problems such as performance uniformity and hardenability, and achieve the effects of cost control, inhibition of nucleation and growth, and improvement of hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

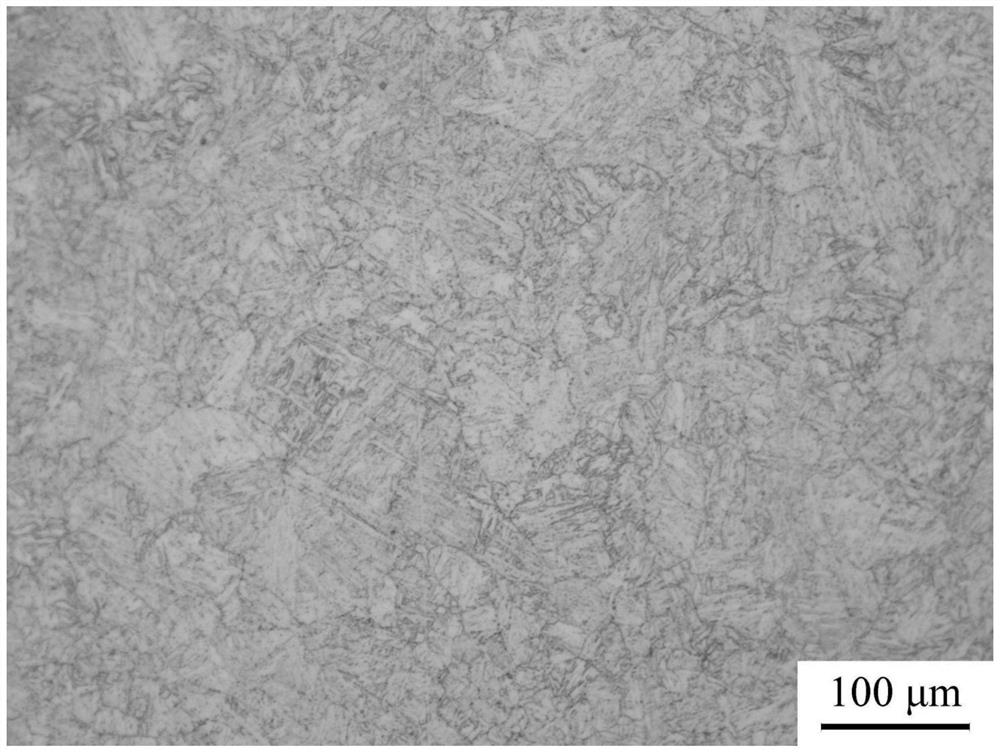

Embodiment 1

[0044] A boron-free medium-nickel high-strength high-hardenability marine steel thick plate provided in this example has the following chemical composition and mass percentage: C: 0.088%; Si: 0.24%; Mn: 0.73%; Ni: 1.98% ; Cr: 0.61%; Mo: 0.35%; V: 0.09%; N: 0.0063%; Al: 0.024%; Cu: 0.32%;

[0045] The production method of this embodiment includes smelting, continuous casting, hot rolling and heat treatment processes.

[0046] 1. Smelting process: Carry out vacuum induction smelting and electroslag remelting according to the components and their contents in Example 1, control the nickel content in the converter, and cast into slabs;

[0047] 2. Hot rolling process: put the continuous casting slab obtained through the smelting and continuous casting process in the heating furnace, heat and keep it uniform, the temperature is 1280 ℃, and the thickness of the slab is 300mm; the two-stage differential temperature rolling process is adopted to start The temperature of the billet is ...

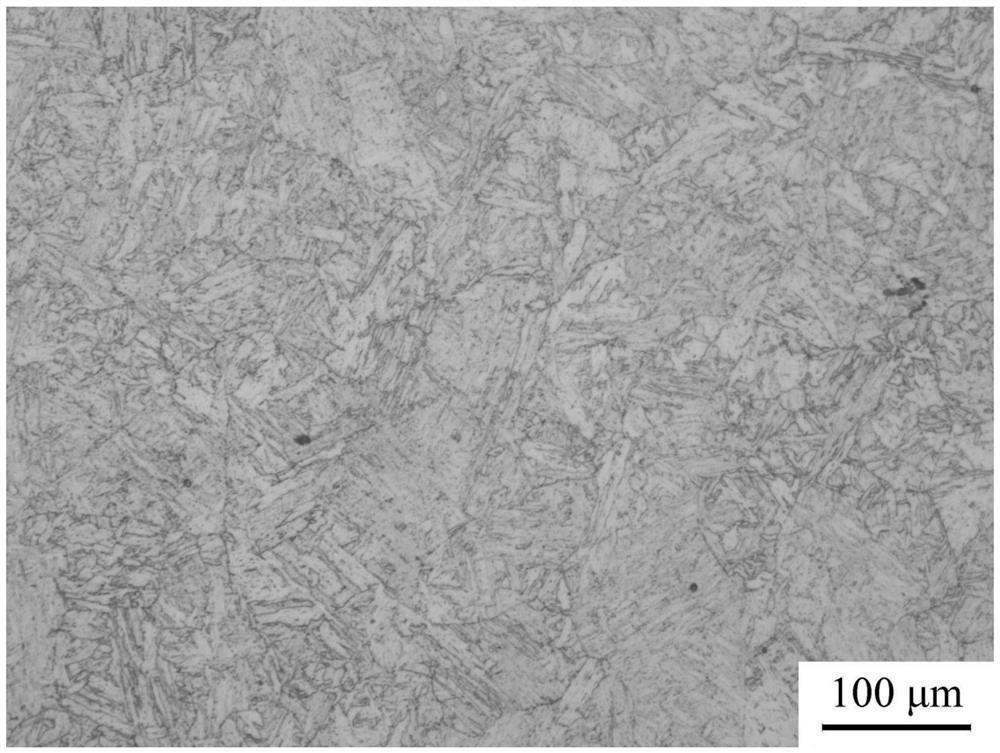

Embodiment 2

[0051] A boron-free, low-nickel, high-strength, high-hardenability marine steel thick plate provided in this example has the following chemical composition and mass percentage: C: 0.096%; Si: 0.28%; Mn: 0.73%; Ni: 1.55% ; Cr: 0.77%; Mo: 0.35%; V: 0.15%; N: 0.0079%; Al: 0.026%; Cu: 0.37%;

[0052] The production method of this embodiment includes smelting, continuous casting, hot rolling, and heat treatment processes.

[0053] 1. Smelting process: Carry out vacuum induction smelting and electroslag remelting according to the components and their contents in Example 2, control the nickel content in the converter, and cast into slabs;

[0054] 2. Hot rolling process: the continuous casting slab obtained through smelting and continuous casting process is placed in the heating furnace, heated and kept uniform, the temperature is 1250 ℃, and the thickness of the slab is 180mm; the two-stage differential temperature rolling process is adopted, and the The temperature of the billet i...

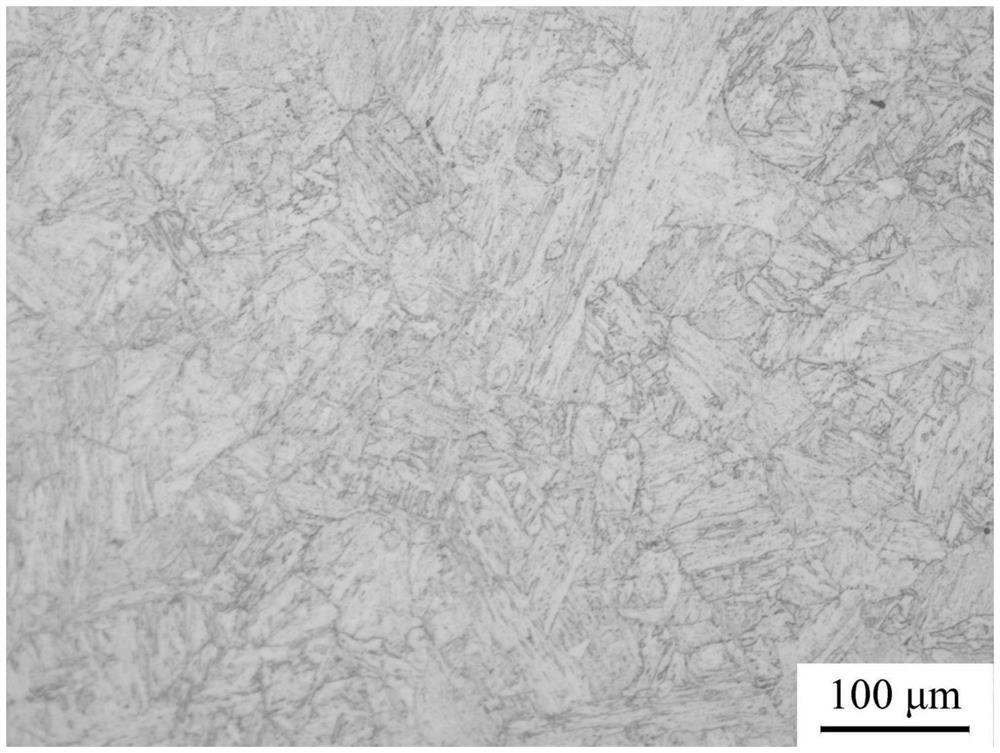

Embodiment 3

[0058] A boron-free, low-nickel, high-strength, high-hardenability marine steel thick plate provided in this example has the following chemical composition and mass percentage: C: 0.094%; Si: 0.32%; Mn: 0.80%; Ni: 1.67 %; Cr: 0.78%; Mo: 0.38%; V: 0.17%; N: 0.0092%; Al: 0.029%; Cu: 0.35%;

[0059] The production method of this embodiment includes smelting, continuous casting, hot rolling, and heat treatment processes.

[0060] 1. Smelting process: Carry out vacuum induction smelting and electroslag remelting according to the components and their contents in Example 3, control the nickel content in the converter, and cast into slabs;

[0061] 2. Hot rolling process: the continuous casting slab obtained through the smelting and continuous casting process is placed in a heating furnace, heated and kept uniform, the temperature is 1270°C, and the thickness of the slab is 250mm; a two-stage differential temperature rolling process is adopted to start The temperature of the billet i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| -20°c impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com