Regenerant for thermal regeneration of asphalt mixture

A technology of asphalt mixture and rejuvenating agent, which is used in building thermal insulation materials, building components, buildings, etc. to prevent precipitation, reduce volatilization, and facilitate use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

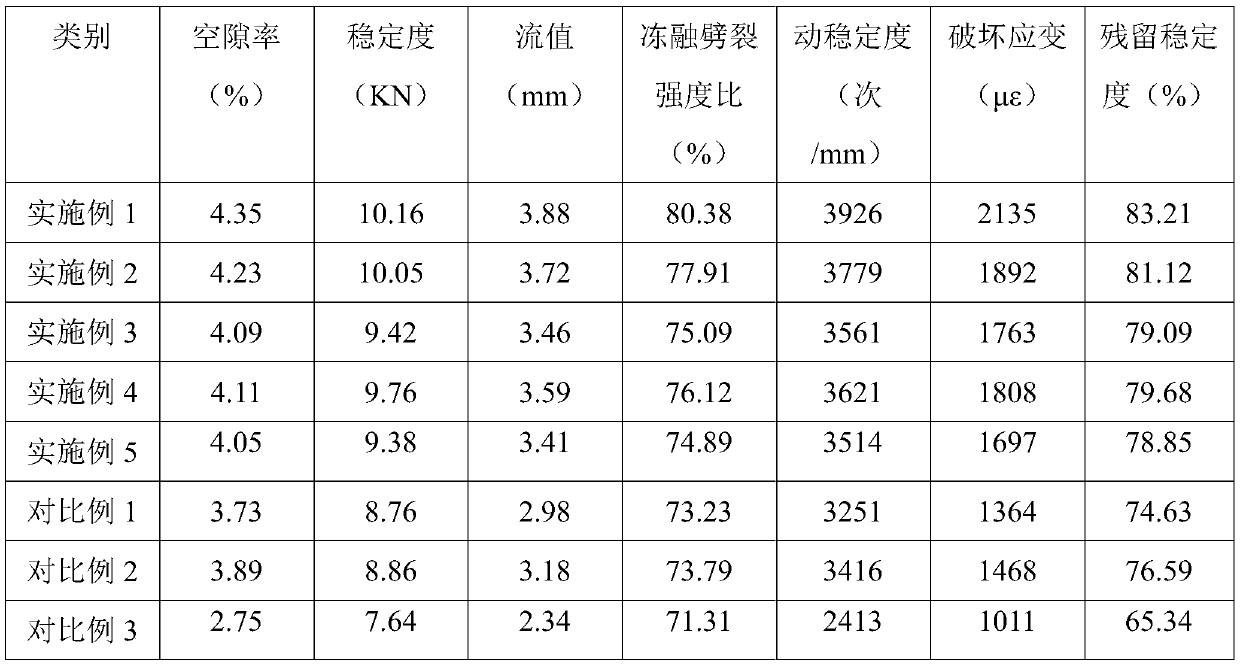

Examples

Embodiment 1

[0031]A heat regeneration asphalt mixture regeneration agent comprises the following raw materials in parts by weight: 10 parts of dipentene, 10 parts of benzofuran, 5 parts of pine tar, 5 parts of tall oil, 40 parts of heavy oil, 20 parts of of waste lubricating oil, 10 parts of waste engine oil, and 8 parts of biologically active powder; in order to further reduce the impact of volatile harmful substances in the heavy oil, and disperse the heavy oil without affecting the quality of regenerated asphalt, the biologically active powder is, using Alcaligenes faecalis expands and breeds in oily sewage, and the obtained breeding liquid is filtered and dried at low temperature to obtain biologically active powder. The heavy oil is initially hydrolyzed by using the breeding liquid of Alcaligenes faecalis in an alkaline environment. Through protein denaturation, precipitation binds heavy metals in heavy oil; at the same time, the bacteria in the breeding fluid absorb harmful substance...

Embodiment 2

[0039] A heat regeneration asphalt mixture regeneration agent comprises the following raw materials in parts by weight: 10 parts of dipentene, 10 parts of benzofuran, 2 parts of pine tar, 2 parts of tall oil, 30 parts of heavy oil, 10 parts of of waste lubricating oil, 10 parts of waste engine oil, and 2 parts of bioactive powder; all the other formulas and steps are the same as in Example 1.

Embodiment 3

[0041] A heat regeneration asphalt mixture regeneration agent comprises the following raw materials in parts by weight: 20 parts of dipentene, 20 parts of benzofuran, 10 parts of pine tar, 10 parts of tall oil, 60 parts of heavy oil, 30 parts of waste lubricating oil, 20 parts of waste engine oil, 10 parts of bioactive powder; all the other formulas and steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com