Double-furnace double-combustion flue-cured tobacco equipment and process

The technology of flue-cured tobacco and equipment is applied in the field of intelligent high-temperature, high-efficiency and energy-saving dual-furnace and dual-burning flue-cured tobacco equipment and technology, and can solve the problems of insufficient utilization of biomass thermal energy storage, high biomass processing cost, and high emission of combustion pollutants. To achieve the effect of improving the utilization efficiency of biomass energy, improving the production efficiency of tobacco leaves, and improving the utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

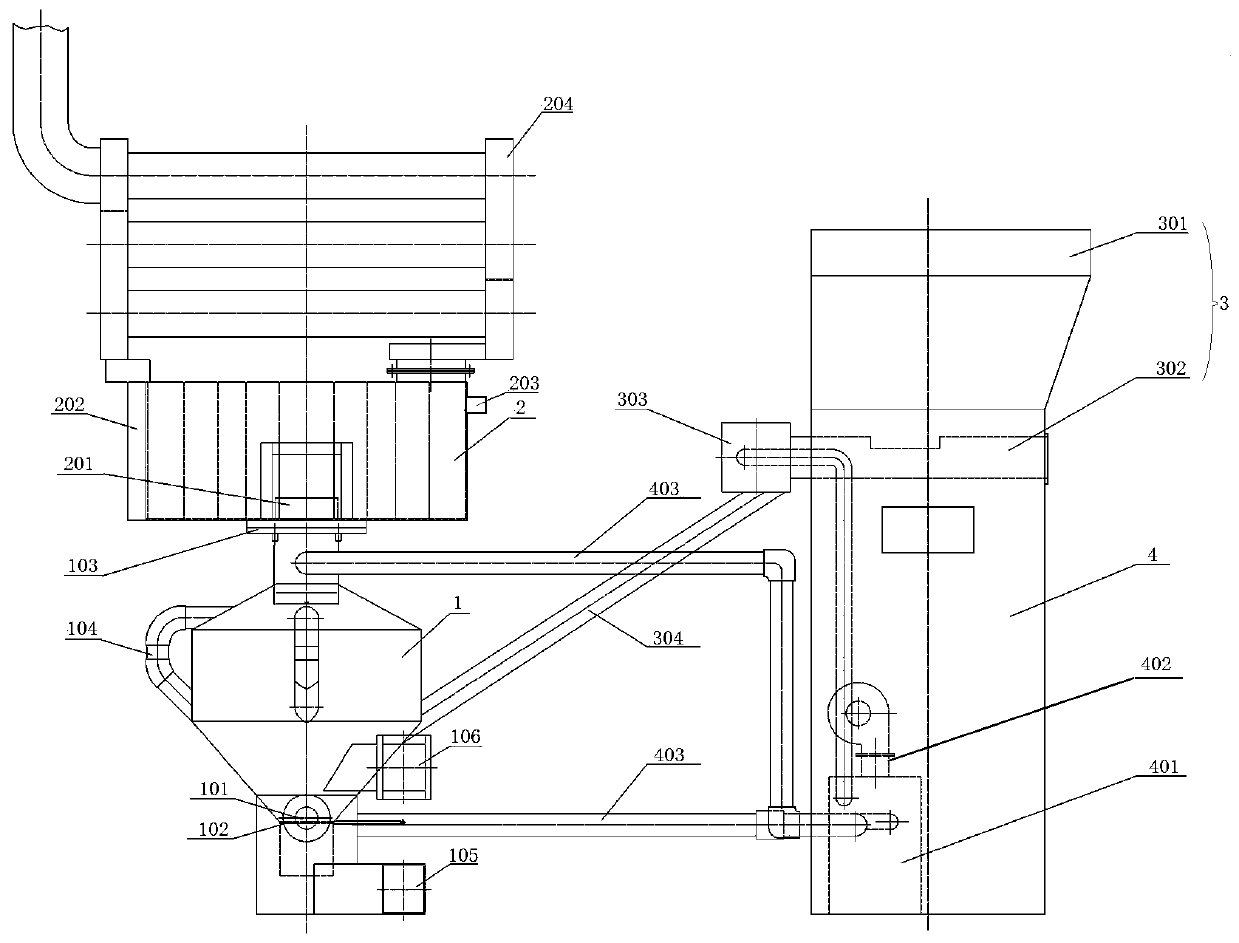

[0028] Such as figure 1 Shown is a flue-cured tobacco equipment with double ovens and double combustion of the present invention, which includes a flue-cured tobacco chamber and a heating chamber connected to the flue-cured tobacco chamber, a combustion furnace with double burners is arranged in the heating chamber, and a material storage unit is arranged outside the heating chamber 3 and body 4; the combustion furnace includes a first furnace body 1 and a second furnace body 2 connected in series, the first furnace body is provided with an air-cooled igniter 101 and a fuel burner 102 at the bottom, and a gas discharge port is provided at the top 103, a number of cooling pipes 104 are arranged on the outside of the first furnace body; the lower part of the second furnace body communicates with the gas discharge port, a gas burner 201 is arranged on the lower part of the second furnace body, and a gas burner 201 is arranged on the side. The explosion-proof valve 203 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com