A kind of highly transparent thermoplastic polyurethane elastomer for blown film and preparation method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of polyurethane materials, can solve the problems of poor transparency and complicated preparation methods of polyurethane, and achieve the effects of excellent mechanical properties, excellent mechanical properties, and suitable melt index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

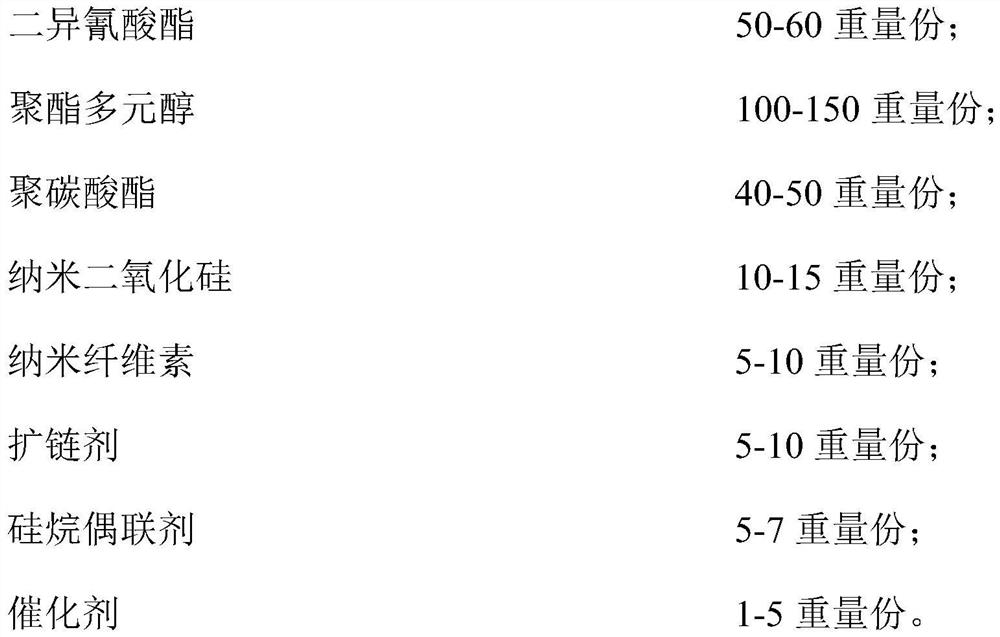

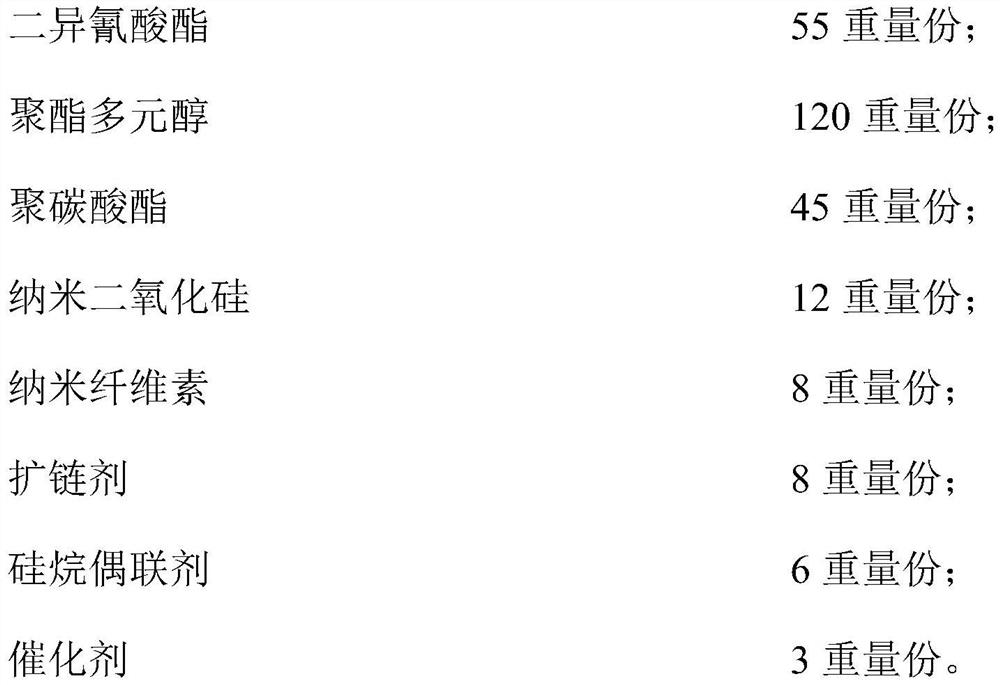

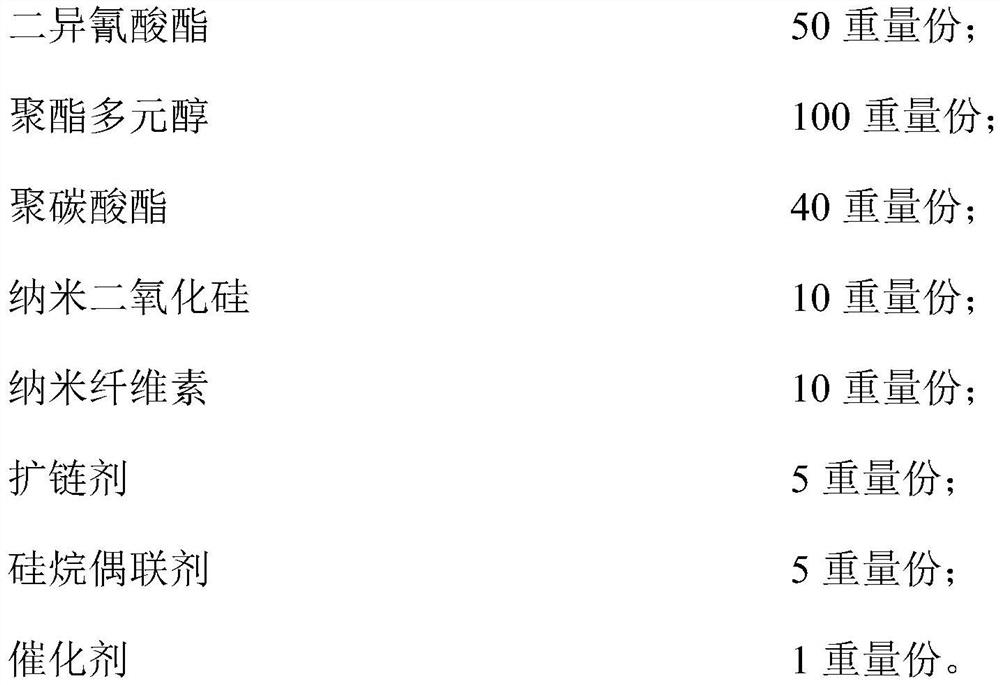

[0051] A highly transparent thermoplastic polyurethane elastomer for blown film, consisting of the following components in parts by weight:

[0052]

[0053] Wherein, the diisocyanate is a composition composed of 3,3'-dimethyl-4,4'-biphenyl diisocyanate and dicyclohexylmethane diisocyanate in a molar ratio of 1.5:1; the polyester polyol has an average molecular weight of 1500 polybutylene adipate; the molecular weight of polycarbonate is 15000; the average particle size of nano-silica is 80nm; the diameter of nano-cellulose is 40-60nm, and the aspect ratio is 250-300; The agent is ethylene glycol; the silane coupling agent is isobutyltriethoxysilane; the catalyst is stannous octoate.

[0054] The preparation method is as follows:

[0055] (1) polyester polyol, nanocellulose, chain extender and catalyst are mixed;

[0056] (2) diisocyanate, polycarbonate, nano silicon dioxide and silane coupling agent are mixed;

[0057] (3) After mixing the mixture obtained in step (1) a...

Embodiment 2-4

[0059] The only difference from Example 1 is that the molar ratio of 3,3'-dimethyl-4,4'-biphenyl diisocyanate to dicyclohexylmethane diisocyanate is 2.5:1 (Example 2), 3:1 (Example 3), 1:1 (Example 4).

Embodiment 5-6

[0061] The only difference from Example 1 is that the diisocyanate is 3,3'-dimethyl-4,4'-biphenyl diisocyanate (Example 5) and dicyclohexylmethane diisocyanate (Example 6).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com