Fruit and vegetable microcapsule powder, fruit and vegetable microcapsule-potato powder, and preparation methods thereof

A technology of potato flour and microcapsule powder, which is applied in food freezing, food forming, food science, etc., can solve the problem of large losses and achieve the effect of meeting nutritional and energy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

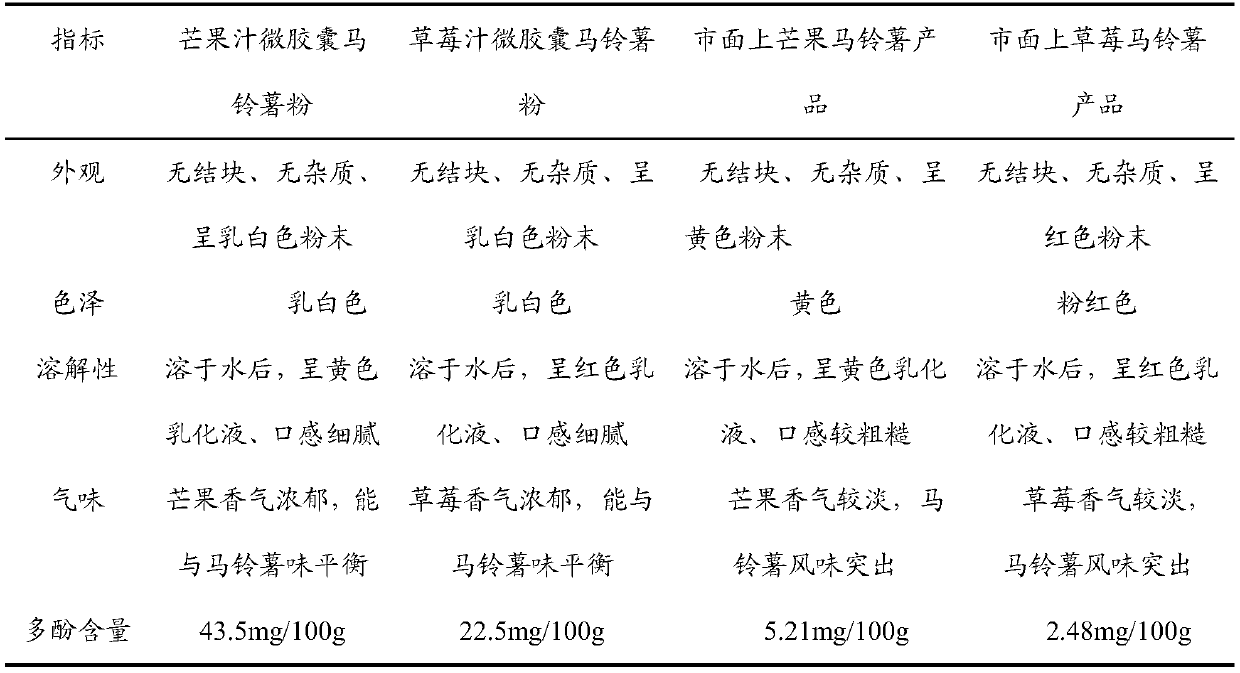

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of fruit and vegetable microcapsule powder, comprises the following steps:

[0028] 1) crushing fruits and vegetables and beating to obtain fruit and vegetable slurry; adding 0.5-1.0% of fruit and vegetable mass citric acid and fruit and vegetable mass 1.0-1.5% vitamin C during the beating process;

[0029] 2) enzymatically hydrolyzing the fruit and vegetable slurry obtained in step 1) to obtain an enzymatic hydrolysis solution; the enzyme for enzymatic hydrolysis includes pectinase, the temperature of the enzymatic hydrolysis is 40-45° C., and the enzymatic hydrolysis time is 2-3 hours;

[0030] 3) Squeeze the enzymolysis solution obtained in step 2) to obtain squeezed juice;

[0031] 4) performing coarse filtration and ultrafiltration on the squeezed juice obtained in step 3) to obtain a filtrate;

[0032] 5) Concentrate the filtrate obtained in step 4) in a vacuum to obtain concentrated juice; the conditions for th...

Embodiment 1

[0054] How to prepare Instant Potato Flour:

[0055] (1) Select fresh potatoes without lesions and rot;

[0056] (2) wash away the silt foreign material on potato surface, remove epidermis;

[0057] (3) Cooking: put the processed potatoes in step (2) into a steamer for steam cooking for 20 minutes, and the cooking temperature is 105° C.;

[0058] (4) Refining: put the boiled potatoes on the beater, add water to the beater, the mass ratio of potatoes to water is 1:6, the beating time is 6 minutes, and the beater speed is 750 rpm, and the obtained Potato pulp;

[0059] (5) Colloid mill: Define the potato pulp on the colloid mill for 1.5 minutes; add β-cyclodextrin with 4% potato pulp quality, mix evenly, and avoid potato caking;

[0060] (6) Heat pump drying: use DHG-9245A heat pump dryer, dry at 70°C for 7 hours, until the moisture content is 10%;

[0061] (7) Powdering: adopt ST-02A high-speed pulverizer, control pulverization particle size at 80 mesh.

[0062] The prepar...

Embodiment 2

[0076] How to prepare Instant Potato Flour:

[0077] (1) Select fresh potatoes without lesions and rot;

[0078] (2) wash away the silt foreign material on potato surface, remove epidermis;

[0079] (3) Cooking: put the potatoes treated in step (2) into a steamer and steam cook for 30 minutes at a cooking temperature of 107° C. to fully gelatinize the potato flour and passivate the enzymes in the potatoes;

[0080] (4) Refining: Put the boiled potatoes on the beater, add water to the beater, the mass ratio of potatoes and water is 1:5, the beating time is 8 minutes, and the beater speed is 700 rpm, and the obtained Potato pulp;

[0081] (5) Colloid mill: Define the potato pulp on the colloid mill for 2 minutes; add 3% beta-cyclodextrin of the potato pulp quality, mix evenly, and avoid potato caking;

[0082] (6) Heat pump drying: DHG-9245A heat pump dryer with energy saving and high quality is adopted, and dried at 65°C for 7.5 hours;

[0083] (7) Powdering: adopt ST-02A h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com