Fly ash reinforced foam forming device for oil field and application thereof

A technology for fly ash and foam is applied in the fields of fly ash solid waste utilization technology and equipment and oil and gas field development engineering, which can solve the problems of fly ash agglomeration, particle deposition, and fly ash exposure to the air, and achieves a reduction in construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

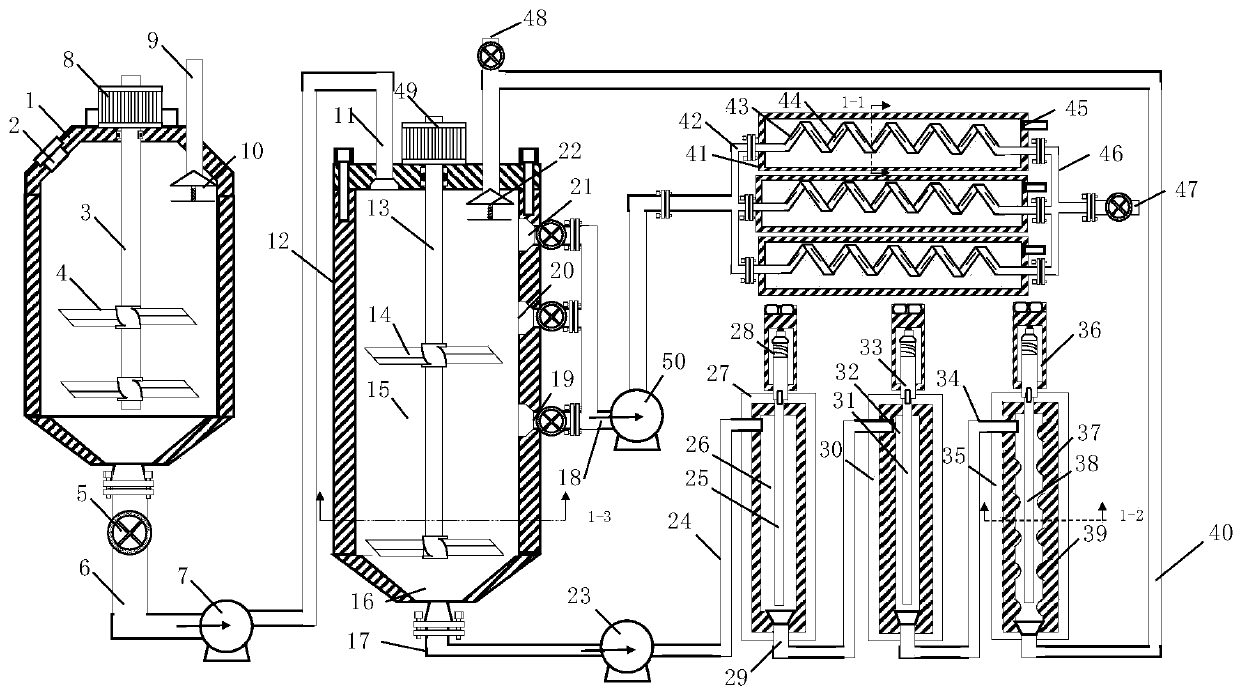

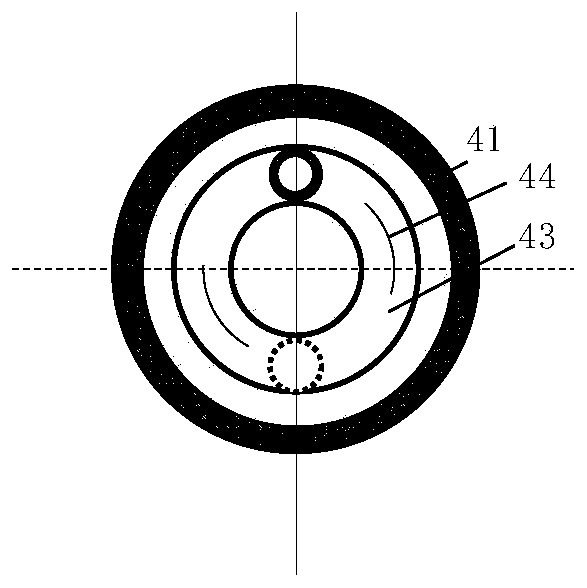

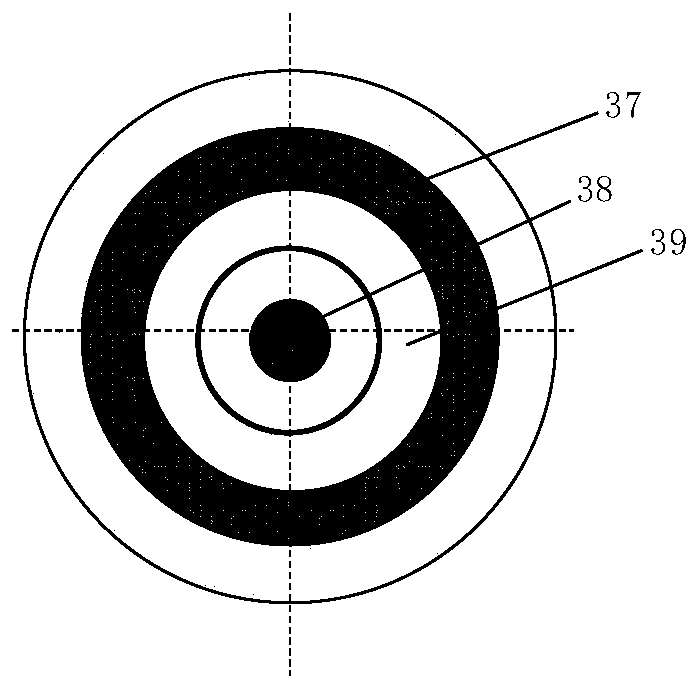

[0071] The structural representation of the fly ash reinforced foam forming device provided by the invention is as follows figure 1 As shown, it includes fly ash and foaming agent mixer 1, fly ash dispersion liquid splitter 12 (fly ash dispersion liquid splitter cavity 15), fly ash primary ultrasonic disperser 26, fly ash two Level ultrasonic disperser 32, fly ash three-level ultrasonic disperser 37, fly ash reinforced foam generator 41. The top of the fly ash and foaming agent mixer tank body 1 is provided with a feed inlet 2, a first injection port 9 of the foaming agent solution and a mixing agitator (comprising a mixing and stirring motor, a mixing and stirring rotating shaft 3 and a mixing and stirring paddle 4 ), the bottom is in communication with the first circulating pump 7 through the fly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com