High-activity superfine mineral admixture and preparation method thereof

A technology of mineral admixture and high activity, which is applied in the field of concrete admixtures, can solve the problems of complex preparation process and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] For the second solution of the present invention, the present invention proposes a kind of preparation method of highly active ultrafine mineral admixture, comprises the steps:

[0017] Drying process, mixing process, coarse grinding process and fine grinding process. Among them, the drying process is specifically drying the granite powder and slag to a moisture content of ≤3%, so as to avoid the smooth progress of the grinding process due to excessive raw material humidity during the grinding process. Preferably, the granite powder and slag are separately Drying; the mixing process is specifically mixing the dried granite powder, dried slag, fly ash, enhanced activation material, activator and desulfurized gypsum in proportion to obtain the first mixture; the coarse grinding process is Grinding the above first mixture to a specific surface area ≥ 400m 2 / kg to obtain the second mixture; the fine grinding process is to grind the above-mentioned second mixture to a spec...

Embodiment 1~5

[0030] Embodiments 1 to 5 provide 5 different highly active ultrafine mineral admixtures respectively, which are obtained through the following steps:

[0031] Mix the dried granite powder, dried slag, fly ash, activator, reinforcing and activating material and desulfurized gypsum according to a certain ratio, and then get high-quality powder after coarse grinding, sieving, fine grinding and sieving Active microfine mineral admixture.

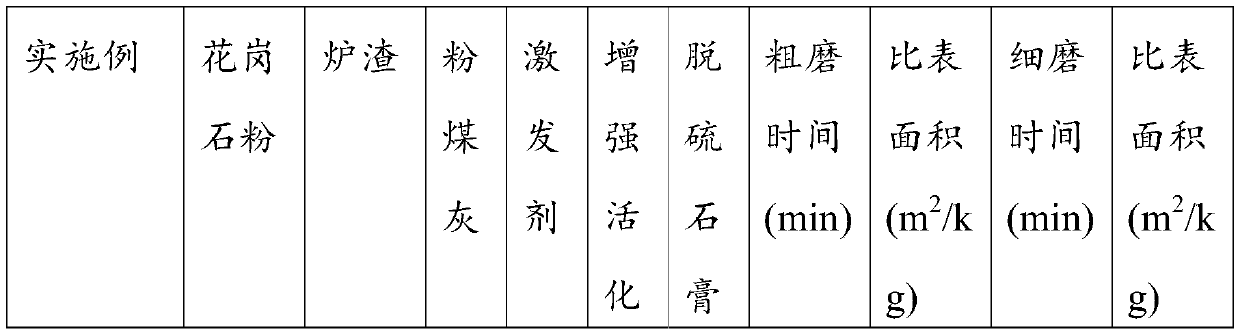

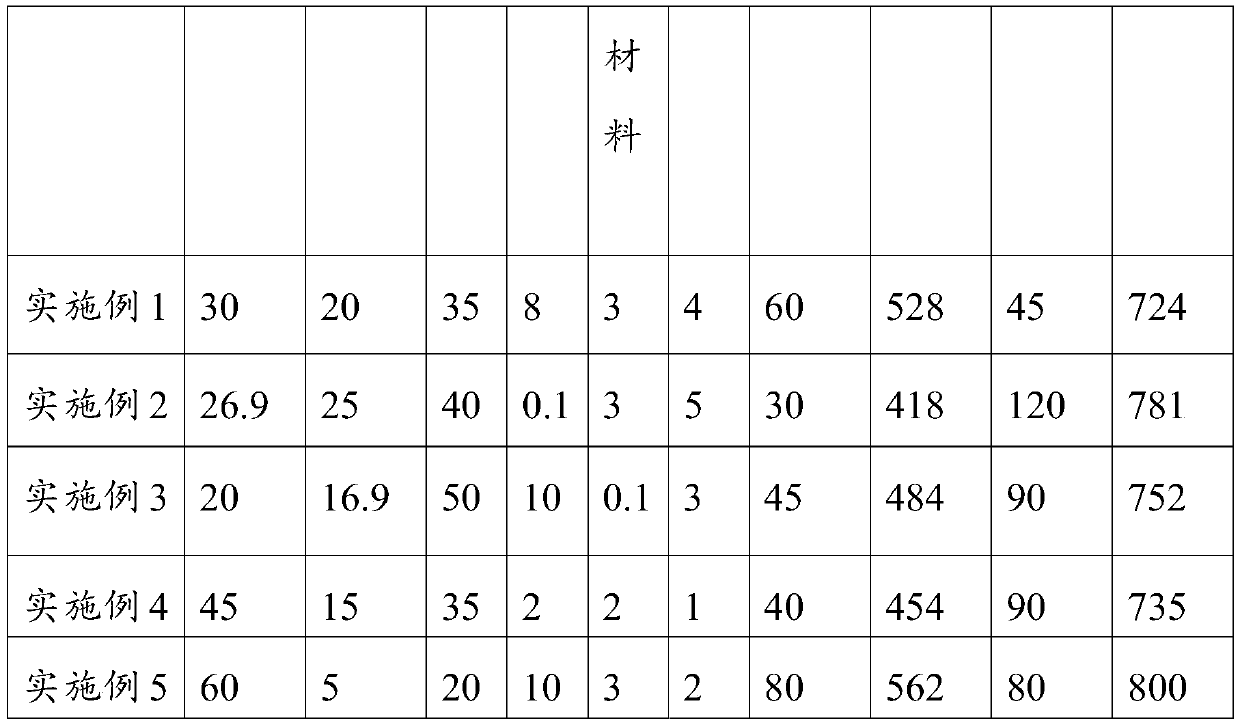

[0032] See Table 1 for the raw material proportions and process parameters of the highly active ultrafine mineral admixture obtained in Examples 1-5.

[0033] Table 1

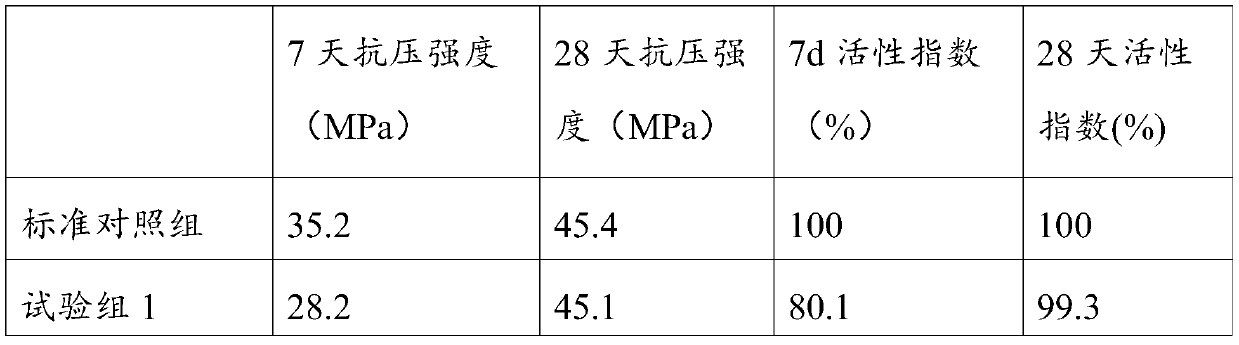

[0034]

[0035]

[0036] As can be seen from Table 1, by adopting the raw materials of the present invention and strictly controlling the process parameters in the present invention, such as steel ball or steel forging gradation, ball milling time, etc., specific surface area ≥ 700m can be obtained 2 / kg of highly active ultrafine mineral admixtures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com