A kind of preparation method of anti-pressure emulsion explosive

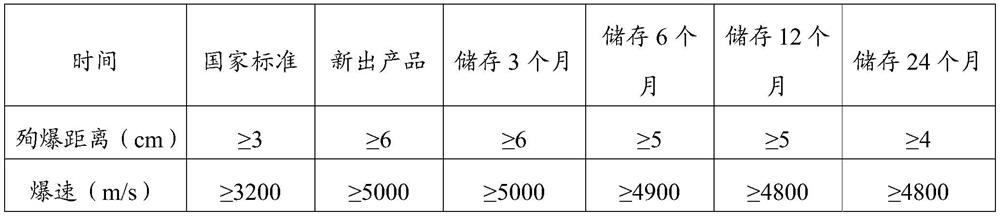

A technology of emulsified explosives and emulsified matrix, which is applied in the direction of explosives processing equipment, explosives, explosive composite components, etc., can solve the problems of poor product pressure resistance, complex geological environment, and low safety factor, and achieve strong anti-dynamic and static pressure. The effect of high detonation velocity and explosive power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The present invention provides a kind of preparation method of anti-pressure type emulsion explosive, comprises the following steps:

[0012] Prepare a sensitizer and an emulsification matrix respectively, add the sensitizer to the emulsification matrix and mix uniformly to obtain an emulsion explosive;

[0013] When the charge temperature is 45-60°C, the sensitizer includes 15-25% by mass percent of sodium nitrite, 5-10% of zinc nitrate, 5-10% of sodium thiocyanate and 55-75% % of water;

[0014] When the charge temperature is 60-90°C, the sensitizer includes 15-25% by mass percent of sodium nitrite, 10-20% of zinc nitrate, 10-20% of calcium nitrate and 35-65% of water.

[0015] It can be seen from the above description that the beneficial effect of the present invention lies in that the preparation method of the pressure-resistant emulsion explosive provided by the present invention adopts a chemical sensitization method for the preparation of the emulsion explosive...

Embodiment 1

[0022] A preparation method of a pressure-resistant emulsion explosive, specifically comprising the following steps:

[0023] 1) Preparation of sensitizer: 20 kg of sodium nitrite, 6 kg of zinc nitrate, and 10 kg of sodium thiocyanate were mixed and dissolved in 64 kg of water with a water temperature of 25° C. to obtain a sensitizer;

[0024] 2) Preparation of emulsification matrix: Mix 38kg of sp-80 emulsifier and 62kg of composite wax to prepare an oil phase solution, mix 830kg of ammonium nitrate, 60kg of sodium nitrate and 110kg of water to obtain a water phase solution with a crystallization point of 86°C , Take 940kg of water phase solution and 60kg of oil phase solution, emulsify at 90°C to obtain emulsification matrix, cool the emulsification matrix by steel belt, the temperature of the emulsification matrix is 45°C, and the density is 1.40g / cm 3 ;

[0025] 3) Prepare emulsified explosives: add the sensitizer to the emulsified matrix cooled to 45°C by pumping and m...

Embodiment 2

[0037] A preparation method of a pressure-resistant emulsion explosive, specifically comprising the following steps:

[0038] 1) Preparation of sensitizer: 20 kg of sodium nitrite, 15 kg of zinc nitrate, and 15 kg of calcium nitrate were mixed and dissolved in 50 kg of water with a water temperature of 25° C. to obtain a sensitizer;

[0039] 2) Preparation of emulsification matrix: 30kg of sp-80 emulsifier, 5kg of polymer emulsifier and 65kg of composite wax are mixed to prepare an oil phase solution, 830kg of ammonium nitrate, 90kg of sodium nitrate and 80kg of water are mixed to obtain a crystallization point of the water phase of For the water phase solution at 89°C, take 935kg of the water phase solution and 65kg of the oil phase solution, and emulsify at 95°C to obtain an emulsification matrix, the temperature of the emulsification matrix is 60°C, and the density is 1.39g / cm 3 ;

[0040] 3) Preparation of emulsion explosive: Add the sensitizer to the emulsification mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com