Low-odor low-VOC thermoplastic plastic

A thermoplastic, low-odor technology, used in the field of automotive interior materials, can solve problems such as harming health, achieve strong adsorption performance, good compatibility, and solve the effect of harming human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

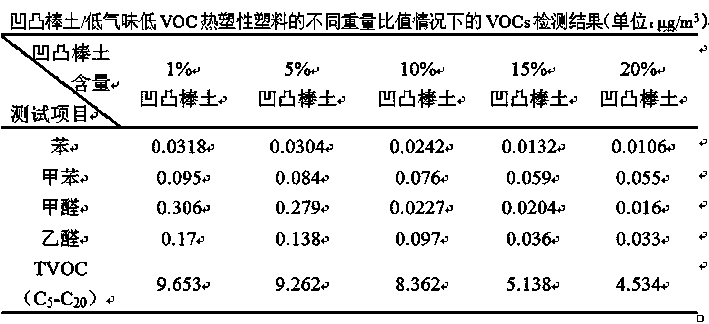

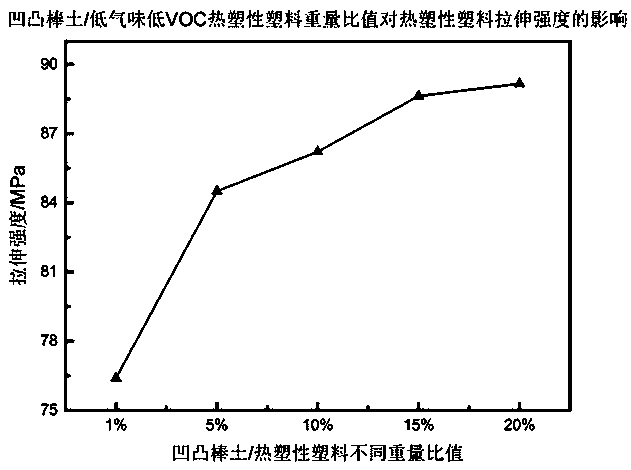

[0024] Example 1: A low-odor and low-VOC thermoplastic, comprising the following components in parts by weight, 40 parts of a polymer substrate, 1 part of an inorganic filler, and attapulgite is included in the inorganic filler; the polymer substrate is made of PE, Composed of one or more of PP, PET, PA6, PBT, PU, PVC, PS, PC, ABS, TPO; the inorganic filler is composed of one or more of bentonite, kaolin, activated carbon, calcium carbonate and attapulgite , the weight of attapulgite is 0.01% of the weight of inorganic filler.

Embodiment 2

[0025] Embodiment 2: A low-odor and low-VOC thermoplastic, including the following components in parts by weight, 65 parts of polymer substrates, 25 parts of inorganic fillers, and 10 parts of additives. Attapulgite is included in the inorganic fillers; The material is composed of PE, PP, PET; the inorganic filler is composed of bentonite, kaolin, and attapulgite, and the weight of attapulgite is 50% of the weight of the inorganic filler; attapulgite is modified attapulgite; additives include the following parts by weight Components, 5 parts of plasticizer, 3 parts of antioxidant, 2 parts of light stabilizer, 2 parts of ultraviolet absorber; plasticizer consists of dibutyl phthalate, dihexyl phthalate, epoxy hard One or more of butyl fatty acid, dioctyl adipate, and trichloroethyl phosphate; the antioxidant is composed of one of antioxidant 1010, antioxidant 168, antioxidant 1076, and antioxidant 1098 or multiple compositions; the light stabilizer is composed of one or more of...

Embodiment 3

[0029] Embodiment 3: A low-odor and low-VOC thermoplastic, including the following components in parts by weight, 90 parts of polymer substrates, 50 parts of inorganic fillers, and 20 parts of additives. Attapulgite is included in the inorganic fillers; The material is composed of PA6, PBT, PU, PVC; the inorganic filler is composed of activated carbon, calcium carbonate and attapulgite, and the weight of attapulgite is 80% of the weight of the inorganic filler; attapulgite is modified attapulgite; the additives include the following weight The number of parts includes 10 parts of plasticizer, 5 parts of antioxidant, 3 parts of light stabilizer, and 3 parts of ultraviolet absorber; the plasticizer is composed of dibutyl phthalate and dihexyl phthalate; The antioxidant is composed of antioxidant 1010 and antioxidant 168; the light stabilizer is light stabilizer HTP; the ultraviolet absorber is composed of UV~326 and UV327.

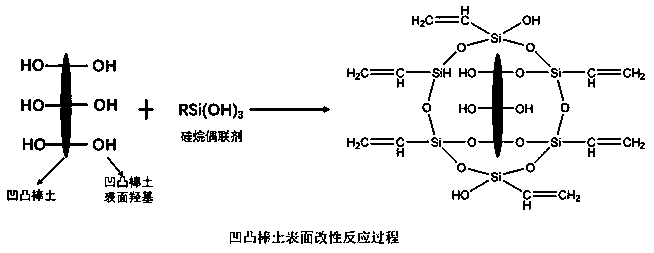

[0030] The modification method of modified attapulgi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com