Method for extracting grease from chlamydomonas

A technology for extracting oil and Chlamydomonas, applied in microorganism-based methods, fat oil/fat production, fat oil/fat refining, etc., to achieve the effect of good market application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

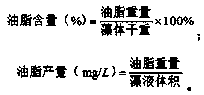

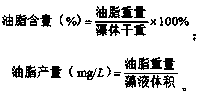

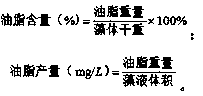

Image

Examples

Embodiment 1

[0022] A method for extracting oil from Chlamydomonas comprises the following steps:

[0023] Step 1: Cultivation of Chlamydomonas: Inoculate the activated fresh microalgae culture solution cultivated to the logarithmic growth phase into the Erlenmeyer flask containing freshly prepared microalgae medium according to the inoculum size of 10% (v / v) , wrap the mouth of the bottle with 4 layers of gauze, and place the Erlenmeyer flask in a light incubator for cultivation;

[0024] Step 2: Preparation of dry microalgae powder: measure the volume of the Chlamydomonas culture solution cultivated in Step 1, place it in a centrifuge tube and centrifuge for the first time to obtain the first Chlamydomonas algae sediment and the first supernatant, discard The first supernatant; wash the first Chlamydomonas algae precipitate with distilled water, perform a second centrifugation to obtain the second Chlamydomonas algae sediment and the second supernatant, and collect the second Chlamydomon...

Embodiment 2

[0036] A method for extracting oil from Chlamydomonas comprises the following steps:

[0037] Step 1: Cultivation of Chlamydomonas: Inoculate the activated fresh microalgae culture solution cultivated to the logarithmic growth phase into the Erlenmeyer flask containing freshly prepared microalgae medium according to the inoculum size of 10% (v / v) , wrap the mouth of the bottle with 4 layers of gauze, and place the Erlenmeyer flask in a light incubator for cultivation;

[0038] Step 2: Preparation of dry microalgae powder: measure the volume of the Chlamydomonas culture solution cultivated in Step 1, place it in a centrifuge tube and centrifuge for the first time to obtain the first Chlamydomonas algae sediment and the first supernatant, discard The first supernatant; wash the first Chlamydomonas algae precipitate with distilled water, perform a second centrifugation to obtain the second Chlamydomonas algae sediment and the second supernatant, and collect the second Chlamydomon...

Embodiment 3

[0050] A method for extracting oil from Chlamydomonas comprises the following steps:

[0051] Step 1: Cultivation of Chlamydomonas: Inoculate the activated fresh microalgae culture solution cultivated to the logarithmic growth phase into the Erlenmeyer flask containing freshly prepared microalgae medium according to the inoculum size of 10% (v / v) , wrap the mouth of the bottle with 4 layers of gauze, and place the Erlenmeyer flask in a light incubator for cultivation;

[0052] Step 2: Preparation of dry microalgae powder: measure the volume of the Chlamydomonas culture solution cultivated in Step 1, place it in a centrifuge tube and centrifuge for the first time to obtain the first Chlamydomonas algae sediment and the first supernatant, discard The first supernatant; wash the first Chlamydomonas algae precipitate with distilled water, perform a second centrifugation to obtain the second Chlamydomonas algae sediment and the second supernatant, and collect the second Chlamydomon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com