Heat pump system using evaporative cooling

An evaporative cooling, heat pump system technology, applied in heat pumps, air conditioning systems, household heating and other directions, can solve the problems of icing on the outer surface, the system can not run, the thermal resistance increases, etc., to achieve the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] The present invention is not limited to the specific embodiments described above, and it is not intended to limit the present invention. All technical solutions obtained by means of equivalent replacement or equivalent transformation fall within the protection scope of the present invention.

[0025] In the specification, it can be understood that when "first" and "second" refer to components, they are only used for the purpose of distinction, and do not limit the sequence or importance of the components. Similarly, "a", "b", "c", "d", etc. in the specification only represent different inlets or outlets of components, and do not represent their order.

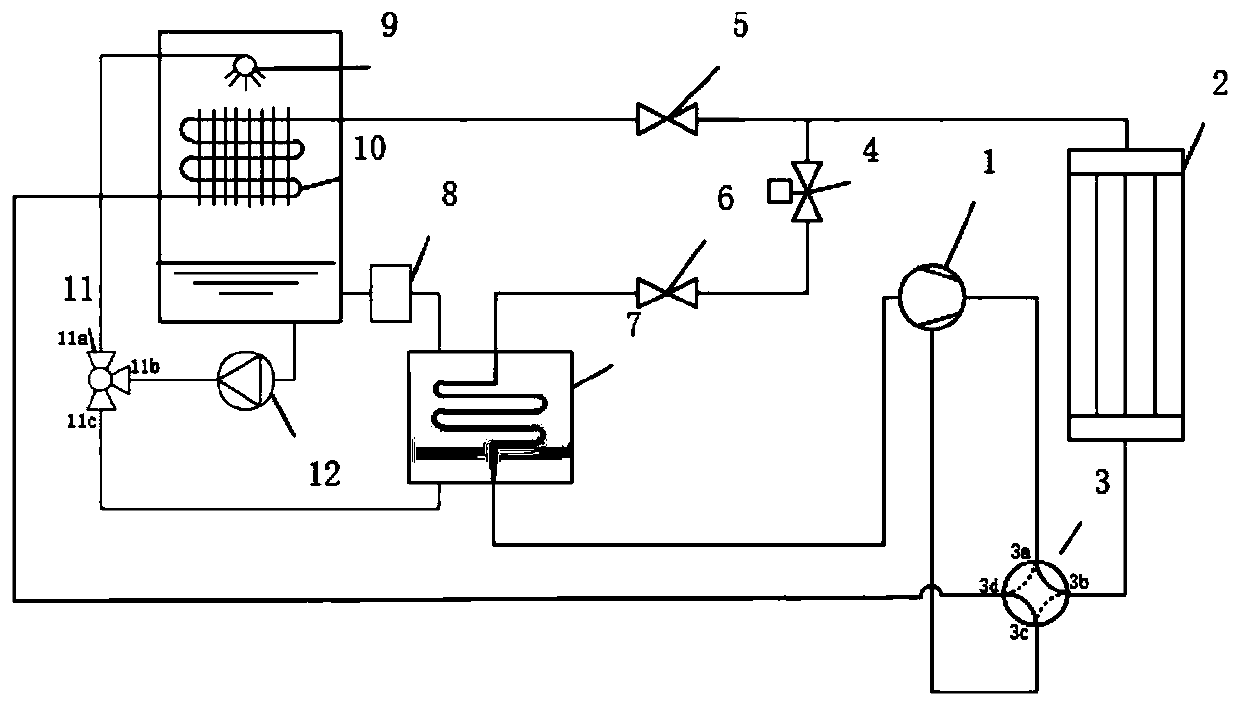

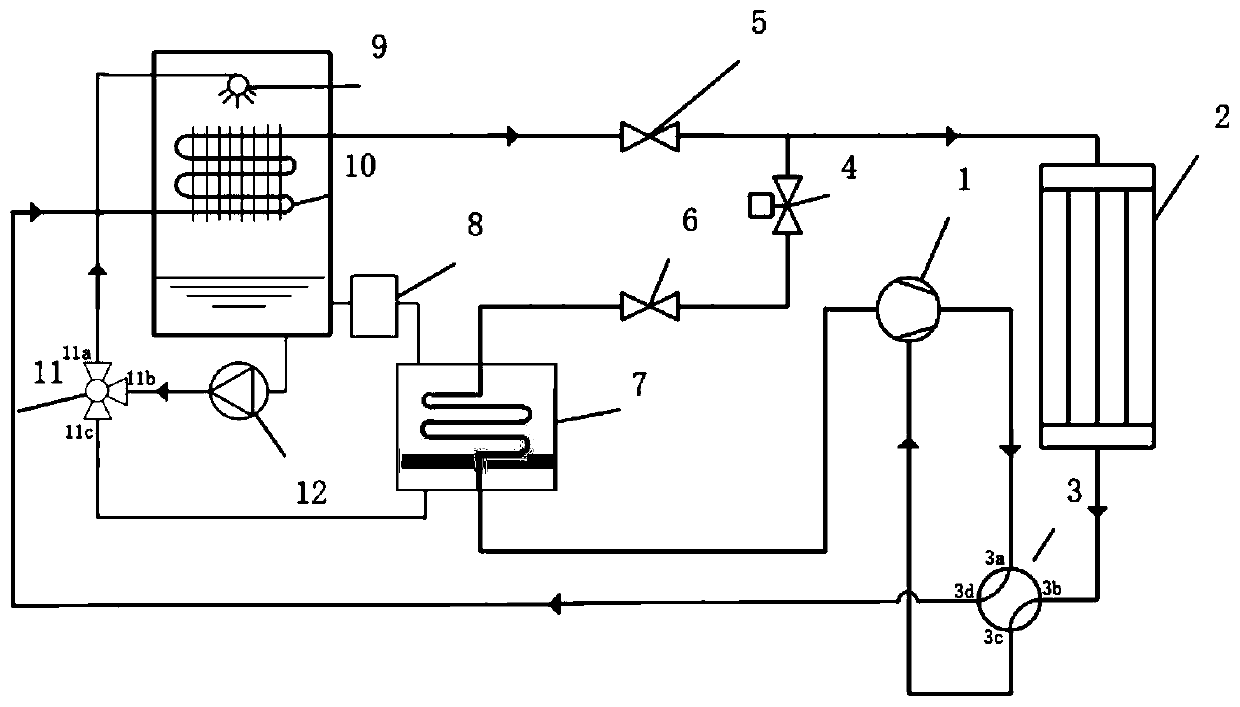

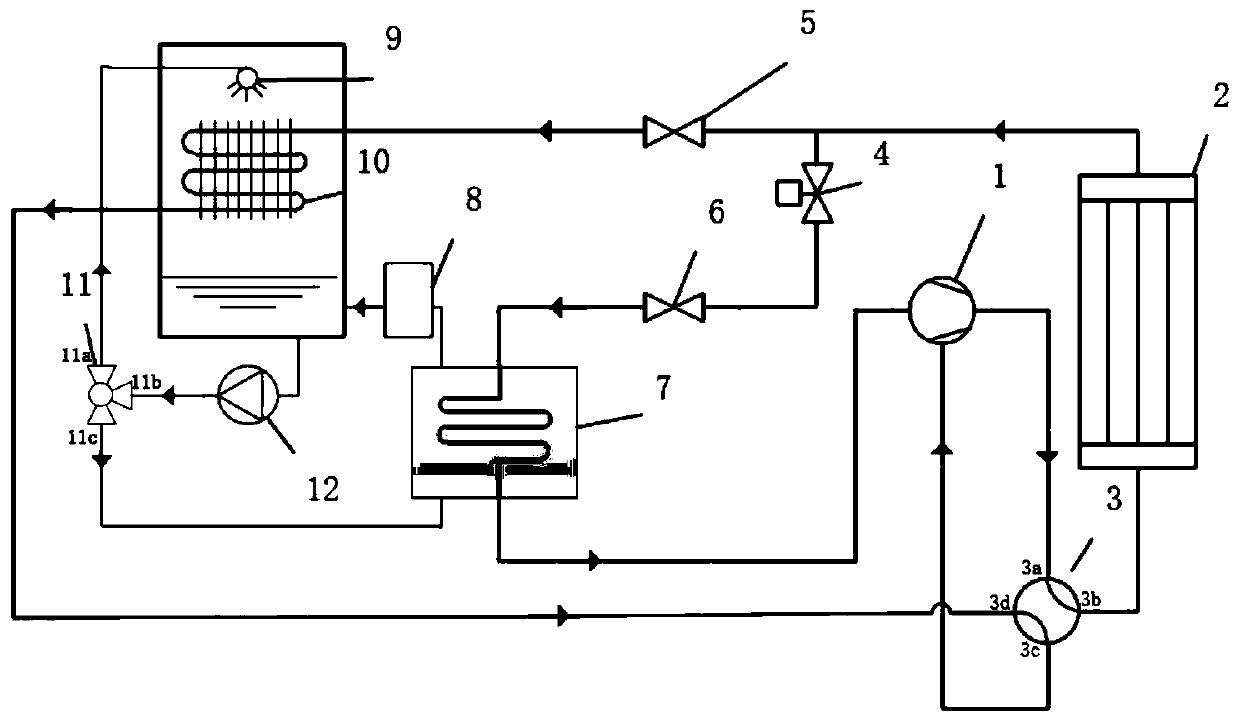

[0026] Such as figure 1 , the present invention comprises a compressor 1, an indoor heat exchanger 2, a four-way reversing valve 3, a solenoid valve 4, a first throttle valve 5, a second throttle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com