Quasi-telecentric high-power optical focusing lens for laser welding machine and imaging method of quasi-telecentric high-power optical focusing lens

An optical focusing lens, laser welding machine technology, applied in laser welding equipment, optics, condenser lens and other directions, can solve the problems of affecting welding quality and welding speed, affecting welding quality and precision, large lens energy loss, etc., to achieve energy concentration, The effect of increasing the entrance pupil diameter and relative aperture and improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

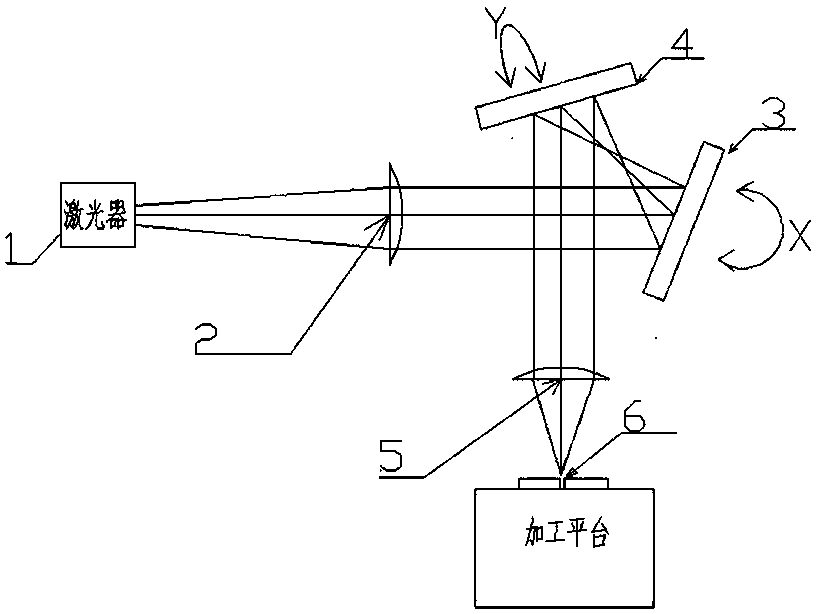

[0028] Embodiment 1: The technical solution of this embodiment is to provide an optical focusing lens and an imaging method thereof for a vibrating mirror laser welding machine. The focal length of the optical focusing lens is f=150mm, the F number F / #=6, the scanning angle θ=±15°, the working wavelength is 1.064μm, the aperture diaphragm is located at the focal plane of the lens, and the X scanning galvanometer to the Y scanning Galvanometer distance d x,y =21mm, the distance d from the Y scanning galvanometer to the front surface of the first lens according to the light incident direction y,1 =40mm.

[0029] See attached figure 1, which is the working principle diagram of the laser welding machine. After the beam expansion of the laser 1 passes through the collimation system 2, it enters the X galvanometer 3 for deflection of the light in the X direction, and then enters the Y galvanometer 4 for Y The light in the direction is deflected, and finally, the light is focused ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Entrance pupil diameter | aaaaa | aaaaa |

| Field of view | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com