Shallow trench isolation structure and preparation method thereof

A technology of isolation structures and shallow trenches, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as side trenches, reduce parasitic currents, avoid formation of side trenches, and improve production yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

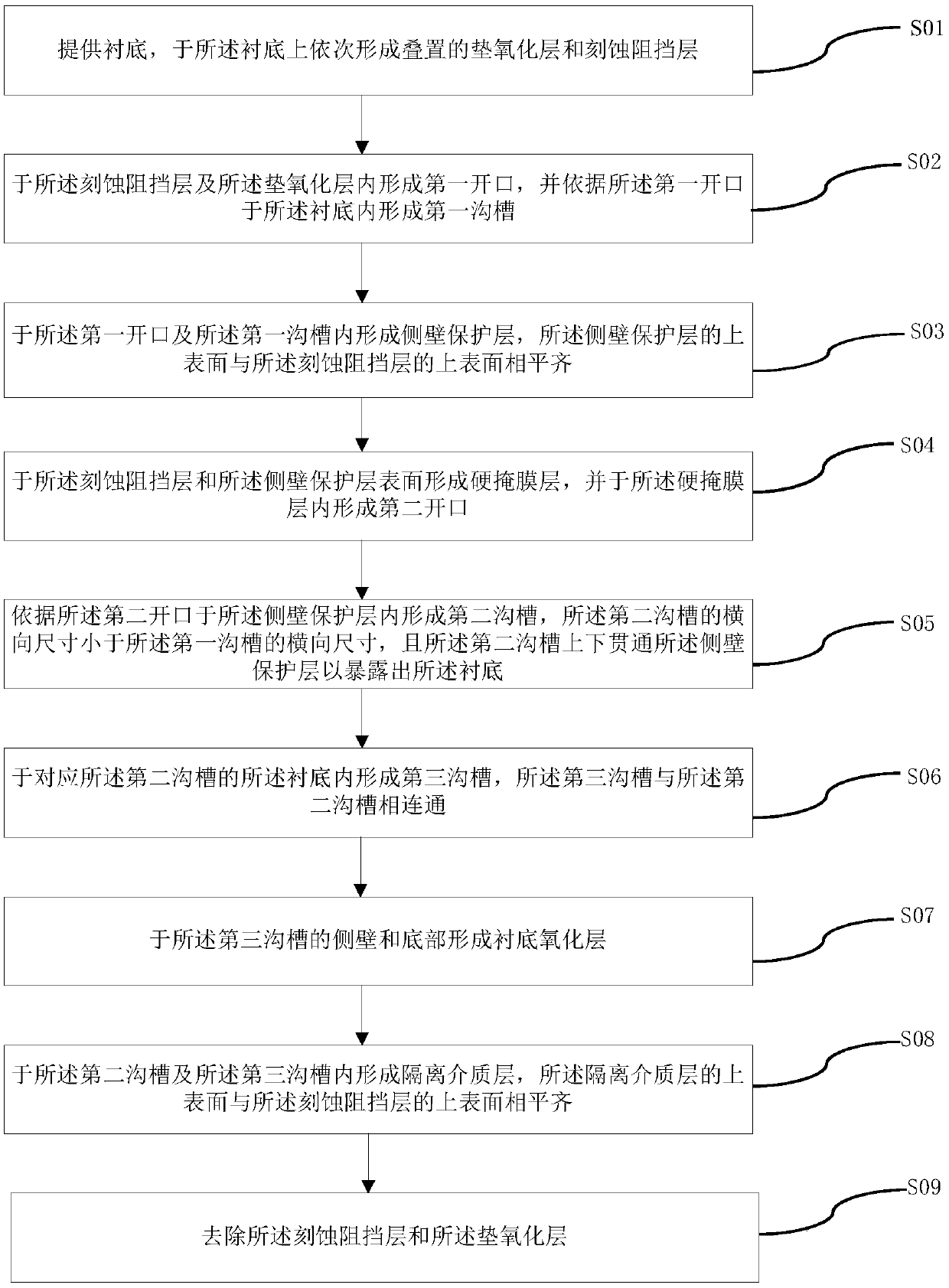

[0069] Such as Figure 2 to Figure 17 As shown, the present invention provides a method for preparing a shallow trench isolation structure, the method comprising the following steps:

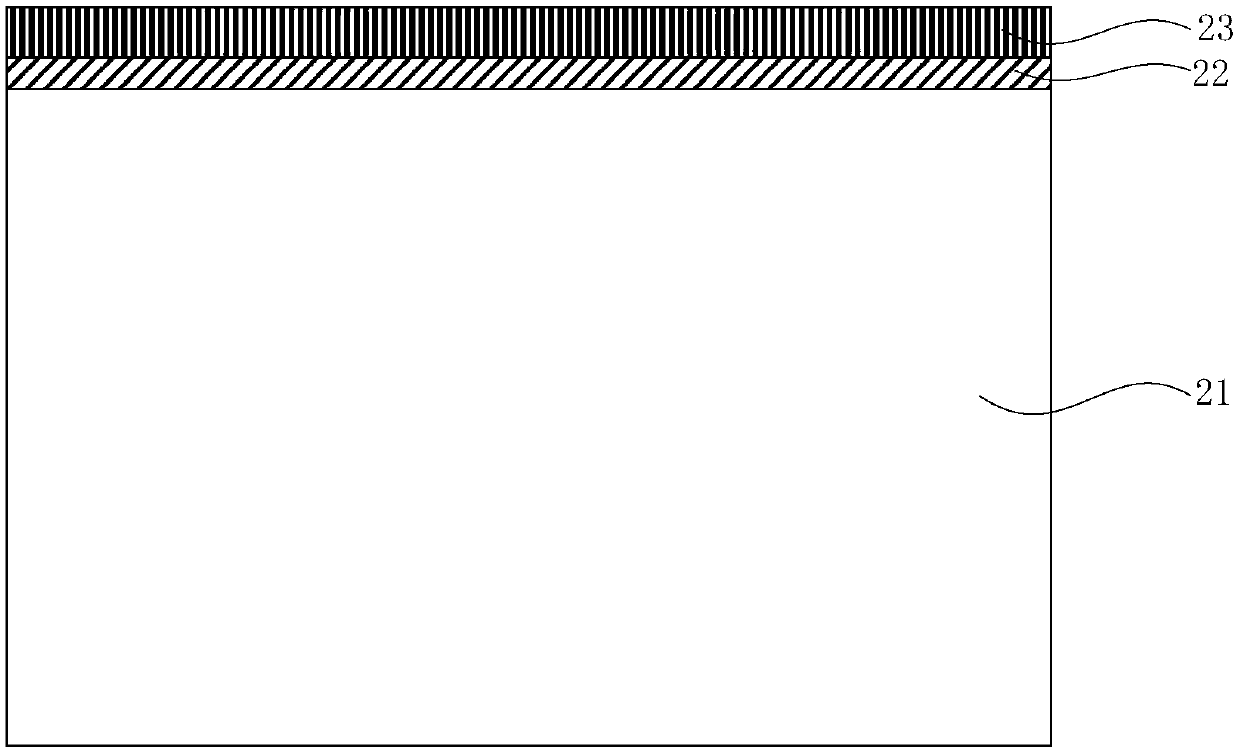

[0070] 1) providing a substrate, and sequentially forming a stacked pad oxide layer and an etching stopper layer on the substrate;

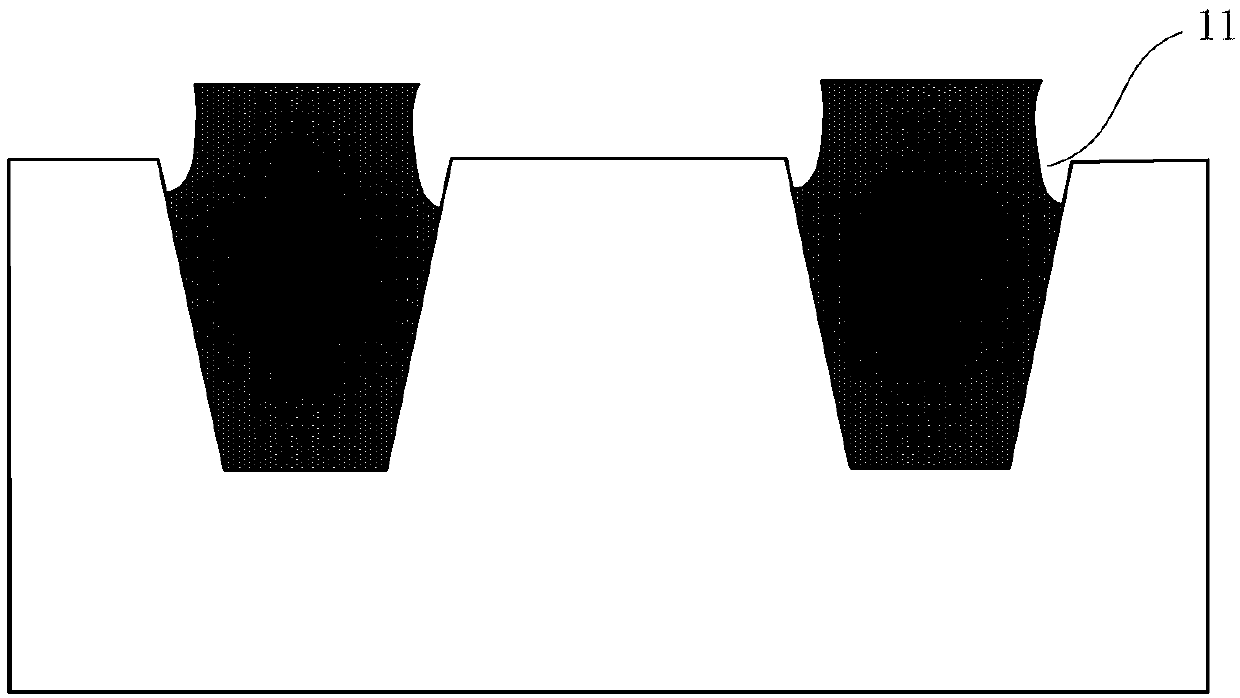

[0071] 2) forming a first opening in the etch stop layer and the pad oxide layer, and forming a first trench in the substrate according to the first opening;

[0072] 3) forming a sidewall protection layer in the first opening and the first trench, the upper surface of the sidewall protection layer being flush with the upper surface of the etching stopper layer;

[0073] 4) forming a hard mask layer on the surface of the etching stopper layer and the sidewall protection layer, and forming a second opening in the hard mask layer;

[0074] 5) forming a second groove in the sidewall protection layer according to the second opening, the lateral dimension of the secon...

Embodiment 2

[0099] Such as Figure 17 As shown, the present invention also provides a shallow trench isolation structure, which is obtained by the preparation method described in the first embodiment. Specifically, the shallow trench isolation structure of this embodiment includes:

[0100] Substrate 21;

[0101] The first groove 24 is located in the substrate 21;

[0102] a sidewall protection layer 25, located on the sidewall of the first trench 24, and extending from the bottom of the first trench 24 to above the substrate 21;

[0103] The second groove 27 is partly located in the substrate 21 and inside the sidewall protection layer 25 , the upper surface of the second groove 27 is flat with the upper surface of the sidewall protection layer 25 together;

[0104] The third trench 28 is located in the substrate 21 and at the bottom of the second trench 27, and communicates with the second trench 27;

[0105] a substrate oxide layer 29 located on the sidewall and bottom of the thir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com