Oil-cooled high-voltage brushless direct-current motor for aviation fuel system

A DC motor and aviation fuel technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of low efficiency, heavy weight, and low electromagnetic density of asynchronous motors, and achieve good heat resistance of aviation fuel, heat dissipation and cooling effect Good, the effect of reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

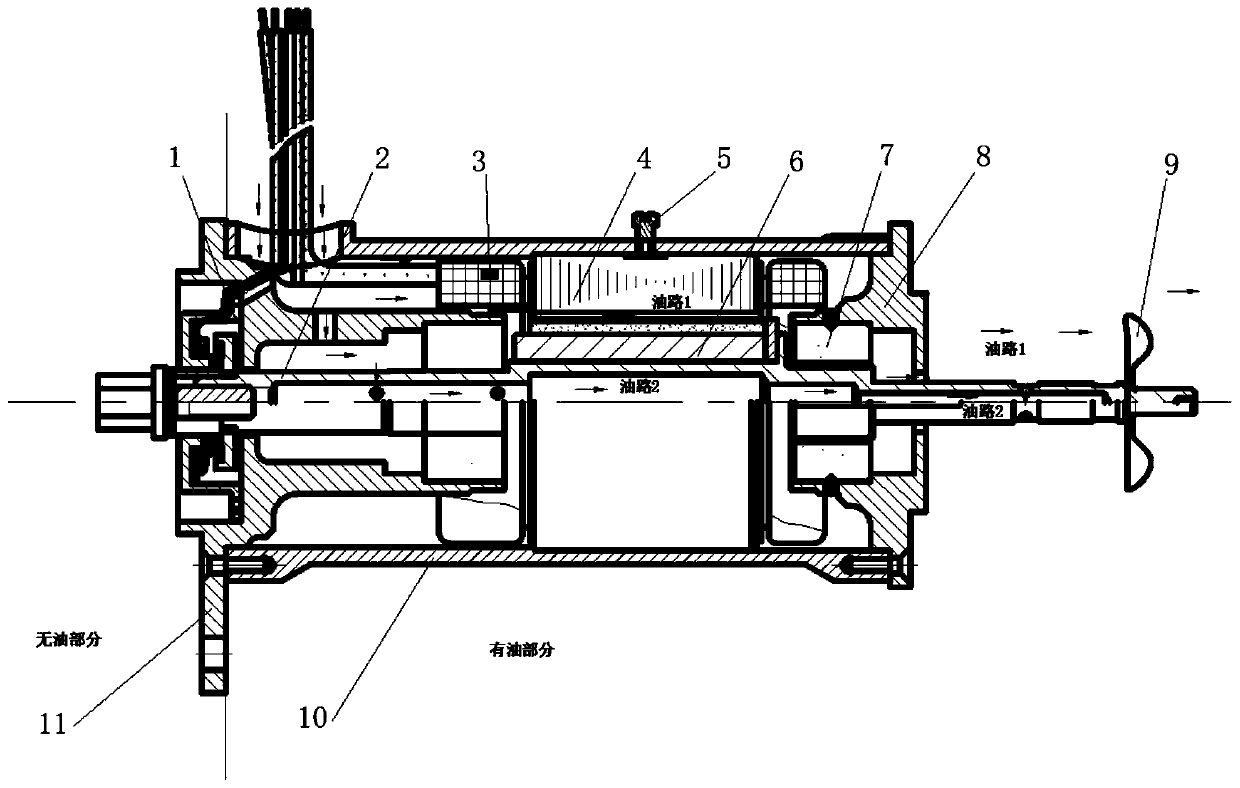

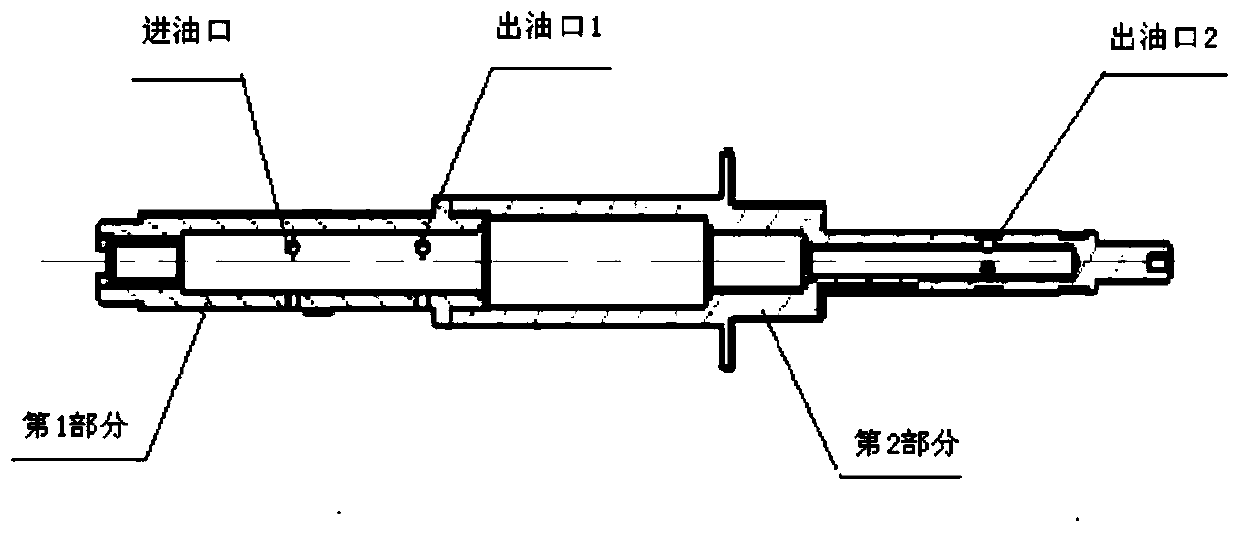

[0050] Such asfigure 1 As shown, an oil-cooled aviation high-voltage brushless DC motor involved in this embodiment. The motor is mainly composed of Hall sensor assembly 1 for back-up starting, composite shaft 2 with pressurization and cooling functions, thermistor 3 for detecting winding temperature, stator assembly 4, stator positioning screw 5, rotor assembly 6, Graphite bearing 7 (both ends), shaft extension end cover assembly 8, booster impeller 9, casing 10 and non-shaft extension end cover assembly 11 with flange function are composed of components. The left side of the non-shaft extension end face of the motor is a part without fuel, and the rest is a part with fuel.

[0051] The specific assembly relationship of the motor is as follows: the stator as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com