One-step formed hollow fiber nanofiltration membrane filament and preparation method thereof

A nanofiltration membrane and hollow technology, which is applied to the field of one-step forming hollow fiber nanofiltration membrane and its preparation, can solve the problems of large pore size and low pollution resistance, and achieves small pore size, strong pollution resistance, and good pollution resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

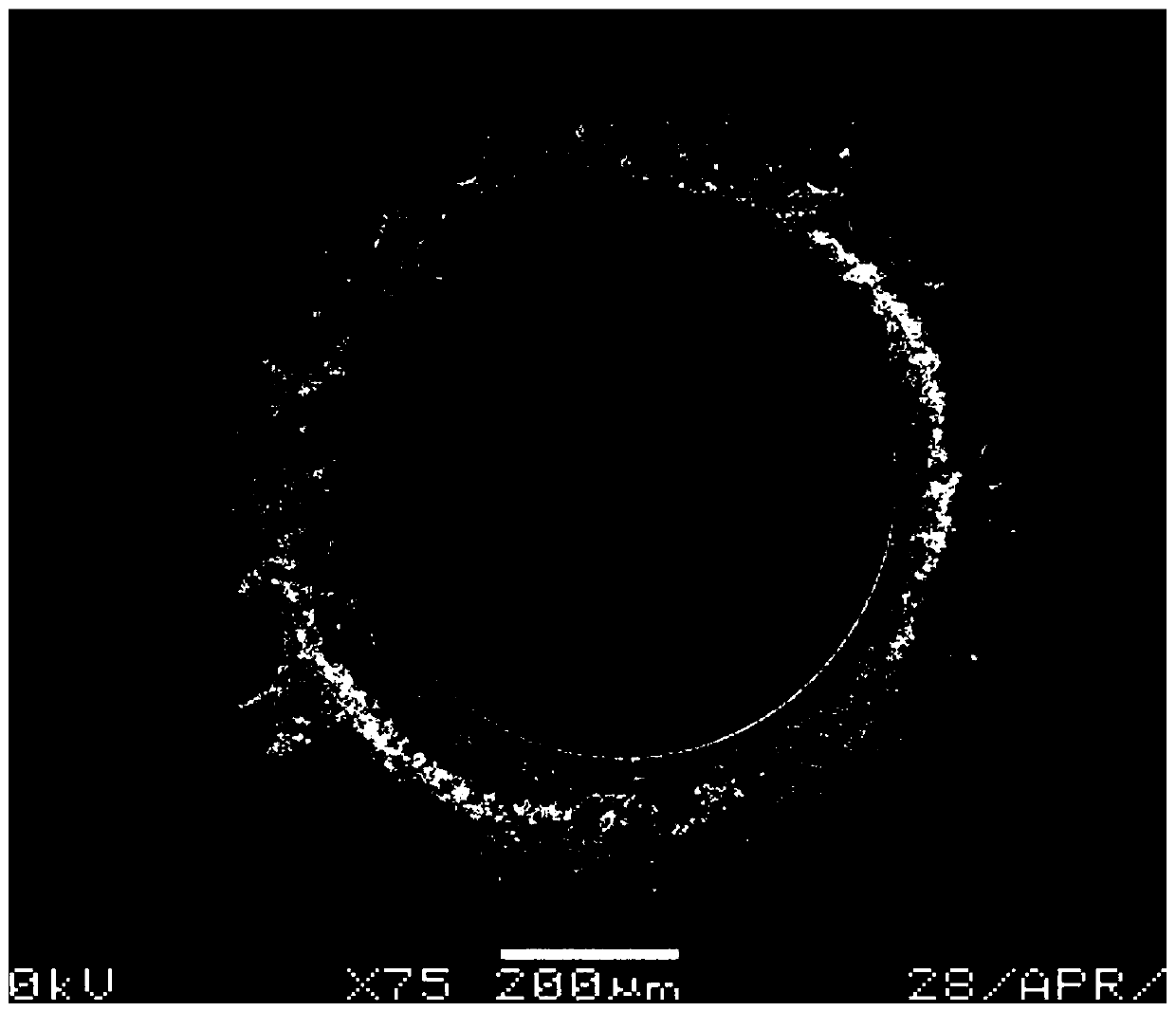

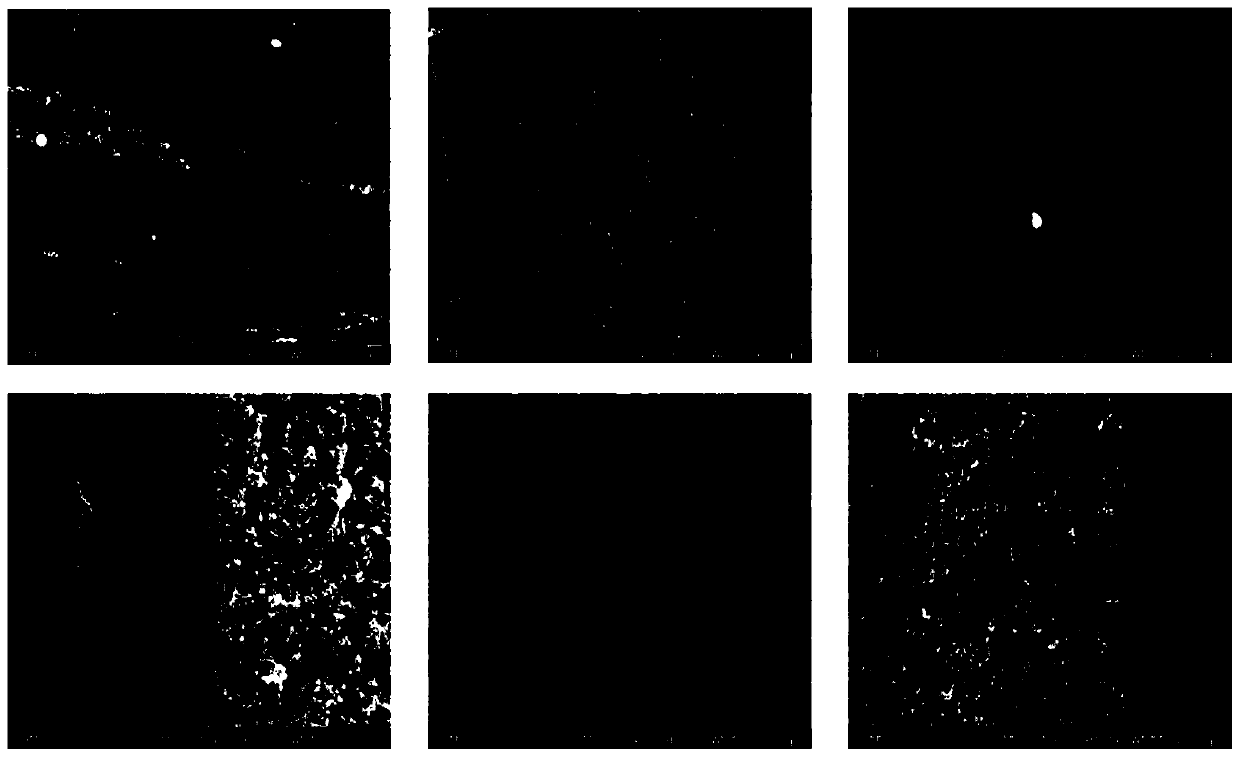

[0032] In this scheme, a one-step hollow fiber nanofiltration membrane filament is prepared with the following parameters.

[0033] Membrane case one:

[0034] A one-step forming hollow fiber nanofiltration membrane filament, the membrane making system includes feed liquid and core liquid.

[0035] The feed liquid is prepared by mixing and dissolving hydrophilic polymers, solvents, non-solvents and feed liquid additives, and then undergoes vacuum defoaming treatment.

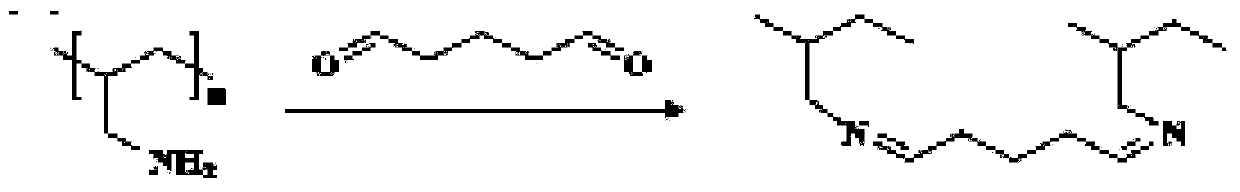

[0036] The core fluid is prepared by mixing and dissolving corresponding solvents, non-solvents and core fluid additives. The hydrophilic polymers are polyethersulfone and sulfonated polyethersulfone. The solvent is dimethylacetamide, the non-solvent is polyethylene glycol 400, the feed liquid auxiliary agent is polyethyleneimine, and the core liquid auxiliary agent is glutaraldehyde.

[0037] According to the weight ratio, take 25 parts of hydrophilic polymers, 18.5 parts of non-solvents, 54.5 parts of solve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com