Plastic deformation method for grain refinement and twin crystal material preparation device

A technology for plastic deformation and grain refinement, which is applied in the field of material processing and can solve problems such as hindering the development of plastic deformation technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

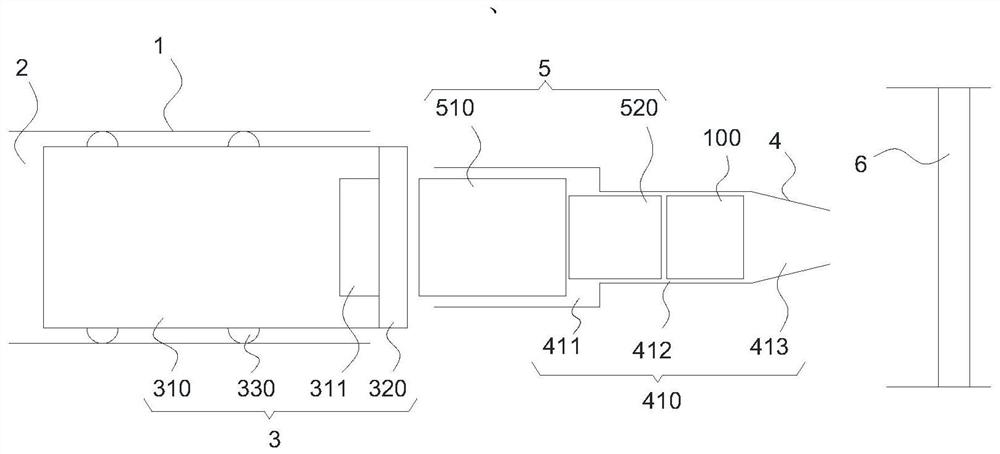

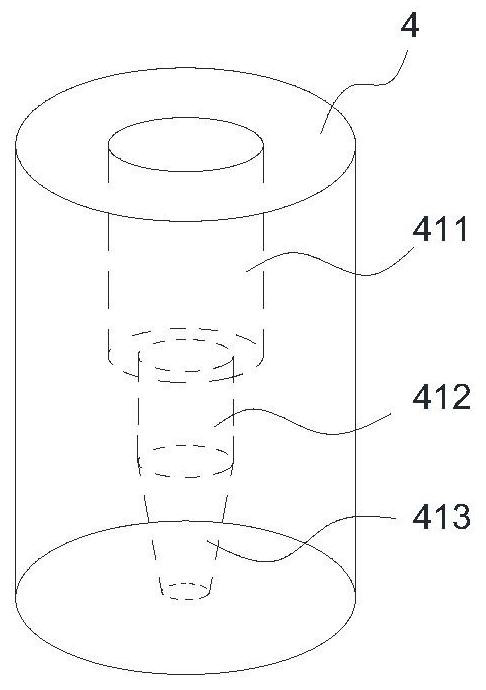

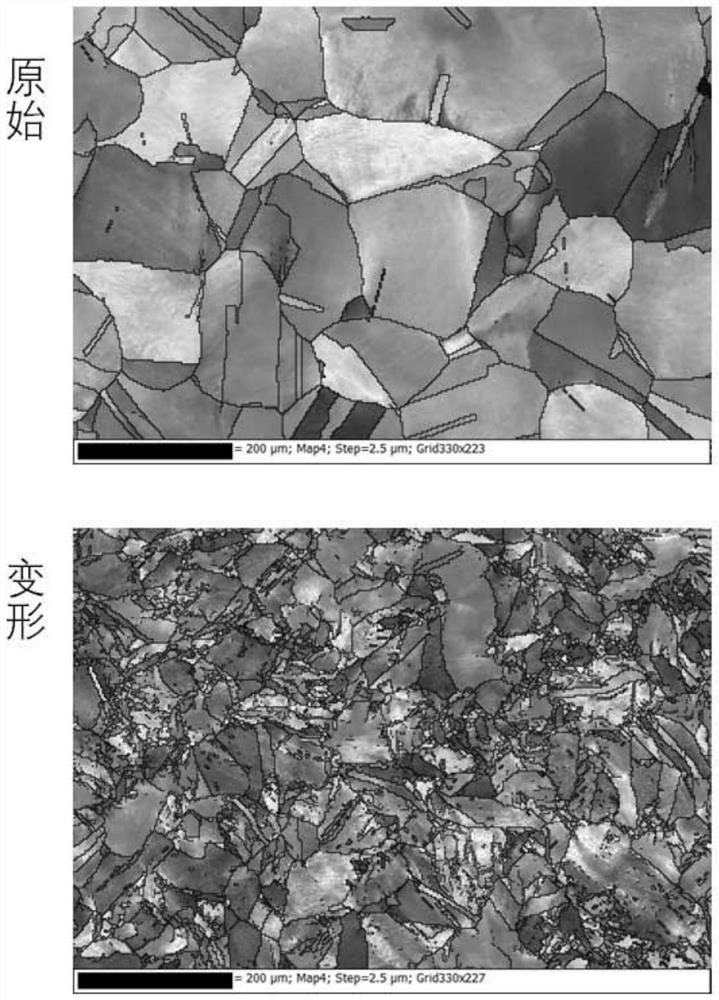

[0050] Cut the rolled pure copper plate into a cylindrical bar with a diameter of 8mm and a length of 12-14mm along the ND, apply MoS2 lubricant on the surface and place it in the initial sample 100 slot of the mold 4, and then push the material The front part of the part 5 is the collimating rod 520 and the rear part is the punching rod 510, which is installed on the mold 4, so that the material pushes the front part and the rear part of the part 5 into the channel 410 of the mold 4; use nitrogen or argon (7-10MPa ) accelerates the bullet 3, and the exit speed of the muzzle projectile is 230m / s as measured by the magnetic velocity measuring device. If the air pressure is too small (less than 7MPa) during the impact process, the sample 100 cannot be completely extruded from the mold 4. Cross-sectional channel, if the air pressure charged is too high (higher than 10MPa), the kinetic energy of the impact is too large. After the appropriate air pressure is charged, the punch 510 w...

Embodiment 2

[0053] Cut the rolled-formed pure nickel plate into a cylindrical bar with a diameter of 8mm and a length of 12-14mm along the ND, apply MoS2 lubricant on the surface and place it in the channel 410 of the initial cylinder of the mold 4, and then align the Rod 520 and punch rod 510 are installed on the mold 4, make material pushing part 5 insert channel 410; Use nitrogen or argon gas (7-10MPa) to bullet 3 acceleration, the muzzle projectile speed of measuring through magnetic velocity measuring device is 190m / s, if the air pressure charged during the impact process is too small, the sample 100 cannot be completely extruded from the variable-section channel of the mold 4; Finally, the punch 510 of the material pushing part 5 squeezes the pure nickel sample 100 at high speed after being hit by the bullet 3 , and the pure nickel undergoes dynamic and severe plastic deformation when passing through the channel with variable cross-section, and finally the deformed sample 100 is obt...

Embodiment 3

[0056] Cut the rolled-formed pure aluminum plate into a cylindrical bar with a diameter of 8 mm and a length of 12-14 mm along the ND, apply MoS2 lubricant on the surface and place it in the channel 410 of the mold 4, and then place the collimation rod 520 And the punch rod 510 is installed on the mold 4, the front and the rear of the material pushing part 5 are inserted into the channel 410; use nitrogen or argon (7-10MPa) to accelerate the bullet 3, record the muzzle projectile through the magnetic velocity measuring device The speed is 190m / s. If the air pressure charged during the impact process is too small, the sample 100 cannot be completely extruded from the variable-section channel 410 of the mold 4. If the air pressure charged is too high, the kinetic energy of the impact is too large. After being filled with a suitable air pressure, the punch 510 of the material pushing part 5 extrudes the pure aluminum sample 100 at a high speed after being hit by the bullet 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com