Extraction and separation method of glabridin

A technology of glabridin and a separation method, which is applied in the field of separation and purification, can solve the problems of silica gel reuse, unfriendly environment, and difficult cost control, and achieve the effects of low cost, solvent saving, and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

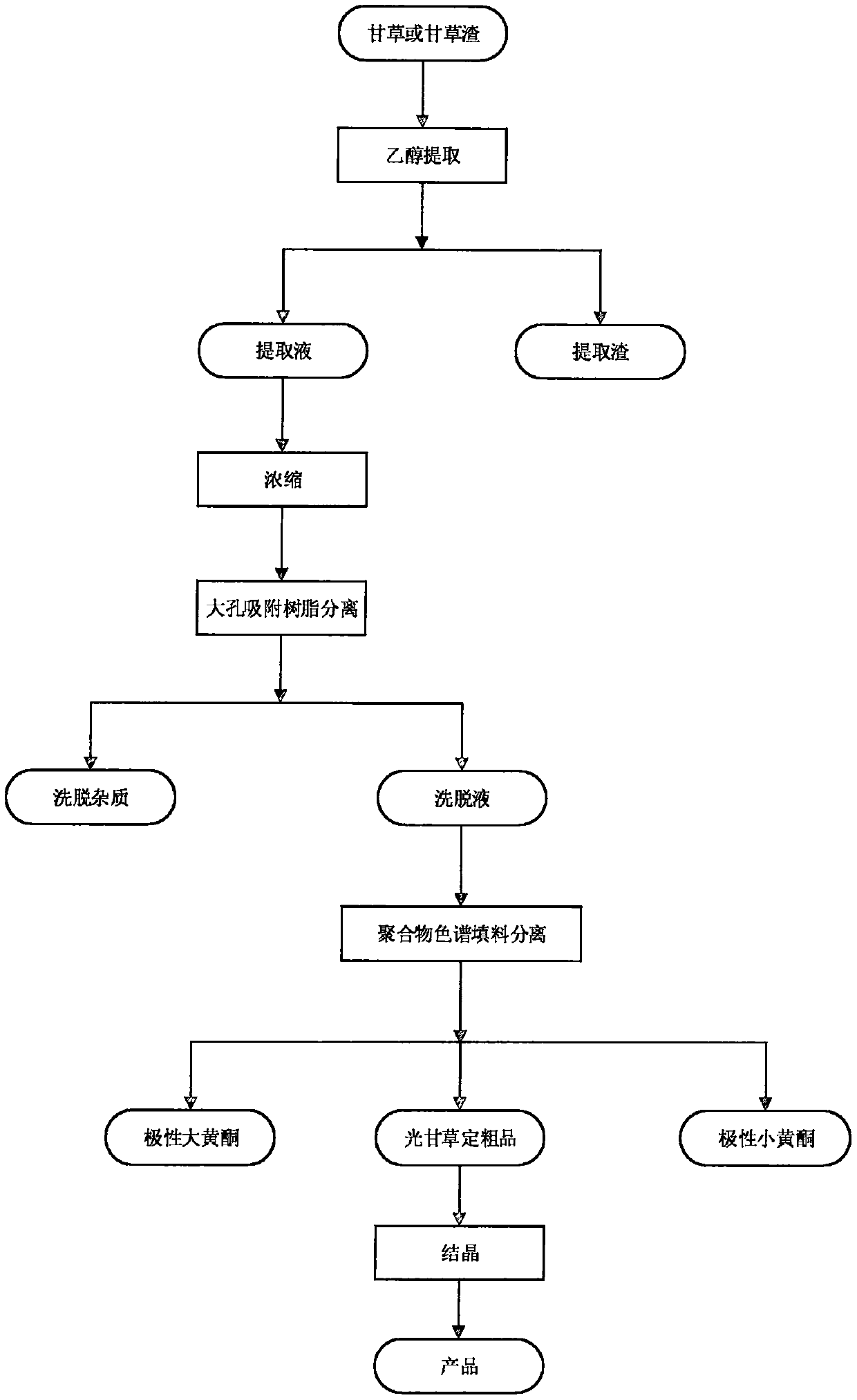

[0028]A method for extracting and separating high-purity glabridin from licorice residue by using a single solvent, using licorice residue as raw material, using ethanol for normal temperature sleeve extraction, coarse separation of macroporous adsorption resin, fine separation of polymer chromatography filler, and crystallization of ethanol According to the technological process, more than 95% of the glabridin product can be obtained at last.

[0029] (1) extraction

[0030] Take 30kg of dried licorice residue and put it into a 500L stainless steel extraction tank for the first extraction, add 210L of 90% ethanol, soak for 3 hours, and cycle for 5 minutes every 30 minutes. After the first extraction, separate the first extraction solution, the residue Then use 210L of 90% ethanol for the second extraction, soak at room temperature for 3 hours, and beat for 5 minutes every 30 minutes. Separate the extracting solution for the second time and use it for the next extraction. The...

Embodiment 2

[0038] (1) extraction

[0039] Take 30kg of dried licorice raw material and put it into a 500L stainless steel extraction tank for the first extraction, add 210L 80% ethanol, soak for 3hrs, and cycle for 5min every 30min. Use 210L of 80% ethanol for the second extraction, soak at room temperature for 3 hours, and beat for 5 minutes every 30 minutes. Separate the extracting solution for the second time and use it for the next extraction. The extracting solution for the second time is added to 30 kg of new licorice dregs to extract for the first time, and the extraction method is the same as above. 186L of separated cap extract solution enters the concentration process. Concentrate to 1 / 7 of the original volume, about 26L, adjust the ethanol concentration of the concentrated solution to 50%, and obtain 30L liquid, which is to be loaded on a macroporous adsorption resin ADS-17 column.

[0040] (2) Macroporous adsorption resin adsorption

[0041] 30L of concentrated solution is...

Embodiment 3

[0047] (1) extraction

[0048] Take 30 kg of dried licorice residue raw material and put it into a 500L stainless steel extraction tank for the first extraction, add 210L of 70% ethanol, soak for 3 hours, and cycle for 5 minutes every 30 minutes. Use 210L of 70% ethanol for the second extraction, soak at room temperature for 3 hours, and beat for 5 minutes every 30 minutes. Separate the extracting solution for the second time and use it for the next extraction. The extracting solution for the second time is added to 30 kg of new licorice dregs to extract for the first time, and the extraction method is the same as above. 185L of the separated cap extract liquid enters the concentration process. Concentrate to 1 / 7 of the original volume, about 26L, adjust the ethanol concentration of the concentrated solution to 50%, to obtain 30L liquid, to be loaded on a macroporous adsorption resin D101 column.

[0049] (2) Macroporous adsorption resin adsorption

[0050] 30L concentrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com