Glass dustproof coating composition, dustproof coating dispersion liquid and product containing dustproof coating

A technology of coating composition and dispersion liquid, which is applied in coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problems of limited application range, reduced visible light projection rate, and few commercial applications. To achieve the effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

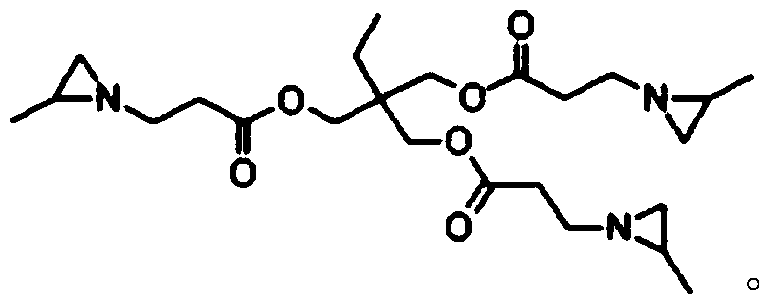

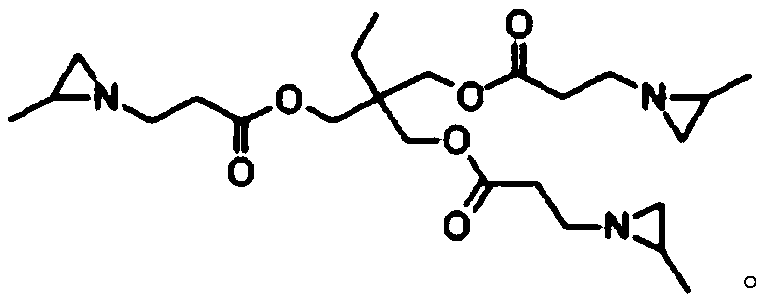

[0071] Add 7.1g U9160 polyurethane emulsion, 5g Nalco 1050 silicon dioxide aqueous dispersion, 188g deionized water and 0.1g CX-100 polyfunctional aziridine cross-linking agent in the glass bottle of 250ml, stir 30 minutes, obtain the solid content of 5% coating solution.

Embodiment 2

[0073] Add 4.3g U9160 polyurethane emulsion, 7g Nalco 1050 silica aqueous dispersion, 189g deionized water and 0.06g CX-100 polyfunctional aziridine crosslinking agent in the glass bottle of 250ml, stir 30 minutes, obtain solid content as 5% coating solution.

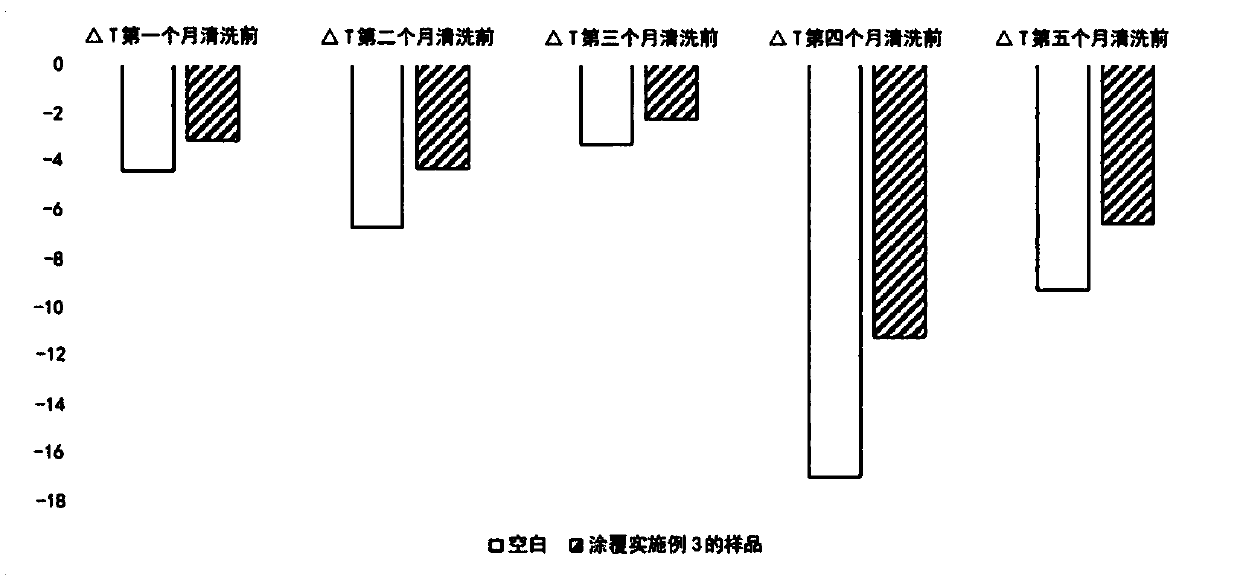

Embodiment 3

[0075]Add 14.5g U9160 polyurethane emulsion, 22.4g Nalco 1050 silica aqueous dispersion, 14.5g LSS-75 lithium silicate aqueous solution, 946.3g deionized water and 0.64g CX-100 polyfunctional aziridine to a 2000ml glass bottle crosslinking agent, and stirred for 30 minutes to obtain a coating solution with a solid content of 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap