Graphene modified epoxy resin adhesive and preparation method thereof

A technology of epoxy resin glue and graphene modification, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., and can solve problems that affect the use effect and life, affect the sealing performance of pipelines or equipment, and damage, etc. Reach the effect of reducing downtime repair time, easy production and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A graphene-modified epoxy resin glue is composed of two parts, A component and B component. The parts by mass of component A and component B are as follows:

[0034] Component A 100

[0035] Component B 30;

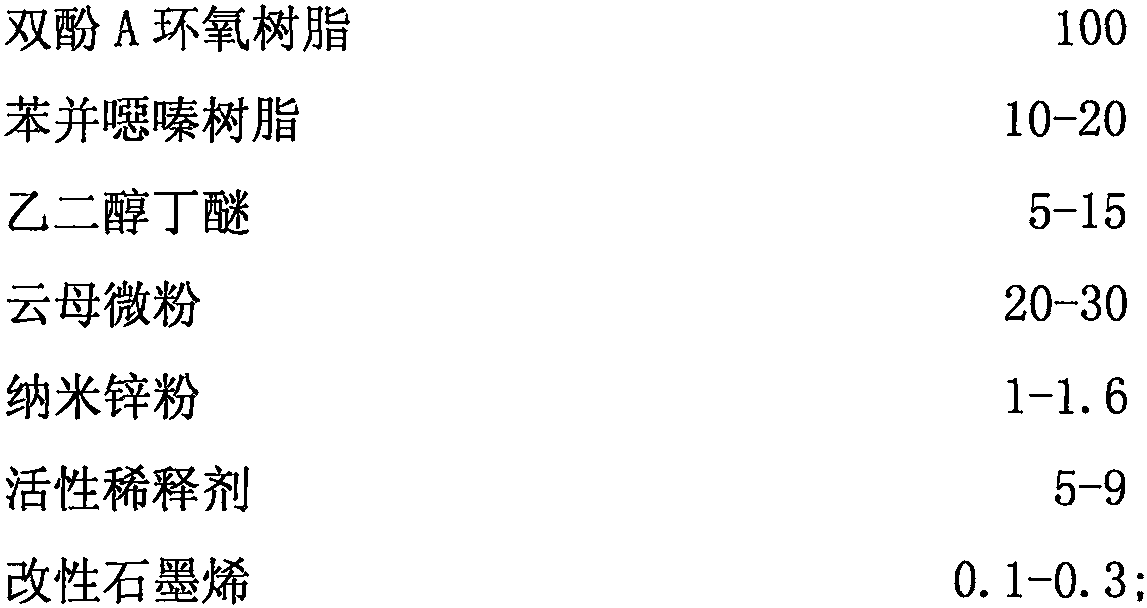

[0036] Component A consists of the following parts by mass:

[0037]

[0038] Part B is a modified epoxy curing agent, consisting of the following parts by mass:

[0039] Diethylenetriamine 100

[0040] Mannich base curing agent 10.

[0041] The Mannich base curing agent is prepared from p-nonylphenol, triethylenetetramine and formaldehyde in a molar ratio of 1:3:0.5.

[0042] A kind of preparation method of graphene modified epoxy resin glue, its preparation process is:

[0043] (1) Component A:

[0044] ① Weigh each component according to the following parts by mass:

[0045]

[0046] Disperse graphene oxide in N,N-dimethylformamide and stir evenly to form a graphene oxide dispersion; after raising the temperature of the dispersion to 150°C, add N-m...

Embodiment 2

[0055] A graphene-modified epoxy resin glue is composed of two parts, A component and B component. The parts by mass of component A and component B are as follows:

[0056] Component A 100

[0057] Component B 25;

[0058] Component A consists of the following parts by mass:

[0059]

[0060] Part B is a modified epoxy curing agent, consisting of the following parts by mass:

[0061] Diethylenetriamine 100

[0062] Mannich base curing agent 5.

[0063] The Mannich base curing agent is prepared from p-nonylphenol, triethylenetetramine and formaldehyde in a molar ratio of 1:2:0.4.

[0064] A kind of preparation method of graphene modified epoxy resin glue, its preparation process is:

[0065] (1) Component A:

[0066] ① Weigh each component according to the following parts by mass:

[0067]

[0068] Disperse graphene oxide in N,N-dimethylformamide and stir evenly to form a graphene oxide dispersion; after raising the temperature of the dispersion to 140°C, add N-me...

Embodiment 3

[0077] A graphene-modified epoxy resin glue is composed of two parts, A component and B component. The parts by mass of component A and component B are as follows:

[0078] Component A 100

[0079] Component B 35;

[0080] Component A consists of the following parts by mass:

[0081]

[0082] Part B is a modified epoxy curing agent, consisting of the following parts by mass:

[0083] Diethylenetriamine 100

[0084] Mannich base curing agent 15.

[0085] The Mannich base curing agent is prepared from p-nonylphenol, triethylenetetramine and formaldehyde in a molar ratio of 1:4:0.6.

[0086] A kind of preparation method of graphene modified epoxy resin glue, its preparation process is:

[0087] (1) Component A:

[0088] ① Weigh each component according to the following parts by mass:

[0089]

[0090] Disperse graphene oxide in N,N-dimethylformamide and stir evenly to form a graphene oxide dispersion; after raising the temperature of the dispersion to 160°C, add N-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com