Welding manufacturing method of large-scale cast-welded structure hoop cable clamp

A technology of casting welding structure and manufacturing method, which is applied to manufacturing tools, welding equipment, welding accessories, etc., can solve the problems of affecting casting quality and production period, reducing the casting yield of ring cable clips, increasing casting costs, etc., to ensure welding Mechanical properties, saving construction time and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

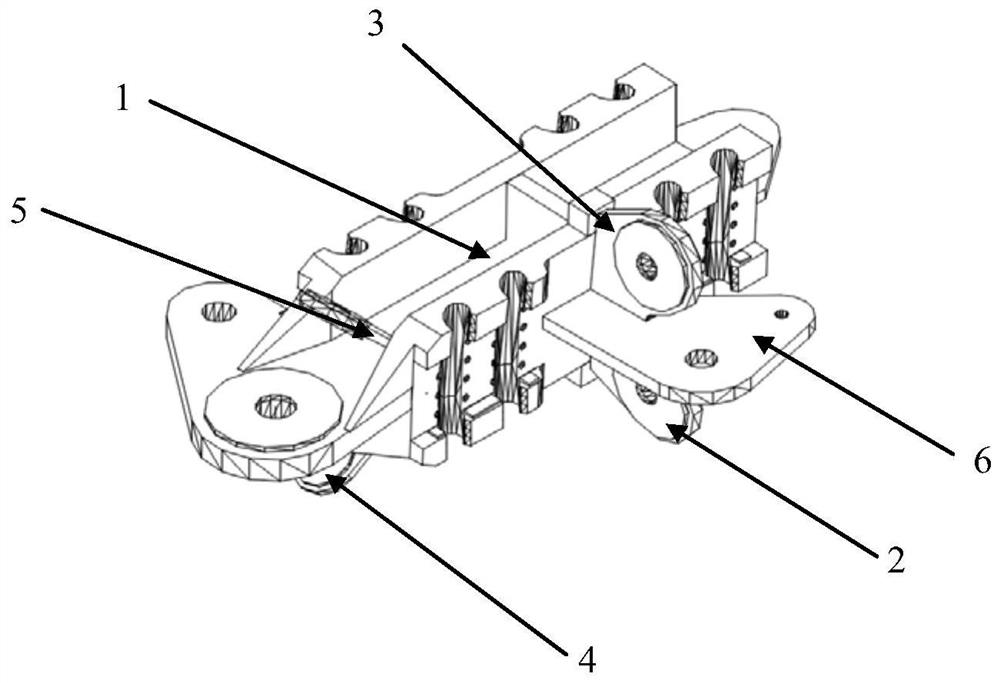

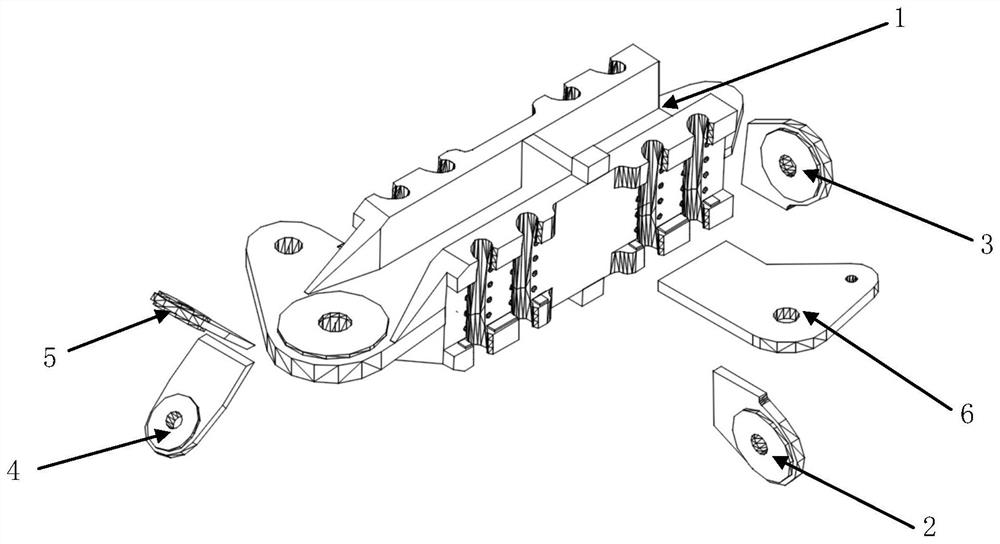

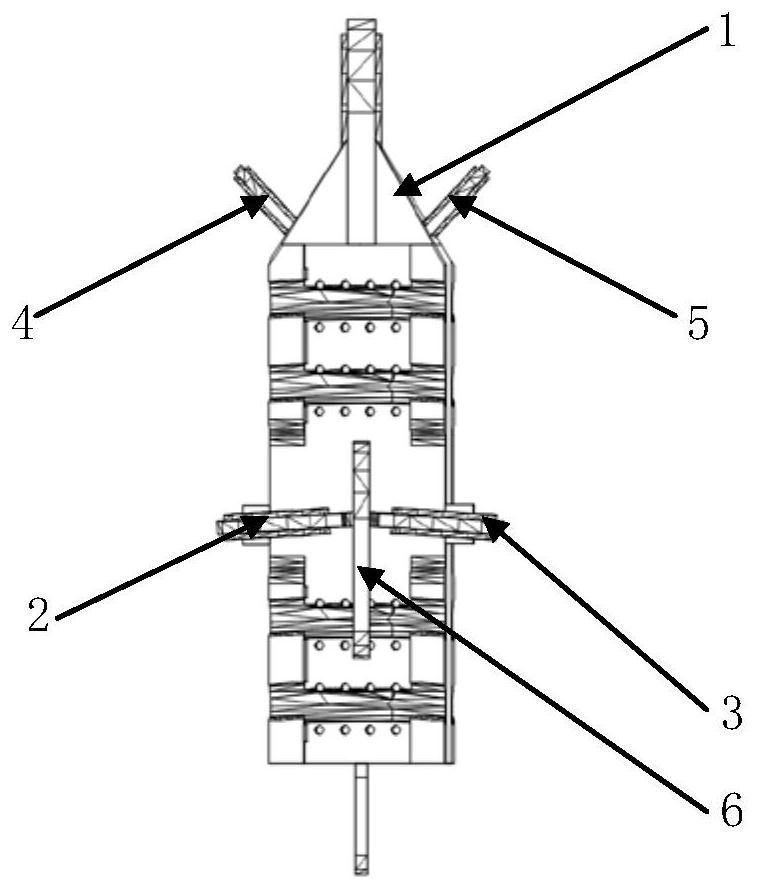

[0026] combine figure 1 , 3 The structure of the hoop cable clip shown in , 4 is identical to the structure of the hoop rope clip of the prior art, but the manufacturing method is different, and the hoop rope clip of the prior art adopts integral casting, figure 1 , 3 , The ring cable clip shown in 4 adopts the manufacturing method of casting and welding, as figure 2 Each lug is welded to the eyelet clip body as shown.

[0027] Such as figure 1 As shown, the welding manufacturing method of the large-scale cast-welded structure ring cable clip of the present invention comprises the following steps:

[0028] Step 1: After casting the ring cable clip body 1, polish the area to be welded so that the metal luster leaks out of the area to be welded, and use ultrasonic testing and magnetic particle testing to inspect the internal and surface quality of the area to be welded respectively to ensure that the area to be welded will not affect the welding After the quality defect is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com