Modified graphene oxide as well as preparation method and application thereof

A technology of oxidized stone and graphene, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as single effect, increase displacement fluid viscosity, cumbersome process, etc., achieve high reaction rate, improve oil displacement Good efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

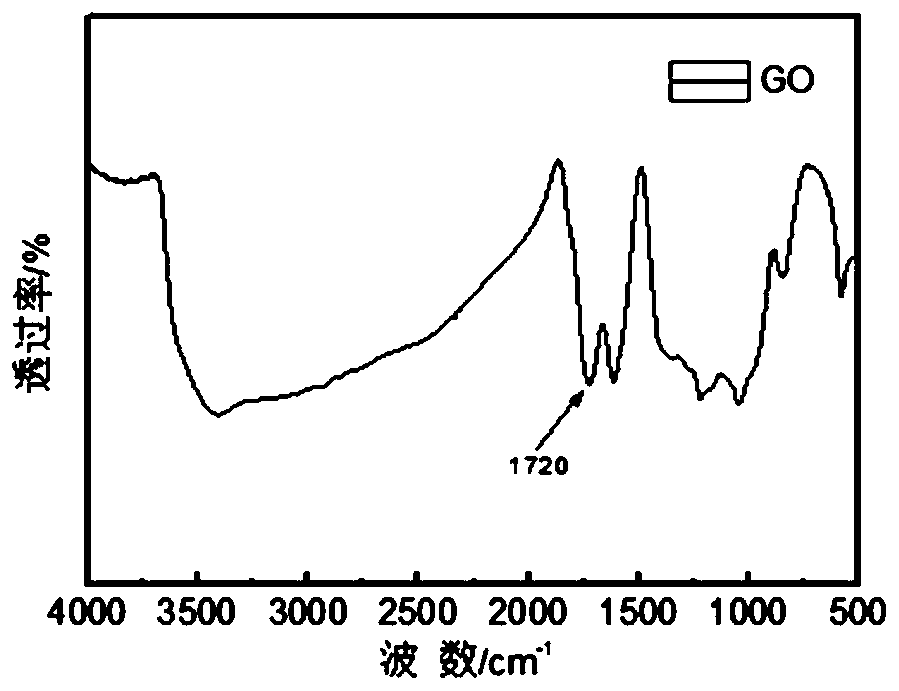

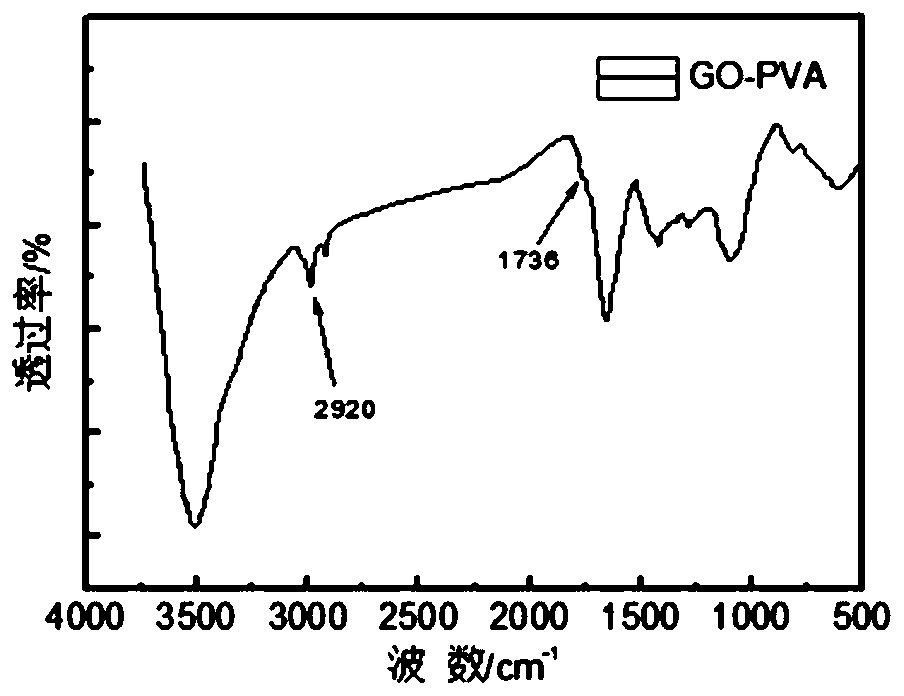

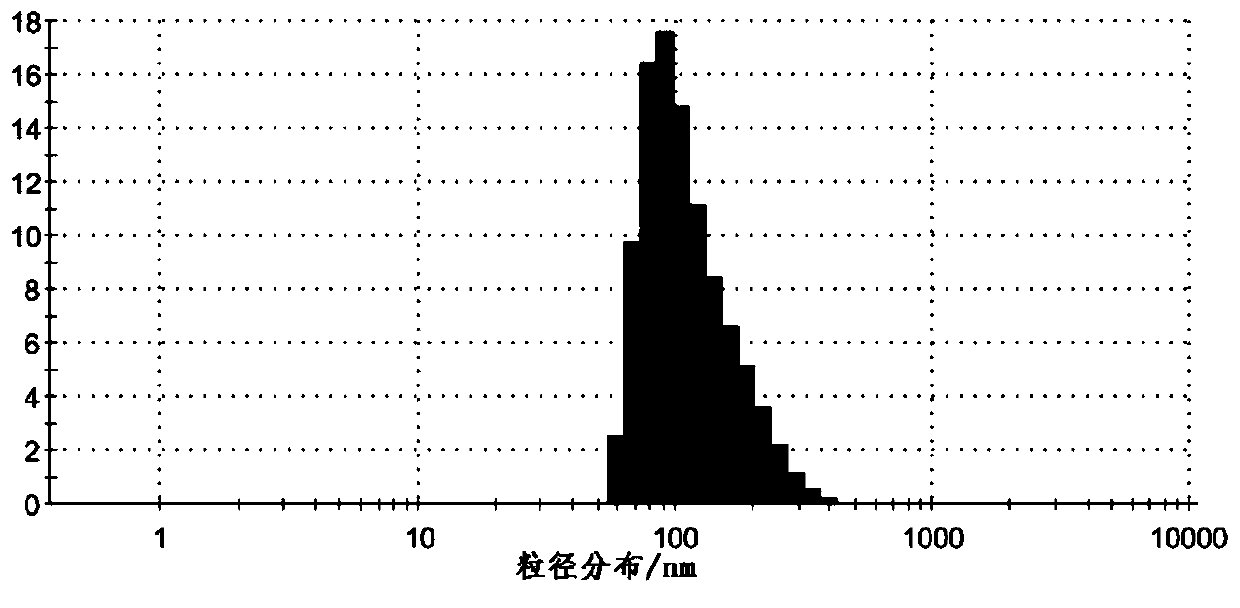

[0054]A preparation method of hydrophilic polymer modified graphene oxide nanoparticles, mainly comprising the following steps:

[0055] Step 1: Preparation of nanoparticle aqueous dispersion: disperse the purchased graphene oxide in distilled water at a concentration of 1-2mg / mL; mechanically stir at 500 rpm for 30min; Time 2-3h, power 40Hz;

[0056] Step 2: Prepare hydrophilic polymer aqueous solution: dissolve the purchased polymer powder in distilled water at a concentration of 20-100 mg / ml; mechanically stir at 500 rpm for 60 minutes until completely dissolved; the hydrophilic polymer includes : Polyvinyl alcohol, xanthan gum, cellulose, chitosan.

[0057] Step 3: Add a catalyst to activate the carboxyl groups on the surface of graphene oxide: Weigh 0.1-0.4g catalyst and add it to the graphene oxide aqueous dispersion in step 1, and stir while adding it dropwise at a stirring speed of 300 rpm to make the graphene oxide Surface carboxyl activation; catalysts include: 1-e...

Embodiment 1

[0061] Step 1: Preparation of nanoparticle aqueous dispersion: disperse the purchased graphene oxide in distilled water at a concentration of 1mg / mL; mechanically stir at 500 rpm for 30min; after stirring evenly, ultrasonically shear for 2h , power 40Hz;

[0062] Step 2: Prepare hydrophilic polymer aqueous solution: Dissolve the purchased hydrophilic polymer powder (polyvinyl alcohol, molecular weight 150,000-200,000) in distilled water at a concentration of 20 mg / mL; mechanically stir at 500 rpm, stir Polyvinyl alcohol 60min until completely dissolved;

[0063] Step 3: Add catalyst to activate carboxyl groups on the surface of graphene oxide: Weigh 0.1g of catalyst 4-dimethylaminopyridine (DMAP) and add it to 200ml of graphene oxide aqueous dispersion in step 1, stir while adding, and the stirring speed is 300 revs / min to activate the carboxyl groups on the surface of graphene oxide;

[0064] Step 4: Slowly add the polyvinyl alcohol aqueous solution prepared in step 2 to th...

Embodiment 2

[0067] Step 1: Preparation of nanoparticle aqueous dispersion: disperse the purchased graphene oxide in distilled water at a concentration of 1mg / mL; mechanically stir at 500 rpm for 30min; after stirring evenly, ultrasonically shear for 3h , power 40Hz;

[0068] Step 2: Preparation of hydrophilic polymer aqueous solution: Dissolve the purchased xanthan gum powder (molecular weight 100,000-150,000) in distilled water at a concentration of 30 mg / mL; stir mechanically at 500 rpm for 60 minutes until completely dissolved ;

[0069] Step 3: Add a catalyst to activate the carboxyl groups on the surface of graphene oxide: Weigh 0.2g of the catalyst 4-dimethylaminopyridine (DMAP) and add it to 200ml of the graphene oxide aqueous dispersion in step 1, and stir while adding it dropwise at a stirring speed of 300 revs / min to activate the carboxyl groups on the surface of graphene oxide;

[0070] Step 4: Slowly add the hydrophilic polymer aqueous solution prepared in step 2 to the grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com