Method and system for preparing propylene

A technology of propylene and propane, applied in the field of propylene preparation, can solve the problems of high energy consumption, unstable operation of the device, large investment, etc., and achieve the effects of reducing energy consumption of the device, reducing the number of equipment, and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

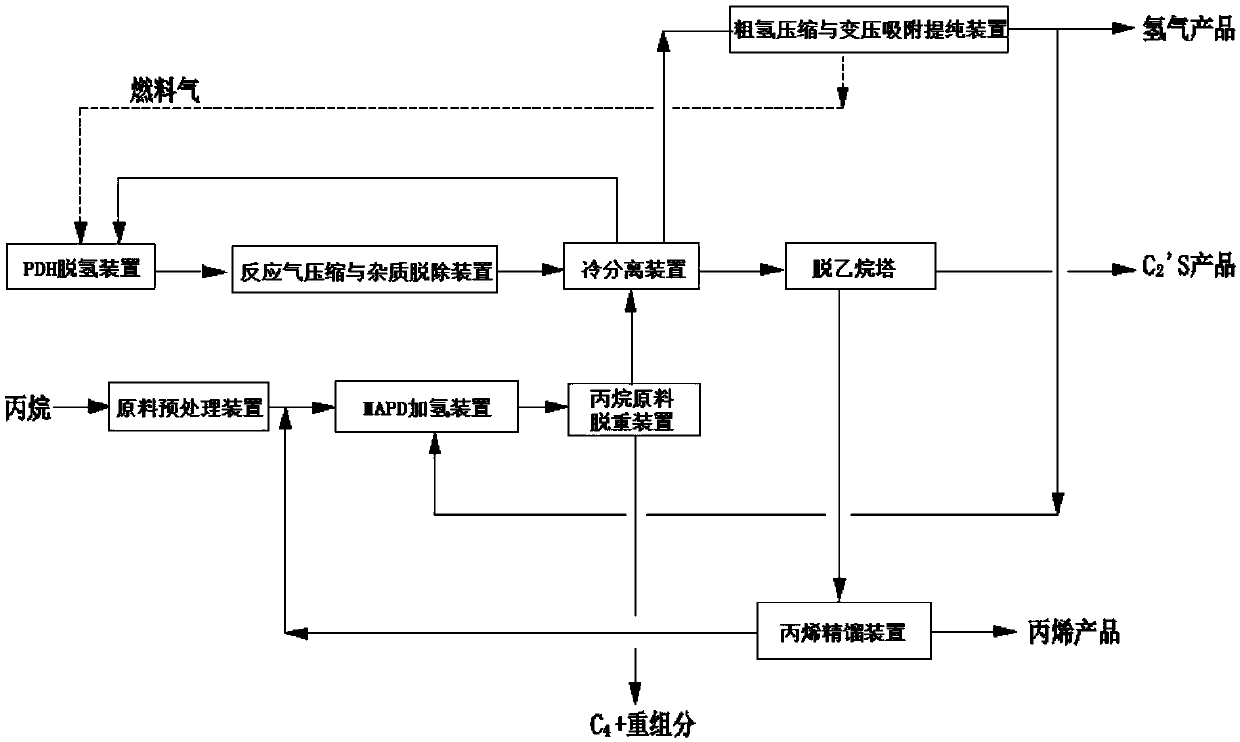

[0066] like figure 1 As shown, 99.28 tons / hour of fresh propane raw material is subjected to denitrification, heavy metal removal and dehydration drying pretreatment and then introduced into the MAPD hydrogenation unit for MAPD hydrogenation treatment to obtain the raw material after hydrotreatment, wherein the fresh propane raw material is The content of acetylene is 50ppm mol, the content of propadiene is 50ppm mol, and the hydrogen distribution amount of MAPD hydrotreating is 1.7. Subsequently, the raw material after hydrotreating is introduced into the deweighting device for deweighting treatment to remove heavy components such as carbon four, and then the raw material deweighted is introduced into the cold separation device, and becomes gaseous C after heat exchange in the cold separation device. 3 The material is then subjected to PDH dehydrogenation treatment. The material after dehydrogenation treatment is compressed, dechlorinated, dried, and desulfurized, and then e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com