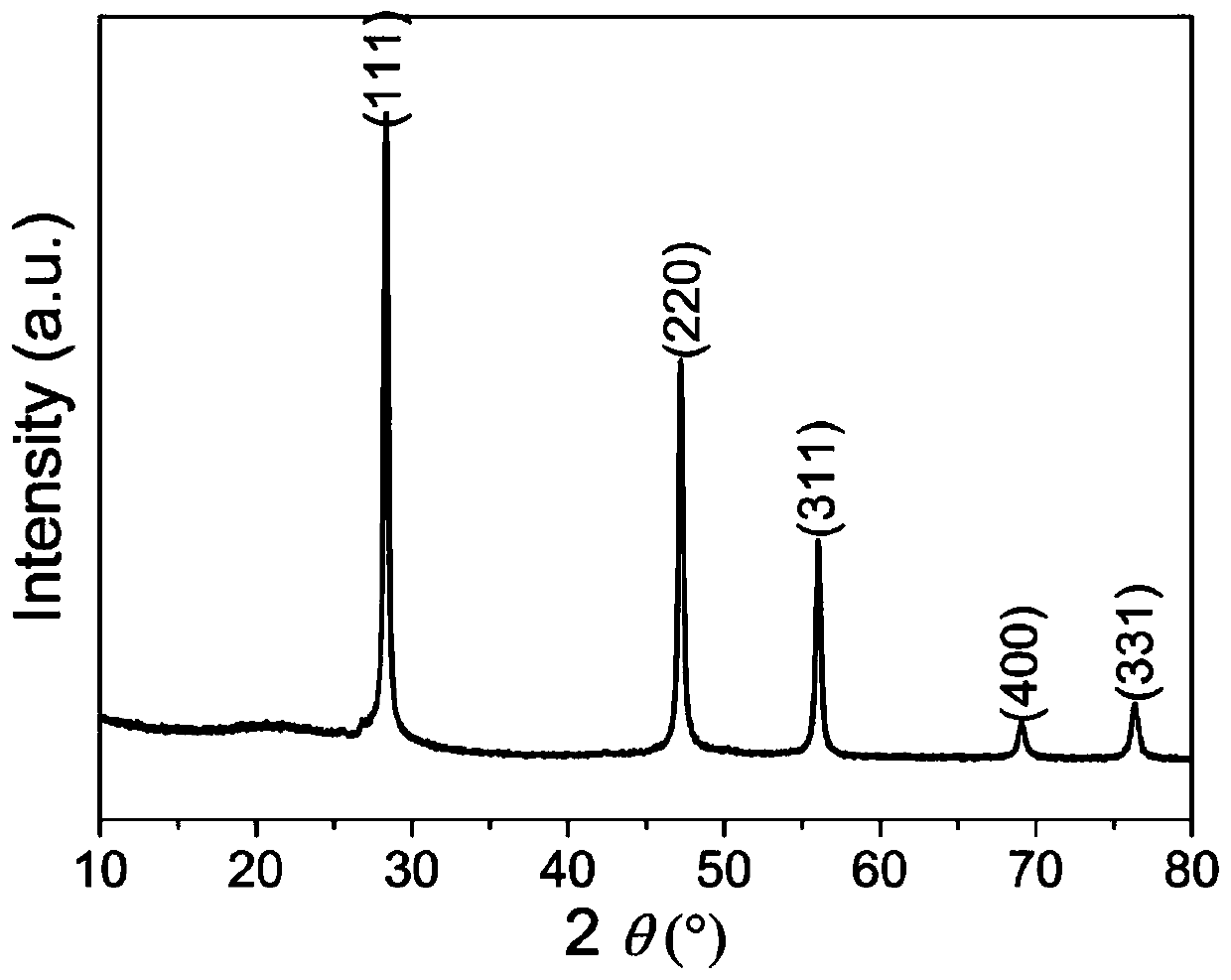

Preparation method of high-performance Si/C negative electrode material

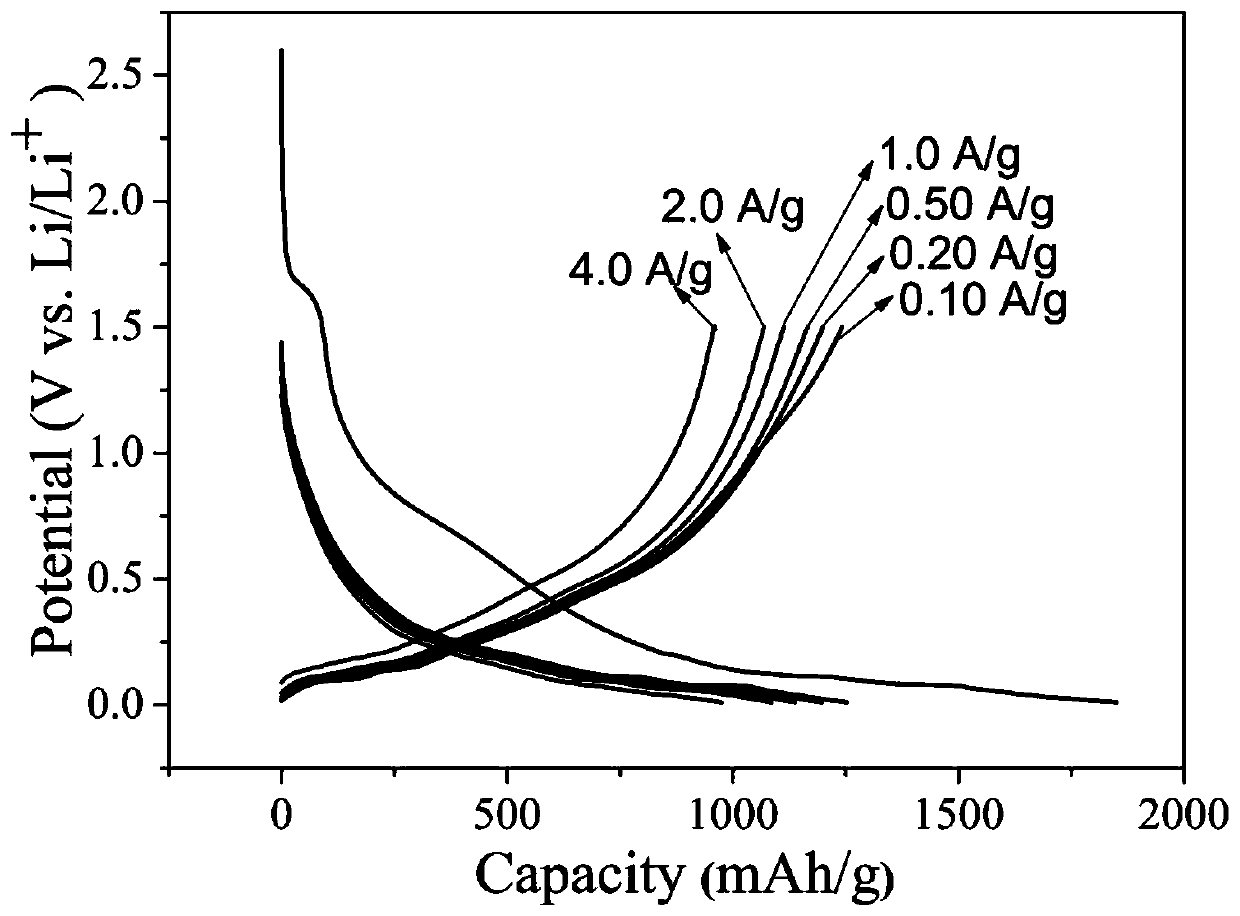

A negative electrode material and high-performance technology, which is applied in the field of preparation of high-performance Si/C negative electrode materials, can solve the problems of waste of high-quality C resources, complicated preparation methods, and high cost, and achieve excellent electrochemical performance, simplified preparation process, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of high-performance Si / C negative electrode material, comprising the following steps:

[0039] (1) removing impurities, cleaning and drying the rice husks obtained from the rice factory to obtain clean rice husk raw materials;

[0040] (2) Take 100g of clean rice husk and place it in the constant temperature zone of the horizontal tube furnace. 2 atmosphere (N 2 The flow rate of 100mL / min) was raised to 850°C at 5°C / min, and the N 2 Atmosphere switched to CO 2 Atmosphere (CO 2 The flow rate of 200mL / min), heat treatment at constant temperature for 2h, and then in N 2 Natural cooling in the atmosphere to below 100°C;

[0041] (3) Weigh NaCl2.86g, AlCl 3 10.94g, grind and mix the two in a dry environment, then weigh 3.6g of the heat-treated product of rice husk and 1.0g of aluminum powder (100-200 mesh), add them to a wear-resistant steel tank, add wear-resistant steel Ball 230g, seal the lid of the ball mill tank, open the inlet valve and outl...

Embodiment 2

[0047] A preparation method of high-performance Si / C negative electrode material, comprising the following steps:

[0048] (1) removing impurities, cleaning and drying the obtained rice husk;

[0049] (2) Take 100g of clean rice husk and place it in the constant temperature zone of the horizontal tube furnace. 2 atmosphere (N 2 The flow rate of 150mL / min) is raised to 950°C at 10°C / min, and the N 2 Atmosphere switched to CO 2 Atmosphere (CO 2 The flow rate of 600mL / min), heat treatment at constant temperature for 3h, and then in N 2 Natural cooling in the atmosphere to below 100°C;

[0050] (3) Weigh NaCl4.51g, AlCl 3 15.09g, grind and mix the two in a dry environment, then weigh 4.20g of the heat-treated product of rice husk and 2.33g of magnesium powder (100-200 mesh), add them to a wear-resistant steel tank, add wear-resistant steel Ball 340g, seal the lid of the ball mill tank, open the inlet valve and outlet valve on the tank lid, flush the raw materials in the tan...

Embodiment 3

[0055] A preparation method of high-performance Si / C negative electrode material, comprising the following steps:

[0056] (1) removing impurities, cleaning and drying the rice husk raw material;

[0057] (2) Take 100g of clean rice husk and place it in the constant temperature zone of the horizontal tube furnace. 2 atmosphere (N 2 The flow rate of 150mL / min) is raised to 900°C at 10°C / min, and the N 2 Atmosphere switched to CO 2 Atmosphere (CO 2 The flow rate is 400mL / min), heat treatment at constant temperature for 2h, and then in N 2 Natural cooling in the atmosphere to below 100°C;

[0058] (3) Weigh NaCl4.93g, AlCl 3 15.20g, grind and mix the two in a dry environment, then weigh 4.5g of the heat-treated product of rice husk and 1.25g of aluminum powder (100-200 mesh), add them to a wear-resistant steel tank, add wear-resistant steel Ball 365g, seal the lid of the ball mill tank, open the inlet valve and outlet valve on the tank lid, flush the raw materials in the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Coulombic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com