Concrete accelerator for subway construction

A quick-setting agent and concrete technology, applied in the field of concrete quick-setting agent, can solve the problems of aluminate aggregates, reduce the service life of buildings, hidden safety hazards, etc., achieve the effects of wide sources, increase strength, and prevent pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

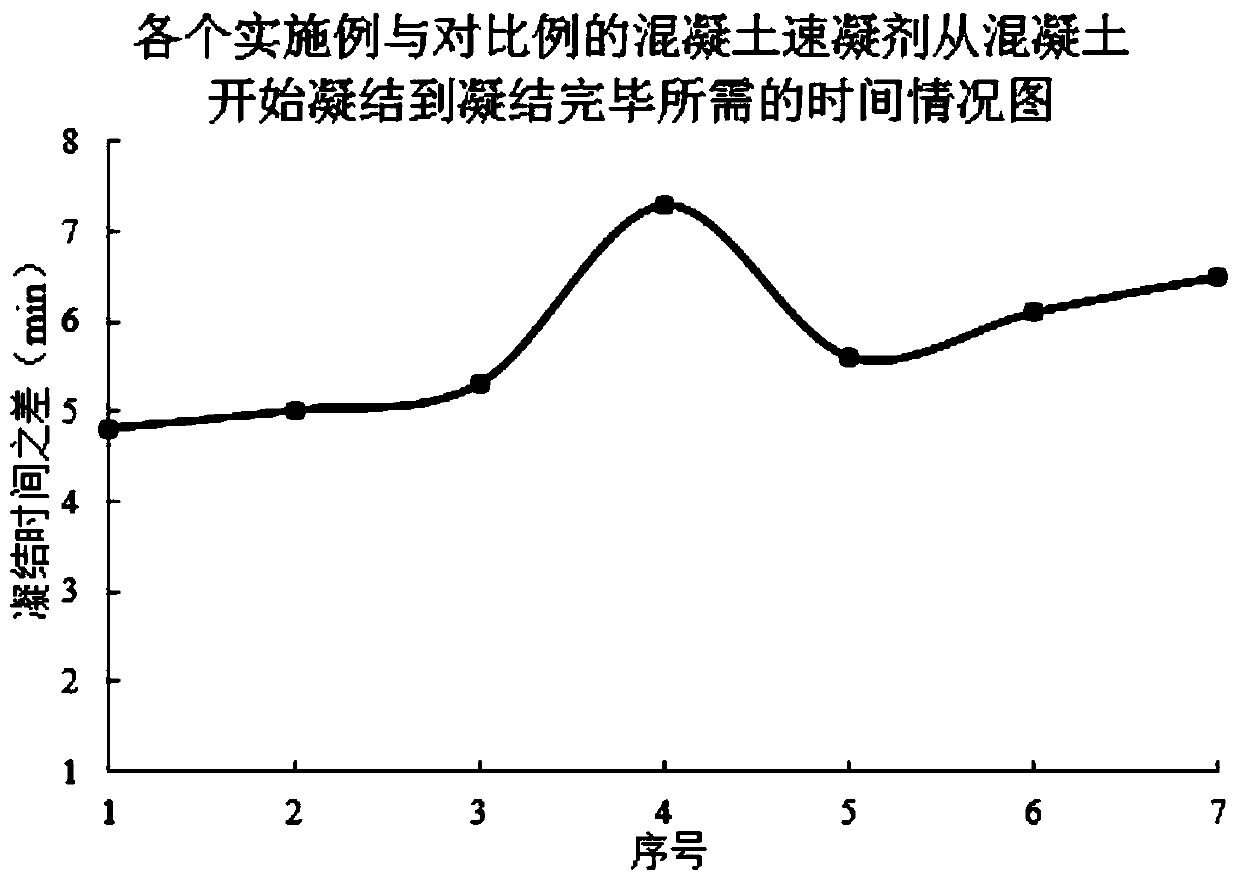

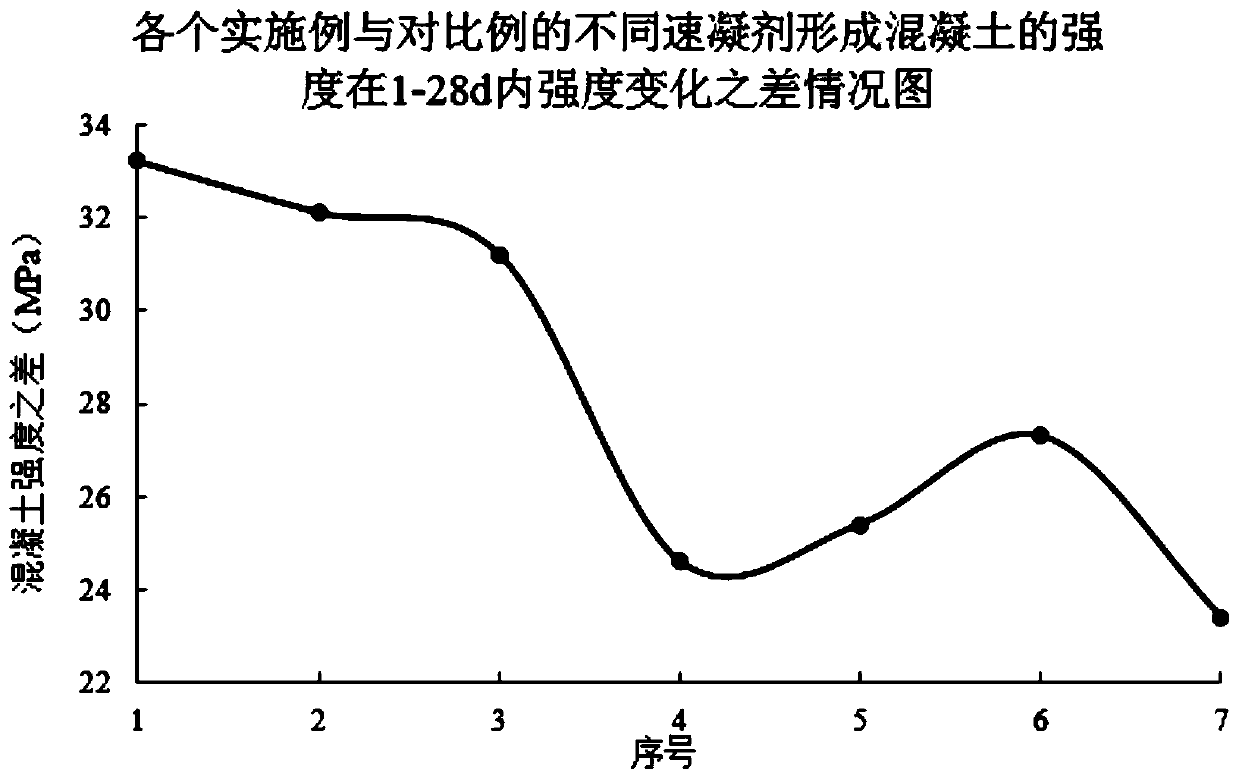

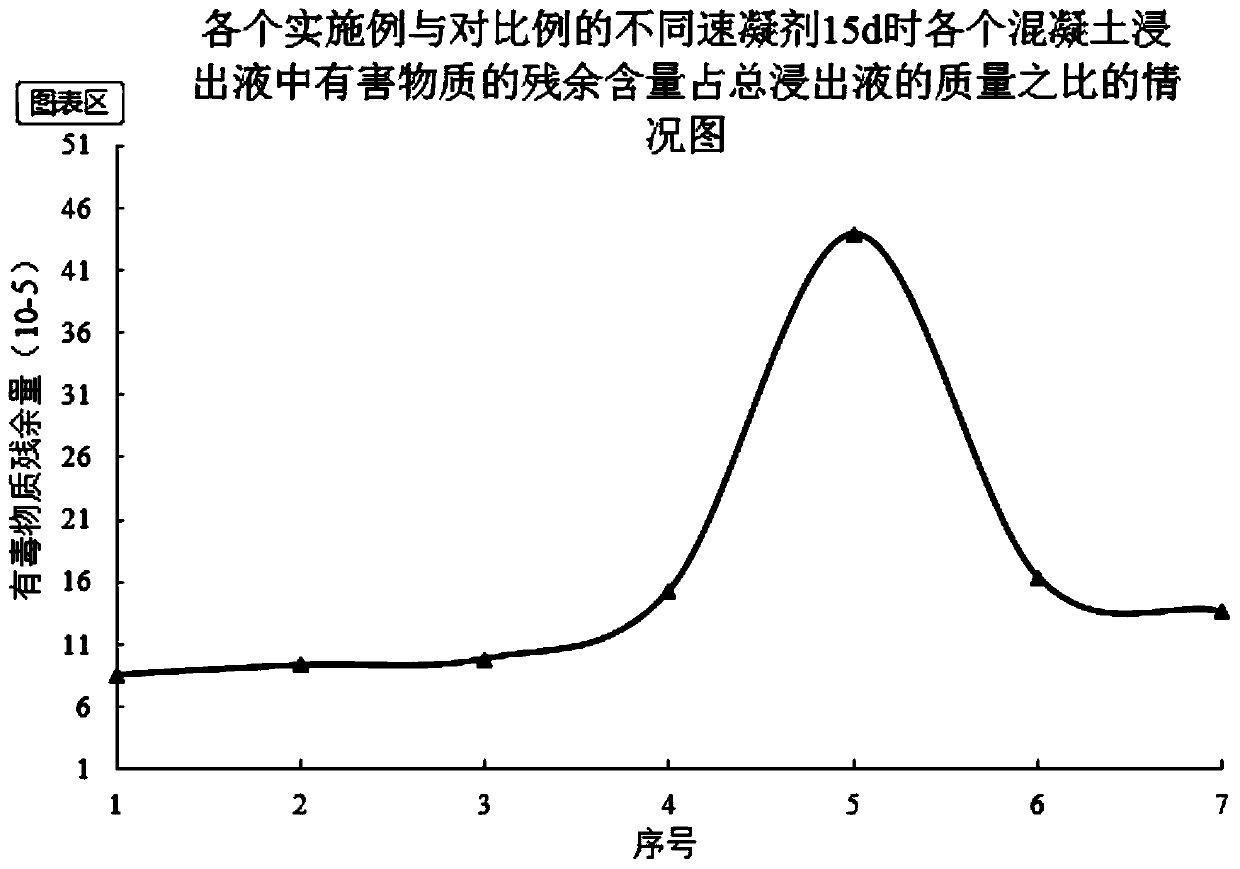

Examples

Embodiment 1

[0030] A concrete accelerator for subway construction, comprising the following raw materials in parts by weight: 35 parts of sodium polyacrylate, 40 parts of isopropanol, 25 parts of marine microalgae polysaccharides, 25 parts of aluminum sulfate, 20 parts of acetic acid; The marine microalgae polysaccharide is limited as a complexing agent, and the marine microalgae polysaccharide is a flat algae polysaccharide separated and purified from its photosynthetic products after expansion and propagation of flat algae; the separation and purification include the following steps:

[0031] S1 Weigh the flat algae dry powder, add titanium powder particles as the grinding medium, and grind it into powder ultrafinely;

[0032] S2 Wash and purify the obtained superfine powder in absolute ethanol to obtain a purified precipitate, then add trichloroacetic acid to partially dissolve the purified precipitate, then use absolute ethanol to further wash the precipitate, and then dissolve the pre...

Embodiment 2

[0040] 20 parts of sodium polyacrylate, 30 parts of isopropanol, 20 parts of marine microalgae polysaccharide, 20 parts of aluminum sulfate, and 25 parts of acetic acid were used as raw materials in the quick-setting agent, and the remaining steps and raw materials were the same as in Example 1.

Embodiment 3

[0042] 40 parts of sodium polyacrylate, 50 parts of isopropanol, 30 parts of marine microalgae polysaccharide, 30 parts of aluminum sulfate, and 25 parts of acetic acid were used as raw materials in the accelerator, and the remaining steps and raw materials were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com