Spongy pervious concrete as well as preparation method and application thereof

A permeable concrete and sponge technology, applied in the field of concrete, can solve the problems of large pores, insufficient decontamination ability, and low strength of permeable concrete, and achieve the effects of enhancement and beauty, enhanced water purification ability, and enhanced durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

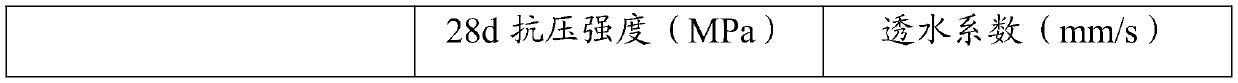

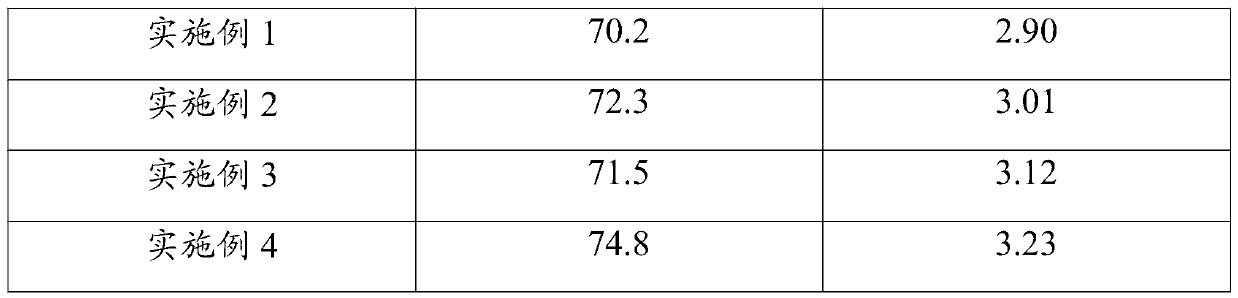

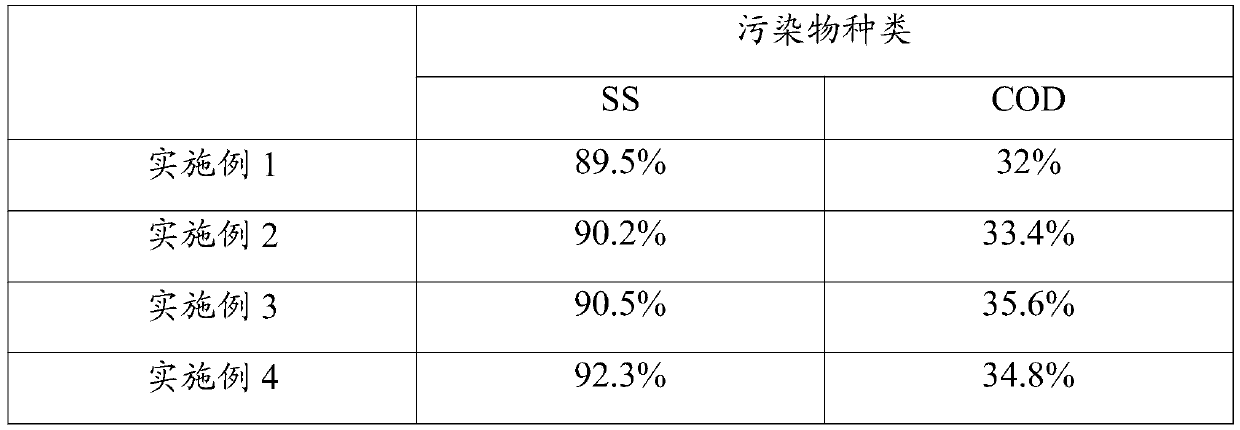

Examples

preparation example Construction

[0054] The present invention also discloses a preparation method of sponge body permeable concrete, said method specifically comprising the following steps:

[0055] (1) Weigh the raw materials of the following formula respectively: 75-85 parts of aggregate, 10-20 parts of cement, 5-10 parts of water, 0.3-0.8 parts of adhesive, 0.2-0.6 parts of admixture, 1.0-2.0 parts of inorganic pigment ;

[0056] (2) fully mixing the admixture and water taken in step (1) to obtain a mixed solution;

[0057] (3) Put the adhesive and aggregate weighed in step (1) into the mixer and stir for 25 to 35 seconds, then add the mixed solution obtained in step (2) and stir evenly, and finally add the cement and inorganic pigment weighed in step (1), Continue stirring to obtain the sponge body permeable concrete of the present invention.

[0058] In order to further realize technical effect of the present invention, in described step (3), the stirring time of stirring for the second time and stirri...

Embodiment 1

[0065] A preparation method of sponge body permeable concrete, said method specifically comprising the steps of:

[0066] (1) Take the raw materials of following formula quantity respectively: 78 parts of aggregate, 12 parts of cement, 6 parts of water, 0.48 part of adhesive, 0.25 part of admixture, 1.2 part of inorganic pigment;

[0067] (2) fully mixing the admixture and water taken in step (1) to obtain a mixed solution;

[0068] (3) Put the adhesive and aggregate weighed in step (1) into the mixer and stir for 30s, then add the mixed solution obtained in step (2) and stir for 120s to mix evenly, and finally add the cement and inorganic pigments weighed in step (1), Continue to stir for 120s to obtain the sponge body permeable concrete of the present invention.

Embodiment 2

[0070] A preparation method of sponge body permeable concrete, said method specifically comprising the steps of:

[0071] (1) Take by weighing the raw materials of following formula quantity respectively: 80 parts of aggregate, 14 parts of cement, 7 parts of water, 0.50 part of adhesive, 0.35 part of admixture, 1.4 part of inorganic pigment;

[0072] (2) fully mixing the admixture and water taken in step (1) to obtain a mixed solution;

[0073] (3) Put the adhesive and aggregate weighed in step (1) into the mixer and stir for 30s, then add the mixed solution obtained in step (2) and stir for 120s to mix evenly, and finally add the cement and inorganic pigments weighed in step (1), Continue to stir for 120s to obtain the sponge body permeable concrete of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com