Ferronickel residue light ceramsite and preparation process thereof

A technology of lightweight ceramsite and nickel-iron slag, which is applied in the field of lightweight ceramsite, can solve the problems of low industrial utilization of nickel-iron slag, achieve the effects of reducing production costs, promoting depolymerization, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

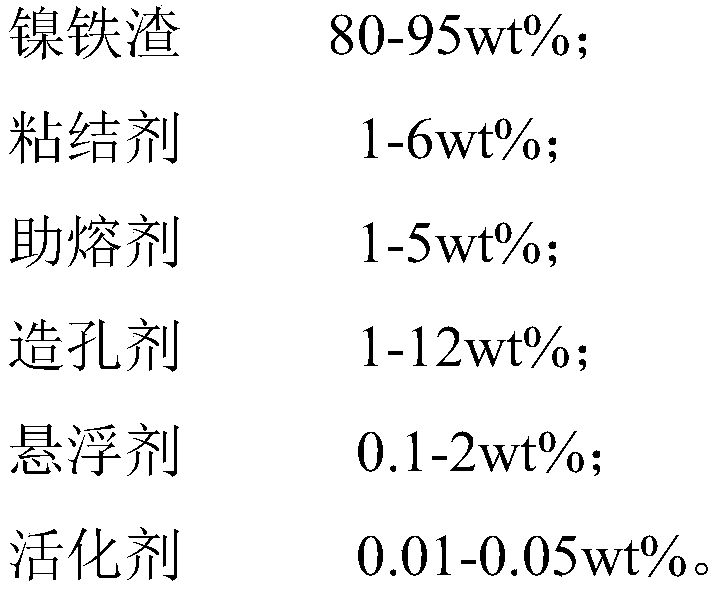

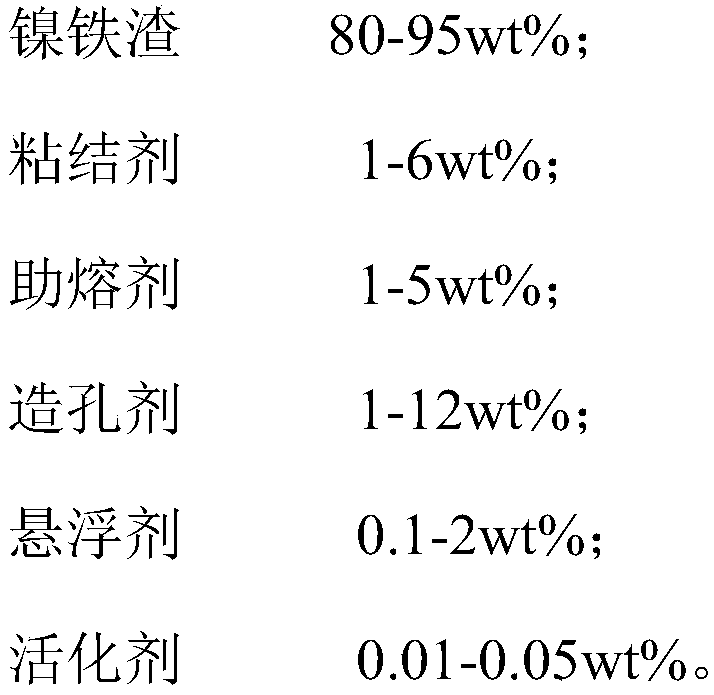

[0034] The nickel-iron slag lightweight ceramsite in this embodiment, based on the total amount of raw materials for the preparation of the ceramsite, includes the following raw material components in mass content:

[0035]

[0036]

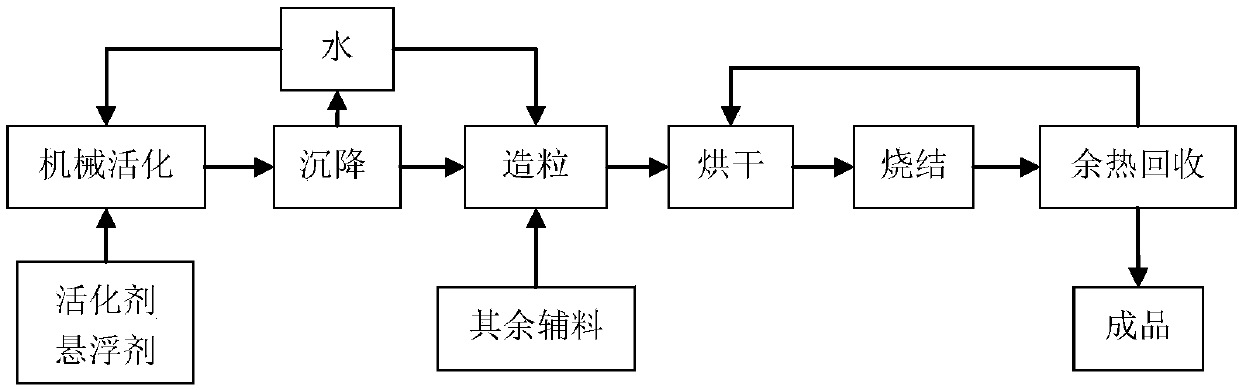

[0037] Such as figure 1 The process flow diagram shown, the preparation method of nickel-iron slag lightweight ceramsite described in this embodiment comprises the following steps:

[0038] (1) get selected amount of described ferronickel slag (particle size is less than 150 μ m, sieve residue≤10%), activator and suspending agent mix, and add the water that accounts for 30wt% of ferronickel slag quality, place ball mill And add ceramic balls as grinding balls for mechanical activation, the time is 4h;

[0039] (2) The activated mixture is subjected to static sedimentation treatment, and the solid particles are collected after solid-liquid separation through filtration; the separated water can be used for recycling and adding to the mechani...

Embodiment 2

[0043] The nickel-iron slag lightweight ceramsite in this embodiment, based on the total amount of raw materials for the preparation of the ceramsite, includes the following raw material components in mass content:

[0044]

[0045] Such as figure 1 The process flow diagram shown, the preparation method of nickel-iron slag lightweight ceramsite described in this embodiment comprises the following steps:

[0046] (1) get selected amount of said ferronickel slag (particle size is less than 150 μ m, sieve residue≤10%), activator and suspending agent are mixed, and add the water that accounts for 33wt% of ferronickel slag quality, place in ball mill And add ceramic balls as grinding balls for mechanical activation for 4 hours;

[0047] (2) The activated mixture is subjected to static sedimentation treatment, and the solid particles are collected after solid-liquid separation through filtration; the separated water can be used for recycling and adding to the mechanical activati...

Embodiment 3

[0051] The nickel-iron slag lightweight ceramsite in this embodiment, based on the total amount of raw materials for the preparation of the ceramsite, includes the following raw material components in mass content:

[0052]

[0053] Such as figure 1 The process flow diagram shown, the preparation method of nickel-iron slag lightweight ceramsite described in this embodiment comprises the following steps:

[0054] (1) get selected amount of said ferronickel slag (particle size is less than 150 μ m, sieve residue≤10%), activator and suspending agent are mixed, and add the water that accounts for 38wt% of ferronickel slag quality, place ball mill And add ceramic balls as grinding balls for mechanical activation for 5 hours;

[0055] (2) The activated mixture is subjected to static sedimentation treatment, and the solid particles are collected after solid-liquid separation through filtration; the separated water can be used for recycling and adding to the mechanical activation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com