Synthesis method of flame-retardant polyester ether polyol

A technology of polyester ether polyol and polyester polyol, applied in the field of chemical synthesis, can solve the problem of low price, and achieve the effects of low price, good flame retardancy and high system compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

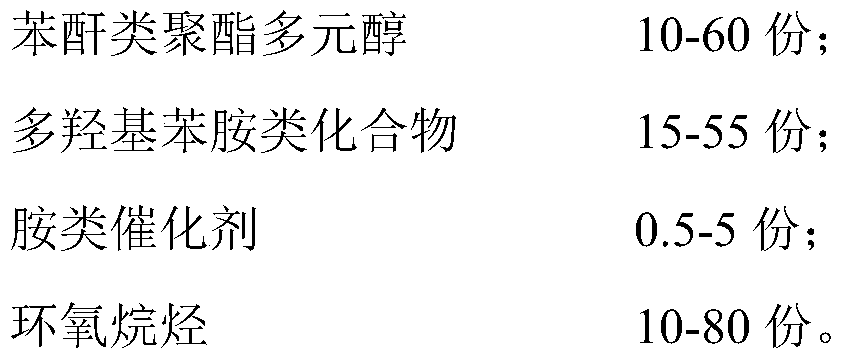

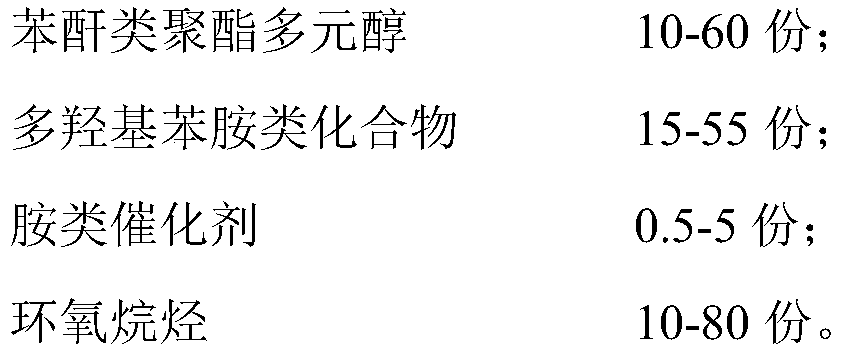

Method used

Image

Examples

Embodiment 1

[0025] Add 500g of tetrachlorophthalic anhydride polyester polyol and 150g of hexamethylol melamine into the reactor in turn, after nitrogen replacement, raise the temperature of the reactor to 70°C, then add 80g of propylene oxide, react at this temperature for 1h, negative Inject 15g of trimethylamine catalyst under pressure (-0.05MPa), raise the temperature to 120°C, slowly pass in 310g of propylene oxide, maintain the pressure at 0.15MPa during this period, continue to react at this temperature and pressure for 3 hours, and then refine the product to obtain tetrachlorophthalic anhydride Flame-retardant polyester ether polyol, the performance index is shown in Table 1.

Embodiment 2

[0027] Add 500g of tetrachlorophthalic anhydride polyester polyol and 200g of hydroxyethylhexahydro-s-triazine to the reactor in turn, after nitrogen replacement, raise the temperature of the reactor to 90°C, then add 70g of ethylene oxide, at this temperature React for 2 hours, draw 12g of dimethylamine catalyst under negative pressure (-0.09MPa), raise the temperature to 110°C, slowly feed 350g of ethylene oxide, maintain the pressure at 0.15MPa during this period, continue to react at this temperature and pressure for 4 hours, and then refine it That is to obtain the product tetrachlorophthalic anhydride flame-retardant polyester ether polyol, the performance index is shown in Table 1.

Embodiment 3

[0029] Add 400g of tetrabromophthalic anhydride polyester polyol and 150g of 2,3,6,7,10,11-hexahydroxytriphenylenebenzene into the reaction kettle in sequence, after nitrogen replacement, raise the temperature of the reaction kettle to 80°C, and then add 80g propylene oxide, reacted at this temperature for 2h, sucked in 11g triethylamine catalyst under negative pressure (0.02MPa), raised the temperature to 130°C, and slowly introduced 310g propylene oxide, during which the pressure was maintained at 0.2MPa, at this temperature and pressure Continue the reaction for 3.5 hours, and then refine the product to obtain the tetrabromophthalic anhydride flame-retardant polyester ether polyol. The performance indicators are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com