Tracking-resistant polyvinyl chloride insulating material, and preparation method and application thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, which is used in insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problem of few reports on the electrical tracking resistance of PVC insulating materials, poor electrical tracking resistance, etc. problems, to achieve the effect of improving the tracking resistance, prolonging the service life and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

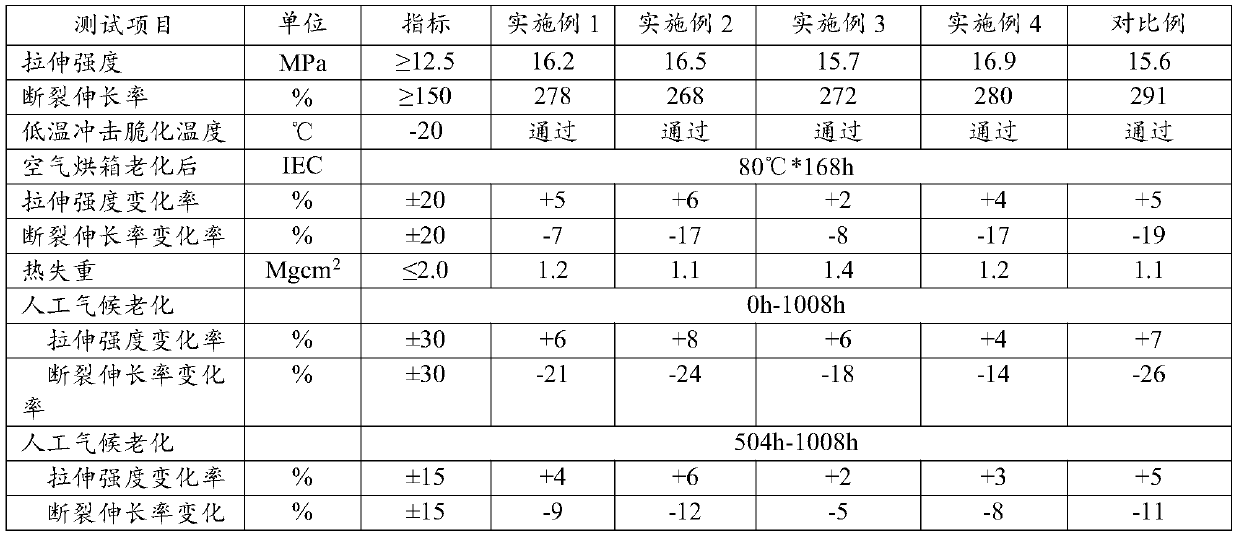

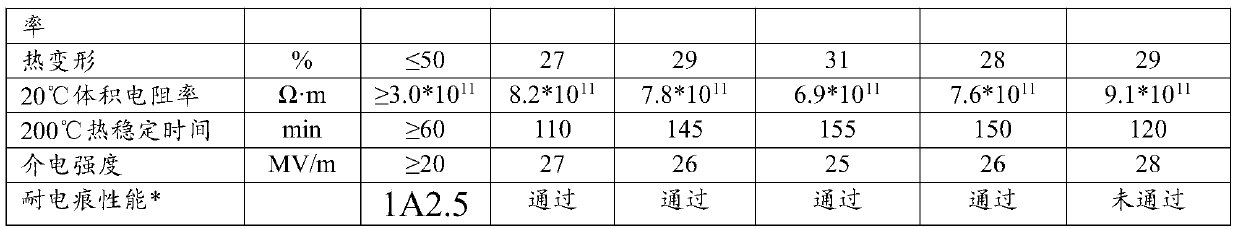

Examples

Embodiment 1

[0033] 1. Experimental materials

[0034] 50 kg of polyvinyl chloride resin A (S-75); 50 kg of polyvinyl chloride resin B (S-85); 30 kg of plasticizer dioctyl terephthalate; plasticizer halogenated polyether fatty acid ester 20 kg; nano-active calcium carbonate (SPSL-1) 10 kg; high-purity sedimentation magnesium hydroxide (MAGNIFINH5) 30 kg; precipitation aluminum hydroxide (MARTINALOL-104LEO) 15 kg; nano-scale titanium dioxide 5 kg; environmental calcium Zinc composite stabilizer (MC91717KA) 6 kg; hindered benzoate light stabilizer (CYASORBUV-2908) 1.2 kg; benzophenone ultraviolet absorber (CHIMASSORB81) 2.5 kg; calcined clay 10 kg.

[0035] 2. Preparation method:

[0036] a, with 50 kilograms of polyvinyl chloride resin B (S-85); 30 kilograms of plasticizer dioctyl terephthalate; 20 kilograms of plasticizer halogenated polyether fatty acid esters; nano active calcium carbonate (SPSL- 1) 10 kg; 30 kg of high-purity sinking magnesium hydroxide (MAGNIFINH5); 15 kg of precipit...

Embodiment 2

[0040] 1. Experimental materials

[0041]50 kg of polyvinyl chloride resin A (S-75); 50 kg of polyvinyl chloride resin B (S-85); 40 kg of plasticizer dioctyl terephthalate; plasticizer halogenated polyether fatty acid ester 15 kg; nano-active calcium carbonate (SPSL-1) 15 kg; high-purity sedimentation method magnesium hydroxide (MAGNIFINH5) 35 kg; precipitation method aluminum hydroxide (MARTINALOL-104LEO) 20 kg; nano-scale titanium dioxide 5 kg; environmental calcium Zinc composite stabilizer (MC91717KA) 8 kg; hindered benzoate light stabilizer (CYASORBUV-2908) 1.8 kg; benzophenone ultraviolet absorber (CHIMASSORB81) 3 kg; calcined clay 15 kg.

[0042] 2. Preparation method:

[0043] a, 50 kilograms of polyvinyl chloride resin A (S-75); 50 kilograms of polyvinyl chloride resin B (S-85); 40 kilograms of plasticizer dioctyl terephthalate; plasticizer halogenated polyether group 15 kg of fatty acid ester; 15 kg of nano-active calcium carbonate (SPSL-1); 35 kg of high-purity se...

Embodiment 3

[0047] 1. Experimental materials

[0048] 50 kg of polyvinyl chloride resin A (S-75); 50 kg of polyvinyl chloride resin B (S-85); 50 kg of plasticizer dioctyl terephthalate; plasticizer halogenated polyether fatty acid ester 10 kg; nano-active calcium carbonate (SPSL-1) 10 kg; high-purity sedimentation method magnesium hydroxide (MAGNIFINH5) 40 kg; precipitation method aluminum hydroxide (MARTINALOL-104LEO) 15 kg; nano-scale titanium dioxide 10 kg; environmental calcium Zinc composite stabilizer (MC91717KA) 8 kg; hindered benzoate light stabilizer (CYASORBUV-2908) 1.8 kg; benzophenone ultraviolet absorber (CHIMASSORB81) 2 kg; calcined clay 20 kg.

[0049] 2. Preparation method:

[0050] a, 50 kilograms of polyvinyl chloride resin A (S-75); 50 kilograms of polyvinyl chloride resin B (S-85); 50 kilograms of plasticizer dioctyl terephthalate; plasticizer halogenated polyether group 10 kg of fatty acid ester; 10 kg of nano-active calcium carbonate (SPSL-1); 40 kg of high-purity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com