Laser welding tinning device and welding method

A laser welding and laser position technology, applied in tin feeding devices, auxiliary devices, welding equipment, etc., can solve the problem of bending or offset, can not accurately judge the contact force between the tin wire and the solder joint, can not accurately judge the tin wire and welding Points and other issues to achieve the effect of compensating for the effect of the welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

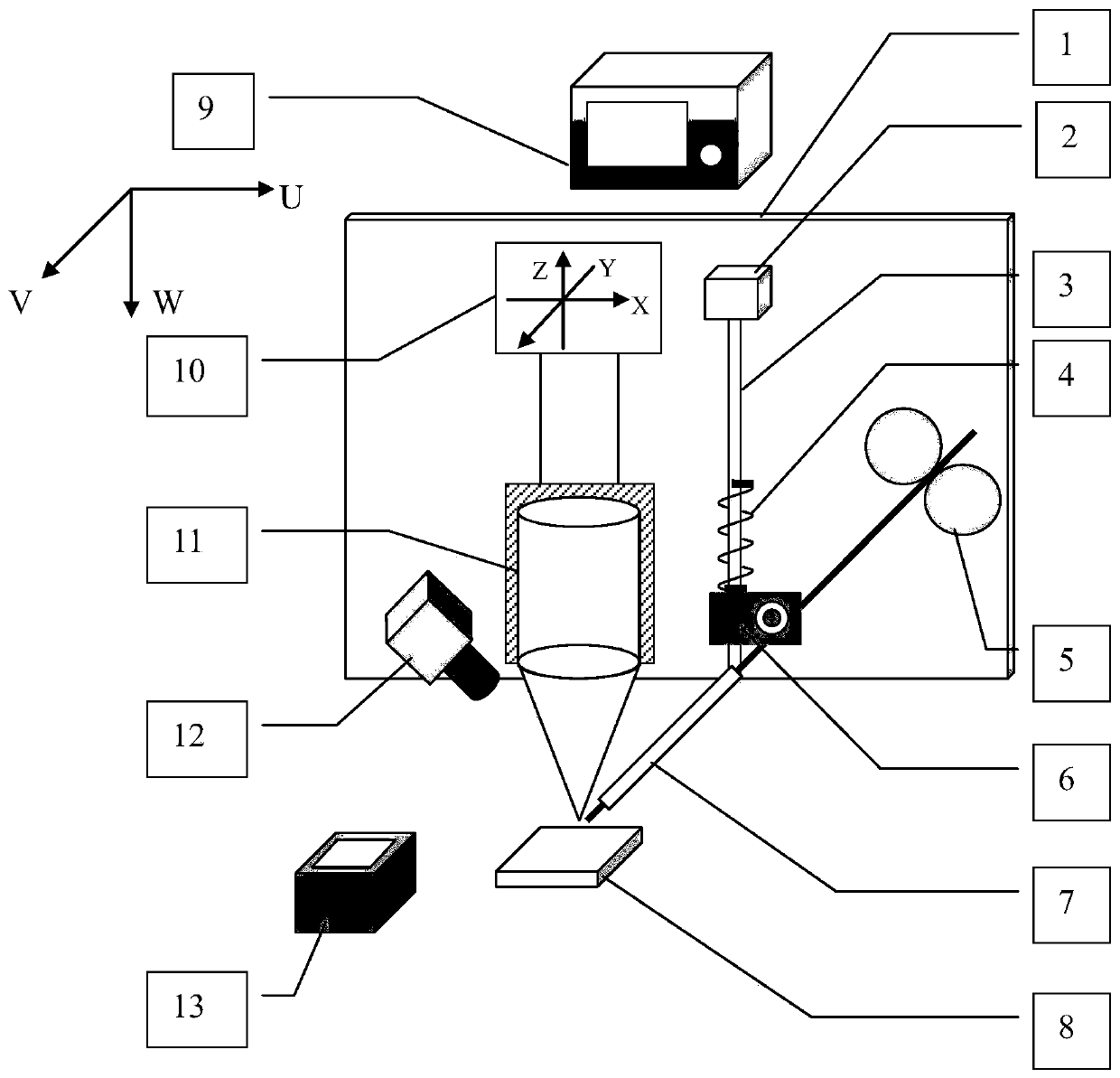

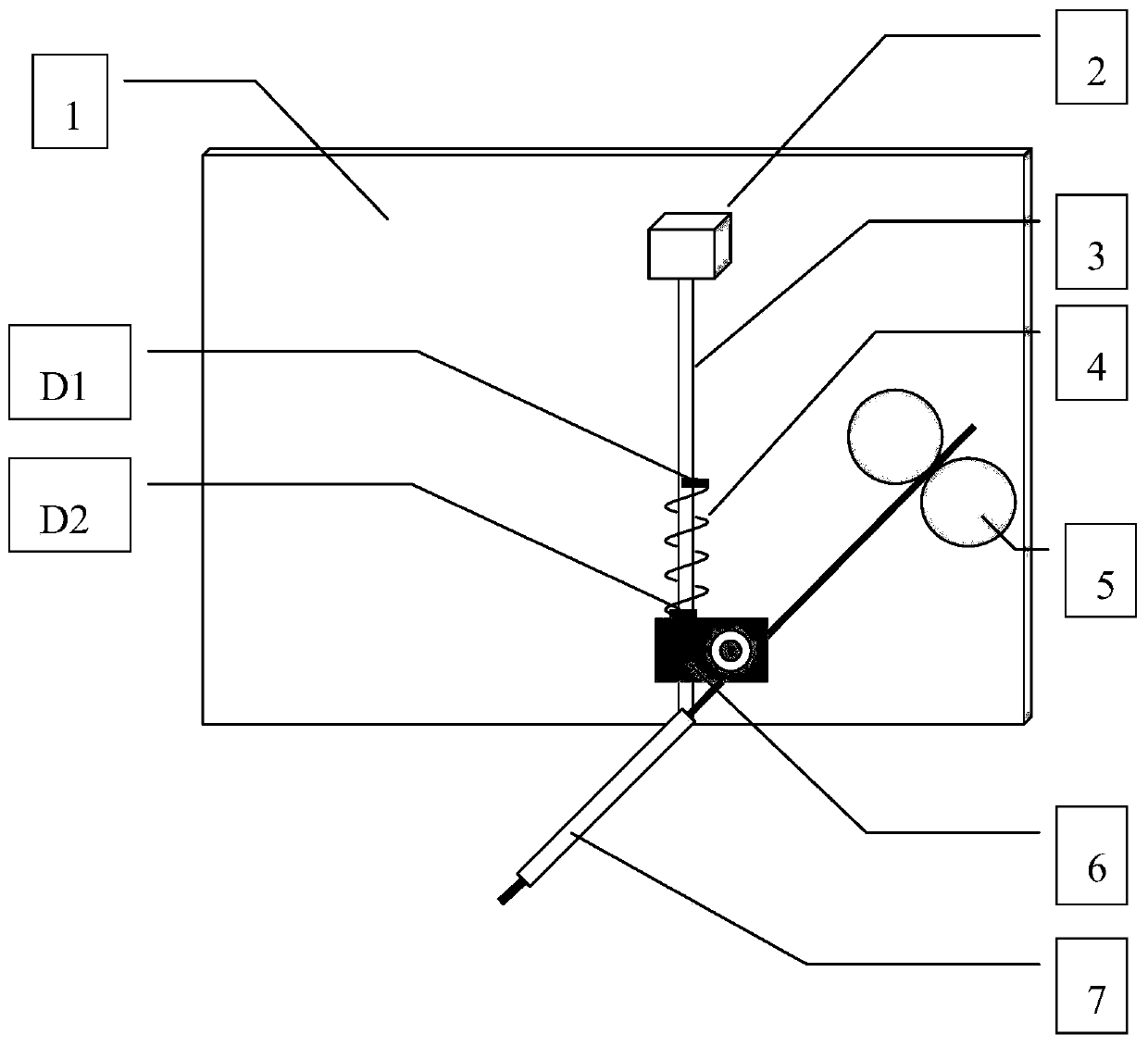

[0084] Embodiment 1: SMD welding

[0085] refer to Figure 4 with Figure 5 , it is necessary to ensure that the tin wire is in good contact with the solder joint during patch welding, that is, the contact force f is always kept at f during the welding process 0 , f 0 It can be selected according to the characteristics of tin wire and welding process. In the positioning stage, when the contact force between the tin wire and the pad is at f b When within the range of ±Δf, stop positioning immediately. During the welding process, the pushing speed of the tin wire is adjusted by the PID algorithm. When the tin tip is not melted, if the tin is continuously fed, the contact force f between the tin wire and the pad will increase, and the tin feeding speed should be reduced at this time; When the wire melts too fast, the contact force f between the tin wire and the pad decreases, and the tin feeding speed should be accelerated at this time.

Embodiment 2

[0086] Embodiment 2: pin welding

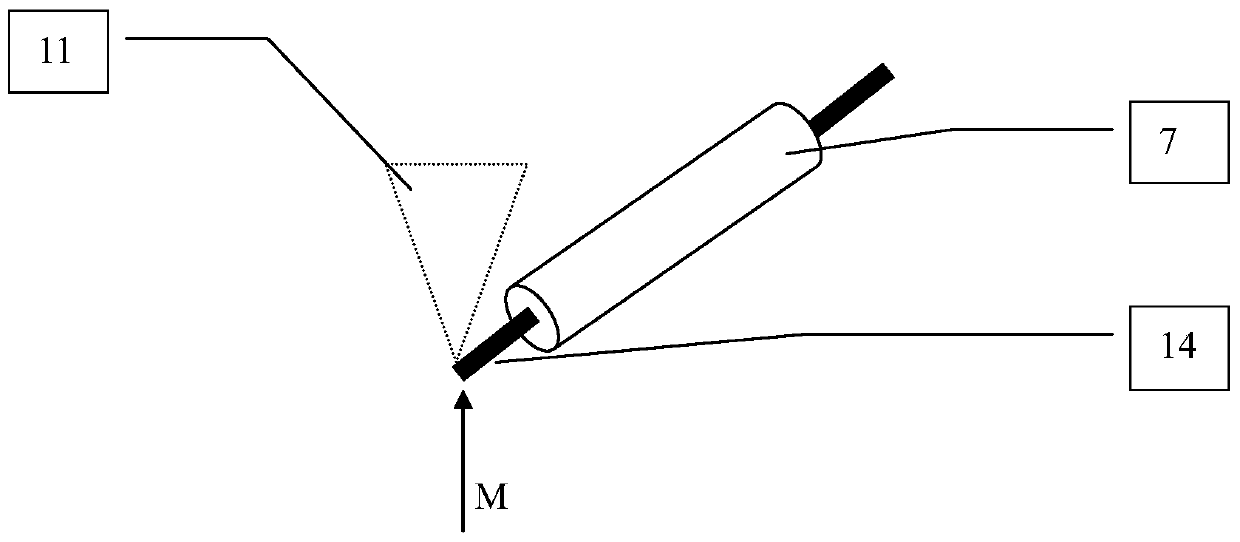

[0087] refer to Figure 4 with Image 6 , when the pin pin 15 is deformed, in the positioning stage of the probe head 14, the tin tip 16 will be deflected to the right after contacting the top of the pin 15, and the angle sensor 2 records the deflection angle of the tin wire 14, but at this time the balance spring 4 The vertical contact force is 0, so the device continues to move downward. During the movement, under the restoring force of the balance spring 4, the tin tip 16 is always in contact with the contact pin 15 until the contact force f is within f b within the range of ±Δf. During the contact process between the tin tip 16 and the contact pin 15, the running track of the tin tip 16 is close to the shape of the contact pin 15, such as Image 6 As shown, the tin tip 16 can effectively avoid the interference of the pin pin 15 and be accurately positioned to the pad 8 to be soldered.

[0088] The invention utilizes the position feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com