Porous organic material, preparation method thereof and application thereof

A porous organic material and organic technology, applied in the field of porous materials, can solve the problem of difficult to realize the preparation of porous organic materials with higher specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

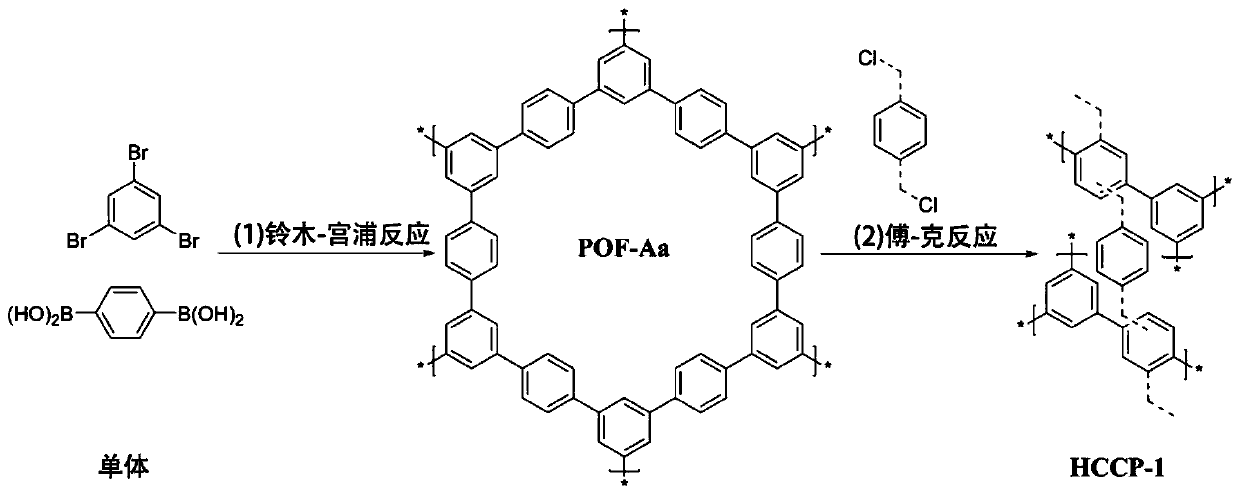

[0094] The invention provides a method for preparing a porous organic material, comprising the following steps:

[0095] Coupling and polymerization of organic monomers to obtain two-dimensional topological materials;

[0096] Mixing the two-dimensional topological material, catalyst, cross-linking agent and solvent, and performing a Friedel-Crafts reaction to obtain a porous organic material;

[0097] The organic monomer preferably includes one or more of aromatic halides, boronic acid substituted aromatic compounds, boronic acid pinacol ester substituted aromatic compounds, alkynyl substituted aromatic compounds and alkenyl substituted aromatic compounds.

[0098] In the present invention, unless otherwise specified, the raw materials of each component are commercially available products well known to those skilled in the art.

[0099] In the invention, organic monomers are subjected to coupling polymerization reaction to obtain two-dimensional topological materials.

[01...

Embodiment 1

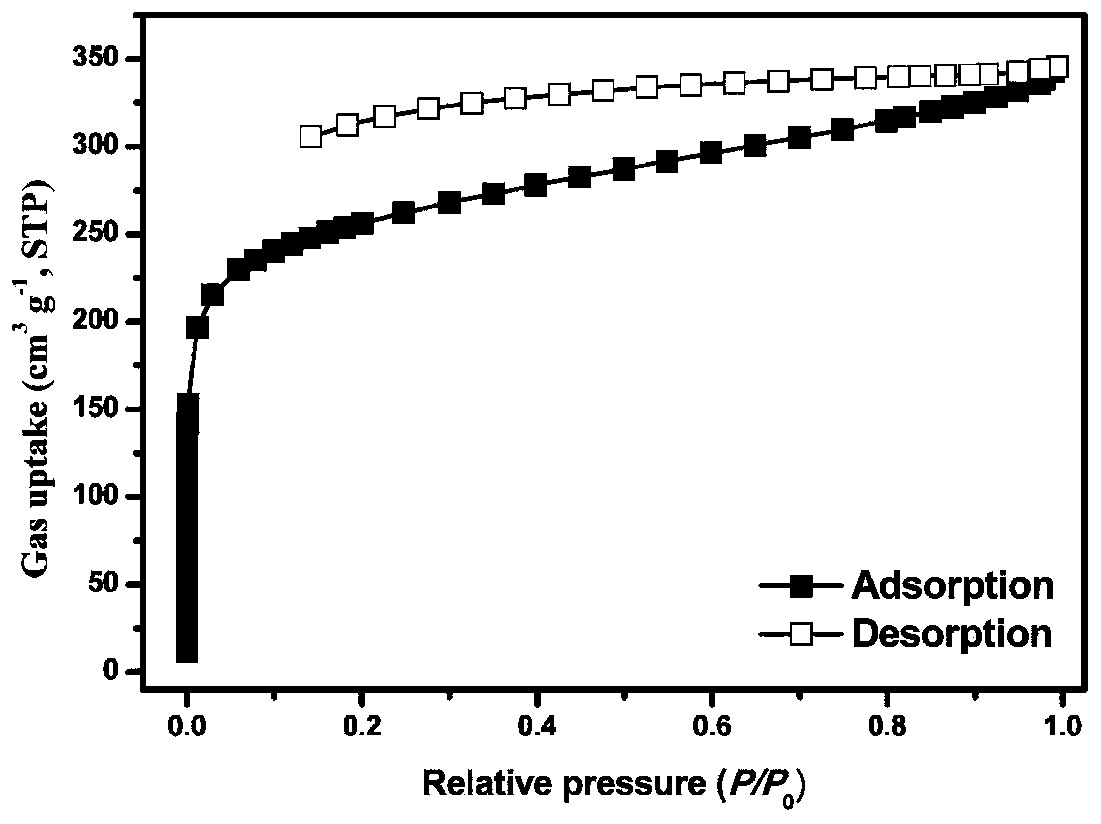

[0124] Preparation of two-dimensional topological materials: 6 mmol of 1,3,5-tribromobenzene, 9 mmol of terephthalic acid and 300 mL of solvent DMF were stirred at room temperature to fully dissolve the raw materials of each component, and then 36 mmol of K 2 CO 3 Add to the mixed system, add 0.3mmol catalyst Pd(PhCN) under the condition of nitrogen protection 2 Cl 2 , pumping and exchanging air 3 times, after fully removing the air in the reaction system, react at 80°C for 12h, then raise the temperature to 120°C for 48h, after the reaction is completed, cool the reaction system down to room temperature, add water to quench, and filter with suction. After washing with ethanol and water, the filter cake was thoroughly stirred and washed in tetrahydrofuran, methanol, water and dichloromethane at 60°C, and dried in vacuum at 120°C to obtain a two-dimensional topological material (referred to as POF-Aa).

[0125] Preparation of porous organic materials: FeCl 3 As a Lewis acid ...

Embodiment 2

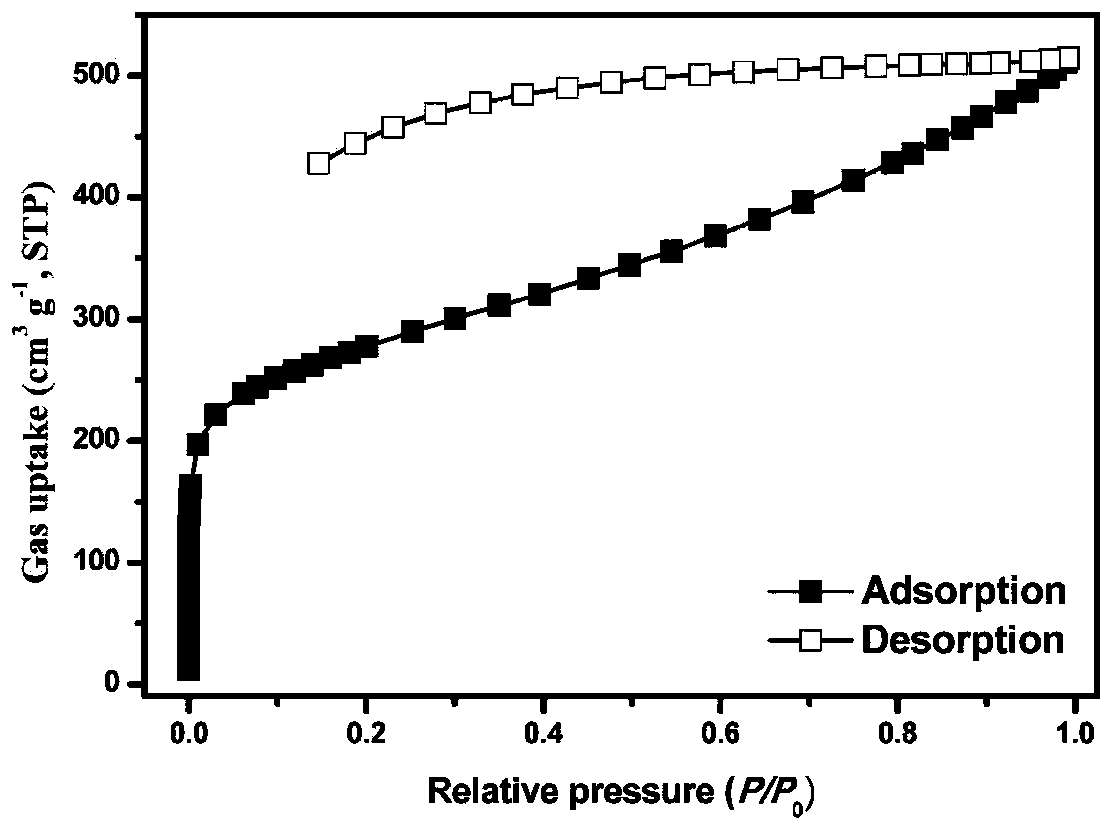

[0127] The two-dimensional topological material POF-Aa was prepared according to the method in Example 1.

[0128] Preparation of porous organic materials: AlCl 3 It is a Lewis acid catalyst, and dichloromethane is used as an external linking agent and solvent. Disperse 1.87g of POF-Aa in 200mL of dichloromethane solvent, stir well under nitrogen protection conditions to disperse, and then add 7.5mmol of catalyst to the reaction system , stirred at room temperature for 0.25h, then raised the temperature to 45°C for 1h, then raised the temperature to 80°C for 16h, after the reaction was completed, the reaction system was lowered to room temperature, quenched with hydrochloric acid aqueous solution, suction filtered, and rinsed with a large amount of ethanol and water. Subsequently, the filter cake was thoroughly stirred and washed in tetrahydrofuran, methanol, water and dichloromethane at 60°C, and finally extracted with methanol to remove trace impurities, and dried in vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com