Polyamide composition, method for producing same, and molded article

A polyamide composition and polyamide technology, applied in the field of polyamide composition and its manufacture and molded products, can solve problems such as adverse effects on mechanical properties, and achieve good long-term heat resistance and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0369] Hereinafter, the present invention will be described in detail with reference to specific examples and comparative examples, but the present invention is not limited to the following examples.

[0370] Hereinafter, each constituent component of the polyamide composition used in this Example and a comparative example is demonstrated.

[0371]

[0372] [(A) Aliphatic polyamide]

[0373] A-1: Polyamide 66

[0374] A-2: polyamide 6 (manufactured by Ube Industries, model: SF1013A, molecular weight: 33000)

[0375] [(B) Semi-aromatic polyamide]

[0376] B-1: Polyamide 6I

[0377] B-2: Polyamide 6I / 6T (manufactured by EMS Co., model: G21, content of isophthalic acid units in all dicarboxylic acid units: 70 mol%, molecular weight: 27000)

[0378] B-3: Polyamide MXD6 (made in Toyobo Co., Ltd., brand name: Toyobo nylon, T-600)

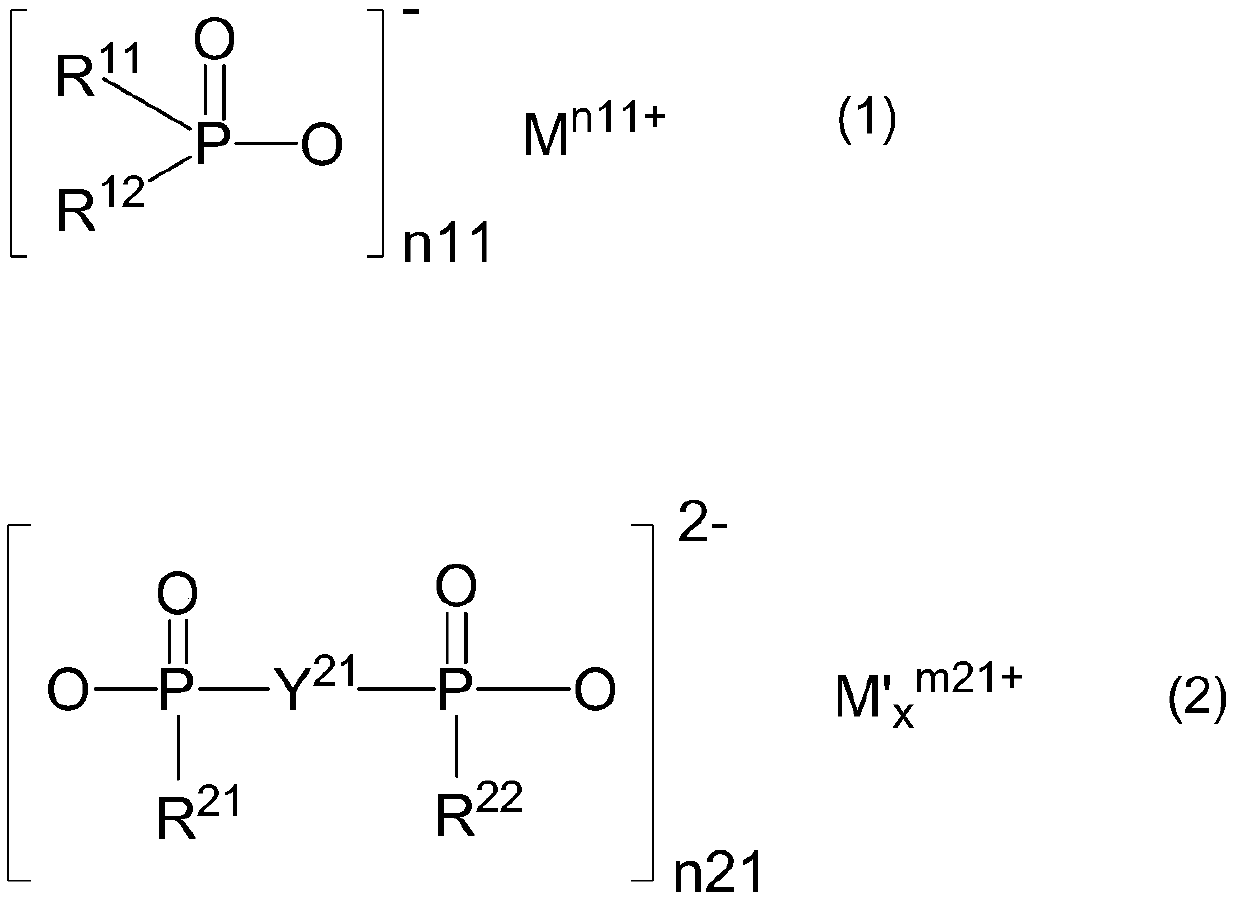

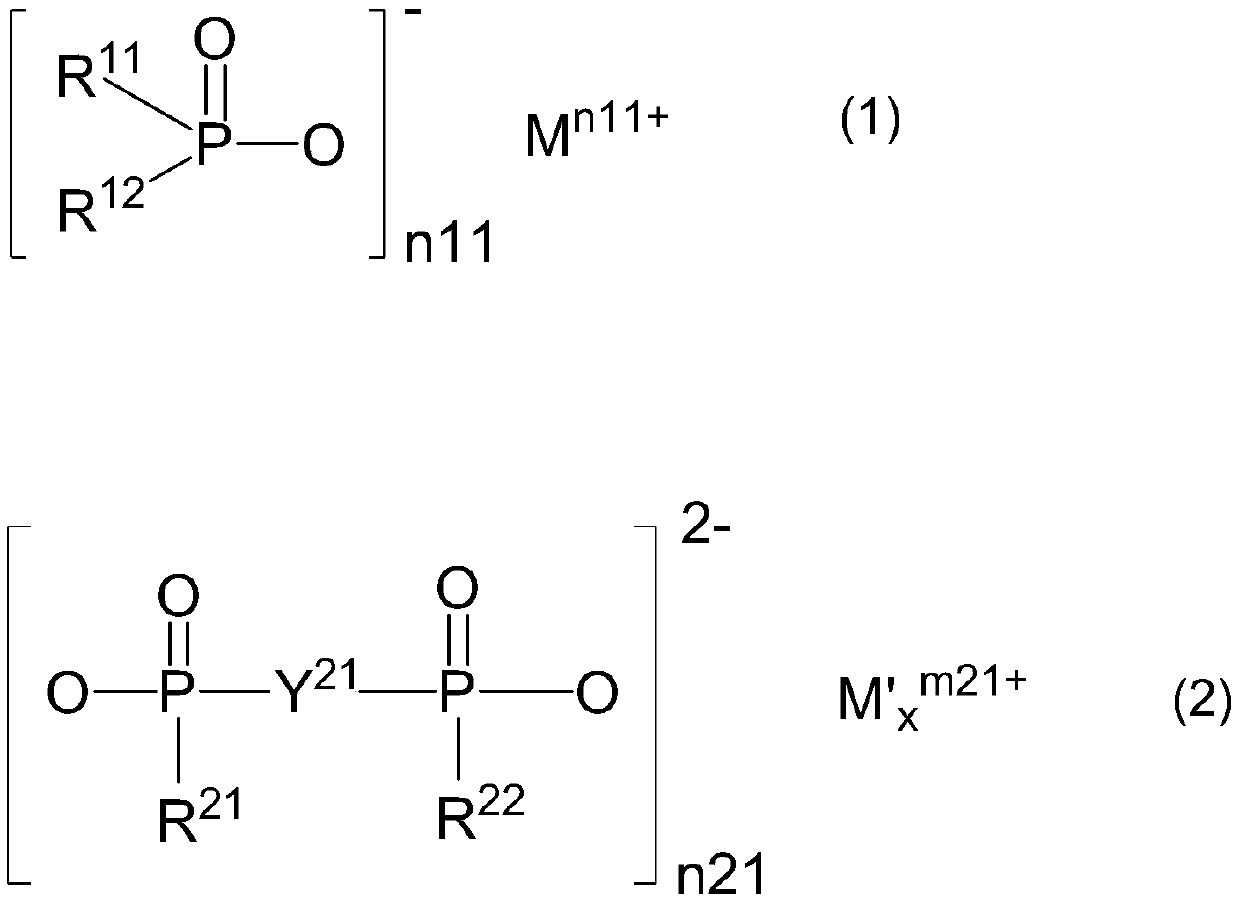

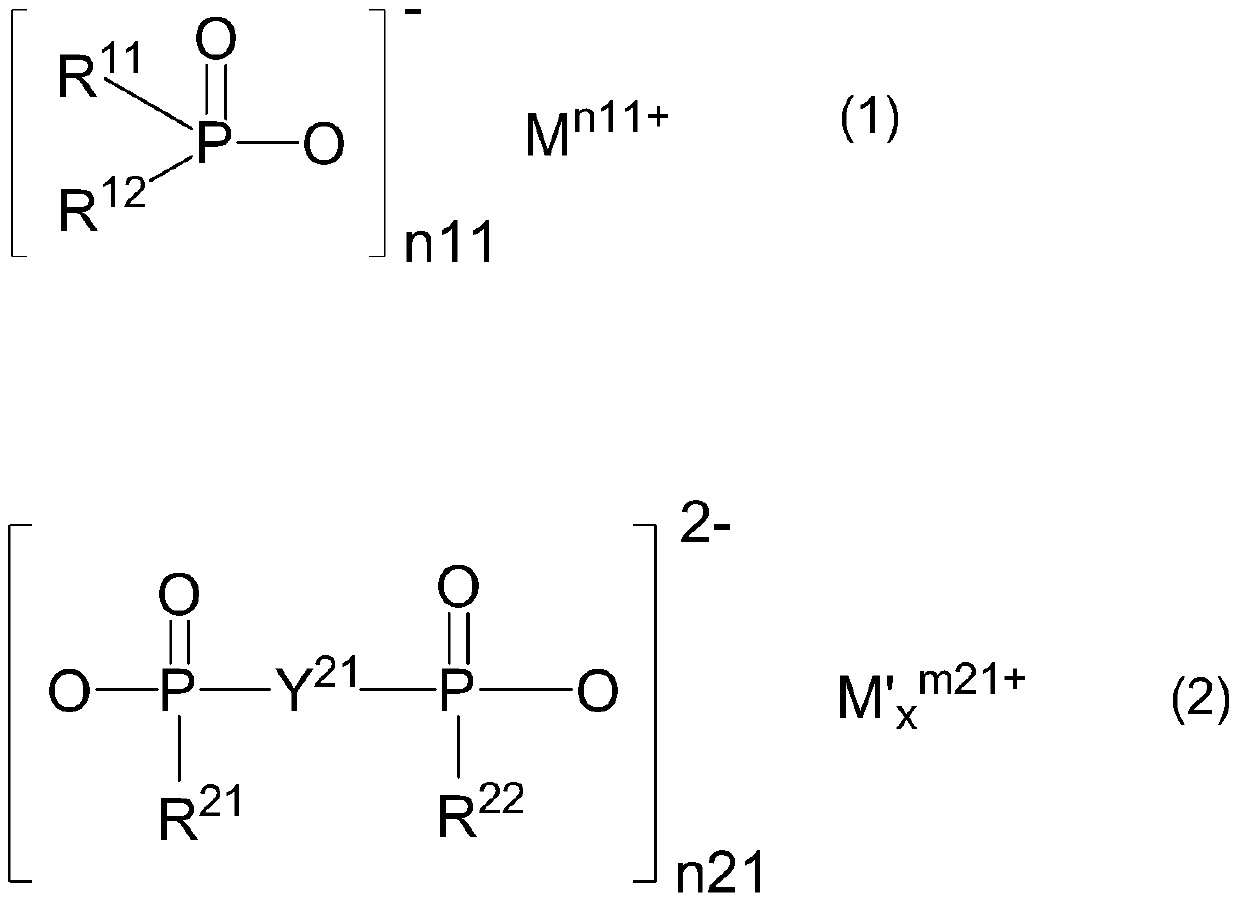

[0379] [(C) Phosphinates]

[0380] C-1: Phosphinate-based flame retardant aluminum diethylphosphinate (manufactured by Clariant, trade name: "Exo...

Synthetic example 1

[0400] [Synthesis Example 1] Synthesis of Aliphatic Polyamide A-1 (Polyamide 66)

[0401] The polymerization reaction of polyamide was implemented by the "hot-melt polymerization method" as follows.

[0402] First, 1,500 g of an equimolar salt of adipic acid and hexamethylenediamine was dissolved in 1,500 g of distilled water to prepare an equimolar 50 mass % homogeneous aqueous solution of the raw material monomers. This aqueous solution was poured into an autoclave having an internal volume of 5.4 L, and replaced with nitrogen. Next, while stirring at a temperature of about 110° C. to about 150° C., water vapor was gradually discharged and concentrated to a solution concentration of 70% by mass. Next, the internal temperature was raised to 220°C. At this time, the pressure of the autoclave was increased to 1.8 MPa. This state was maintained for 1 hour until the internal temperature reached 245° C., and the reaction was carried out for 1 hour while slowly discharging water...

Synthetic example 2

[0404] [Synthesis Example 2] Synthesis of Semiaromatic Polyamide B-1 (Polyamide 6I)

[0405] Polyamide polymerization was carried out by the "hot melt polymerization method" as described above.

[0406] First, 1,500 g of an equimolar salt of isophthalic acid and hexamethylenediamine, and 1.5 mol% of adipic acid in excess relative to the entire equimolar salt component, and 0.5 mol% of acetic acid were dissolved in 1,500 g of distilled water, thereby An equimolar 50% by mass homogeneous aqueous solution of the raw material monomers was prepared. Next, while stirring at a temperature of about 110° C. to about 150° C., water vapor was gradually discharged and concentrated to a solution concentration of 70% by mass. Next, the internal temperature was raised to 220°C. At this time, the pressure of the autoclave was increased to 1.8 MPa. This state was maintained for 1 hour until the internal temperature reached 245° C., and the reaction was carried out for 1 hour while slowly di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com