Coating for automobile engine hood model and preparation method

A technology for hoods and automobiles, applied in anti-fouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of easy breeding of bacteria, poor bonding force, paint peeling, etc., and achieve good sterilization effect, The effect of improving adhesion and enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

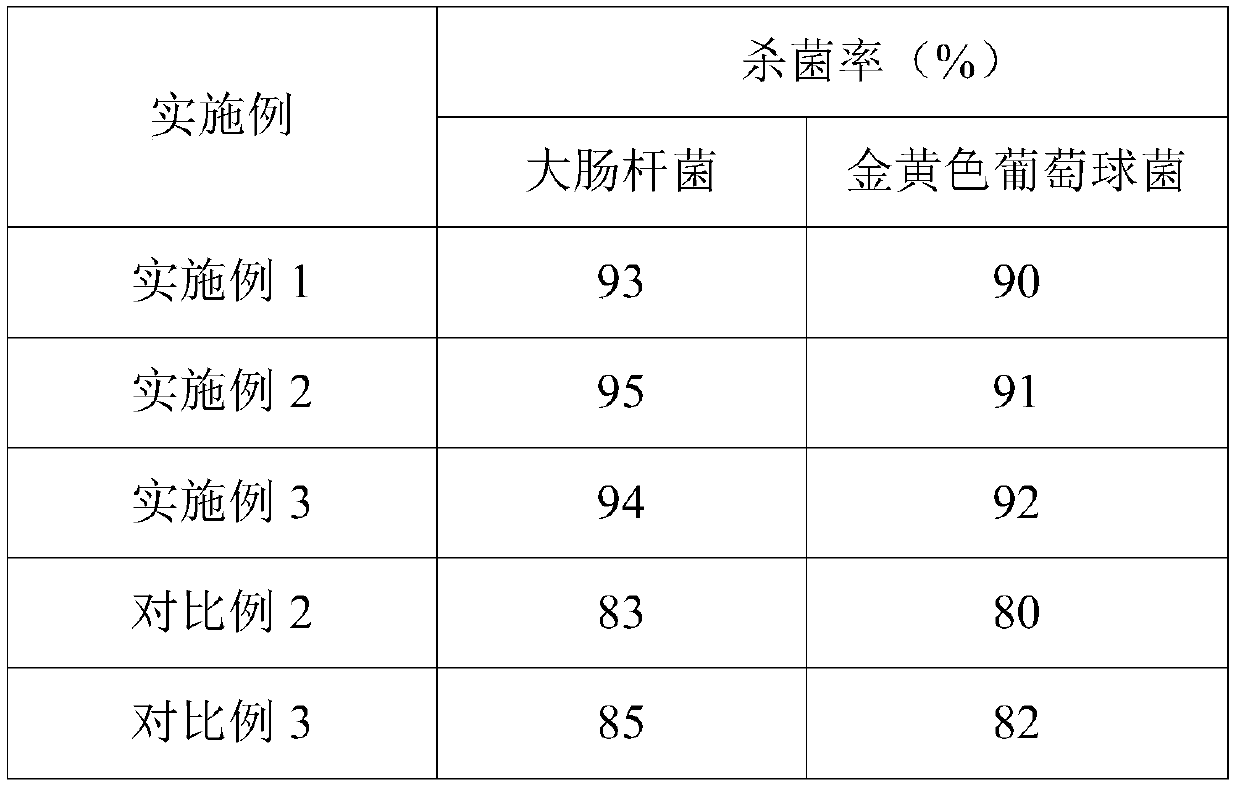

Examples

Embodiment 1

[0023] A kind of coating for automobile hood model, comprises following components by weight: 30 parts of styrene-acrylic emulsion, 20 parts of water, 2 parts of kaolin, 3 parts of aluminum powder, 5 parts of aluminum oxide, 1 part of Zirconium dioxide, 0.5 parts of fluorosilicate, 0.5 parts of nano silver, and 0.5 parts of phytobicides.

[0024] Among them, the preparation method of the plant fungicide is: after pulverizing privet leaves, vines and autumn maple, adding cellulase for enzymolysis, then placing the enzymatic hydrolyzate in a closed container, and then feeding water vapor to make the pressure in the closed container 2Mpa , keep it for 0.5h, then release the pressure to 10pa within 8s, continue to introduce water vapor to make the pressure in the airtight container 0.5Mpa, keep it for 10min, then release the pressure to 5pa within 5s, keep it for 1min, take it out to get the plant fungicide. The mass ratio of privet leaf, vine vine, autumn maple and cellulase is 2...

Embodiment 2

[0031] A kind of coating for automobile hood model, comprises following components by weight: 35 parts of styrene-acrylic emulsion, 25 parts of water, 3 parts of kaolin, 4 parts of aluminum powder, 8 parts of aluminum oxide, 2 parts of Zirconium dioxide, 0.8 parts of fluorosilicate, 0.8 parts of nano silver, and 0.8 parts of phytobicides.

[0032] Among them, the preparation method of the plant fungicide is as follows: after pulverizing privet leaves, vines and autumn maple, adding cellulase for enzymolysis, then placing the enzymatic hydrolyzate in an airtight container, and then feeding water vapor to make the pressure in the airtight container 3Mpa , keep it for 0.8h, then release the pressure to 10pa within 8s, continue to pass water vapor to make the pressure in the airtight container 0.8Mpa, keep it for 10min, then release the pressure to 5pa within 5s, keep it for 1min, take it out to get the plant fungicide. The mass ratio of privet leaf, vine vine, autumn maple and ce...

Embodiment 3

[0039] A kind of coating for automobile hood model, comprises following components by weight: 40 parts of styrene-acrylic emulsion, 30 parts of water, 5 parts of kaolin, 6 parts of aluminum powder, 10 parts of aluminum oxide, 3 parts of Zirconium dioxide, 1 part of fluorosilicate, 1 part of nano silver, 1 part of phytoncide.

[0040]Among them, the preparation method of the plant fungicide is as follows: after pulverizing privet leaves, vines and autumn maple, adding cellulase for enzymolysis, then placing the enzymatic hydrolyzate in an airtight container, and then feeding water vapor to make the pressure in the airtight container 3Mpa , keep it for 1h, then release the pressure to 10pa within 8s, continue to introduce water vapor to make the pressure in the airtight container 1Mpa, keep it for 20min, then release the pressure to 5pa within 5s, keep it for 1min, take it out to get the plant fungicide. The mass ratio of privet leaf, vine vine, autumn maple and cellulase is 3:2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com