Immobilized enzyme as well as preparation method and application thereof

A technology of immobilized enzymes and reductases, which is applied in the direction of immobilized enzymes, biochemical equipment and methods, fixed on/in organic carriers, etc., can solve the problems of difficult recycling of enzymes, achieve stable immobilization effects, and improve The effect of recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

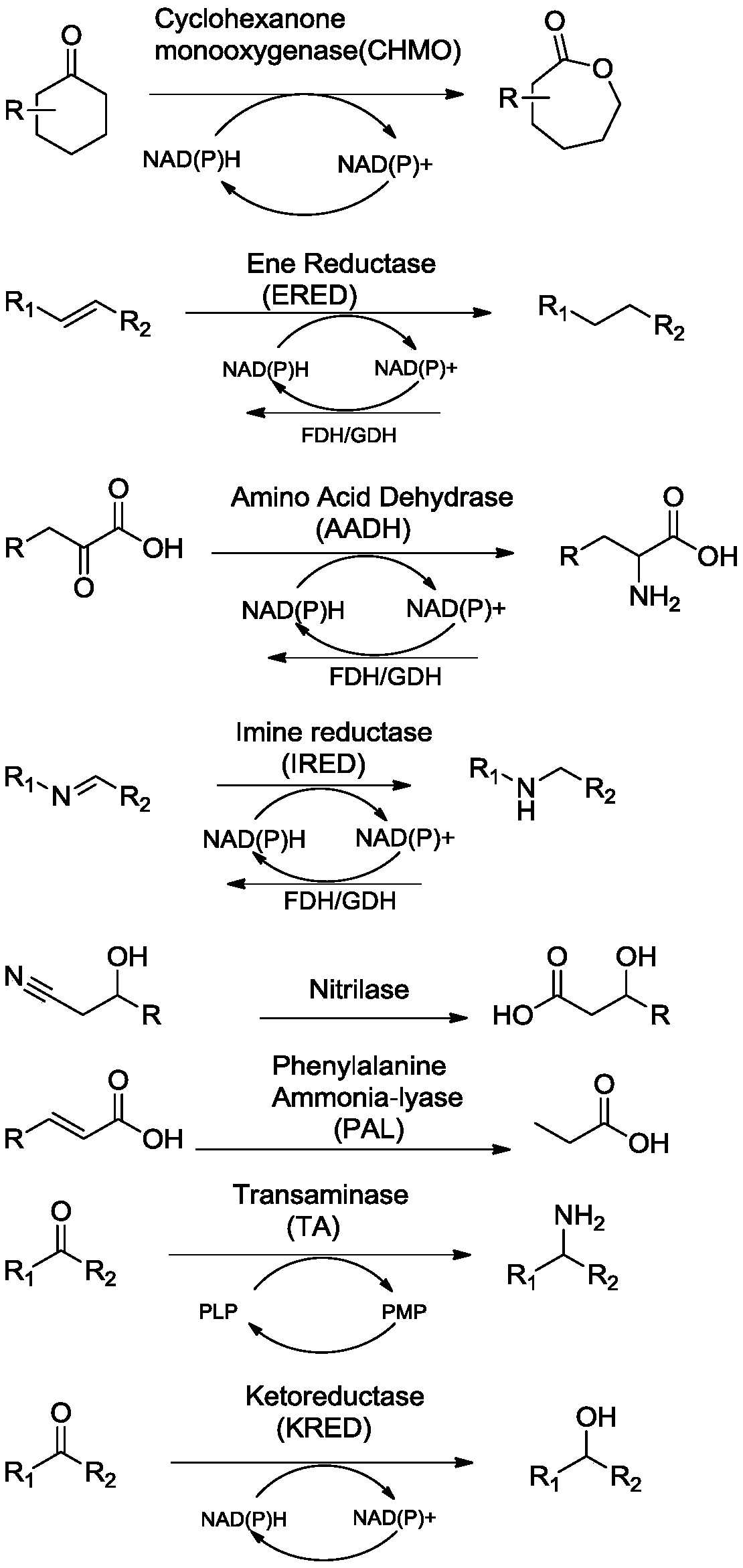

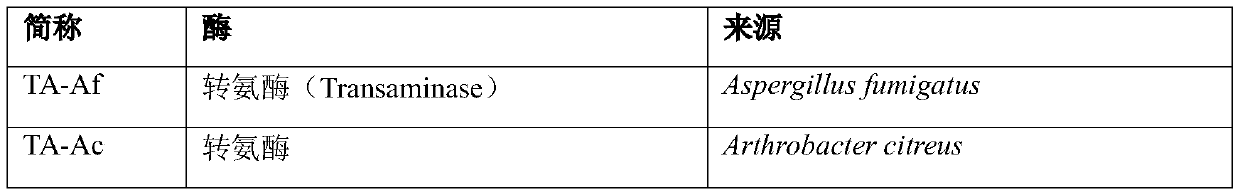

[0050] In the second typical embodiment of the present application, a method for preparing immobilized enzymes is provided, the preparation method comprising: pre-treating the cross-linking agent with a polymer to obtain a processed cross-linking agent; Amino resin carrier is modified by reagent to obtain modified carrier; enzyme is fixed on the modified carrier to obtain immobilized enzyme; enzyme is selected from transaminase, ketoreductase, monooxygenase, ammonia lyase, ene reductase, imine reduction Any one of enzymes, amino acid dehydrogenases, and nitrilases.

[0051] The preparation method of the present application pre-treats the cross-linking agent with a polymer, so that the cross-linking agent has more network structure, and then uses the cross-linking agent with more network structure to modify the amino resin carrier , so that the carrier also has more network structures, so when the enzyme is immobilized on the modified carrier, the immobilization effect on the e...

Embodiment 1

[0084] Example 1: Immobilized transaminase

[0085] Take 1 g of amino resin, wash it with 20 mM phosphate buffer solution (referred to as PB, pH7.0) and set aside.

[0086]Add 160 μL of glutaraldehyde (50% aqueous solution) to 4 mL of PB buffer (20 mM, pH 7.0), and add an appropriate ratio of PEG or PEI. After incubating at room temperature for 30-60 min, add the above-mentioned amino resin to the solution, followed by 20 Incubate at -25°C for 1-2h. The modified amino resin was obtained after filtration, and then 4 mL of enzyme solution (20-25 mg / mL protein, including the main enzyme and its corresponding coenzyme) was added to the modified amino resin, and then incubated at 20° C. for 16-24 h. Finally, wash 3 times with 20 mM PB (pH 8.0 containing 0.5M NaCl).

[0087] Immobilized transaminase activity and reusability test:

[0088]

[0089] In a 10mL reaction bottle, add 0.3mL MeOH, dissolve 0.1g of main material 1 or main material 2, add 4eq isopropylamine hydrochlorid...

Embodiment 2

[0094] Embodiment 2: Conversion rate and reutilization test of immobilized ketoreductases (ketoreductases)

[0095] The immobilization method is the same as in Example 1

[0096] Immobilized enzyme activity and reusability detection:

[0097]

[0098] In a 10mL reaction flask, add 0.5mL isopropanol (IPA), dissolve 0.1g of the main material 3 or 4, and add 0.5mL0.1M PB 7.0 and 1-10mg NAD+, then add 0.05g enzyme powder or by 0.1- 0.3g of immobilized enzyme prepared by enzyme powder, stirred at 30°C for 16-20h. The conversion rate of the system was detected by GC. After each round of reaction, the immobilized enzyme was separated and reused in the next round of reaction, and the number of reuse was investigated. The response data is as follows:

[0099] Table 8:

[0100]

[0101]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com