Modified low-ester pectin emulsion and preparation method thereof

A low-ester pectin and modified technology, applied in the field of food processing, can solve problems such as the decline of antioxidant activity, and achieve the effects of improving emulsifying performance, facilitating large-scale industrial production, and having good water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

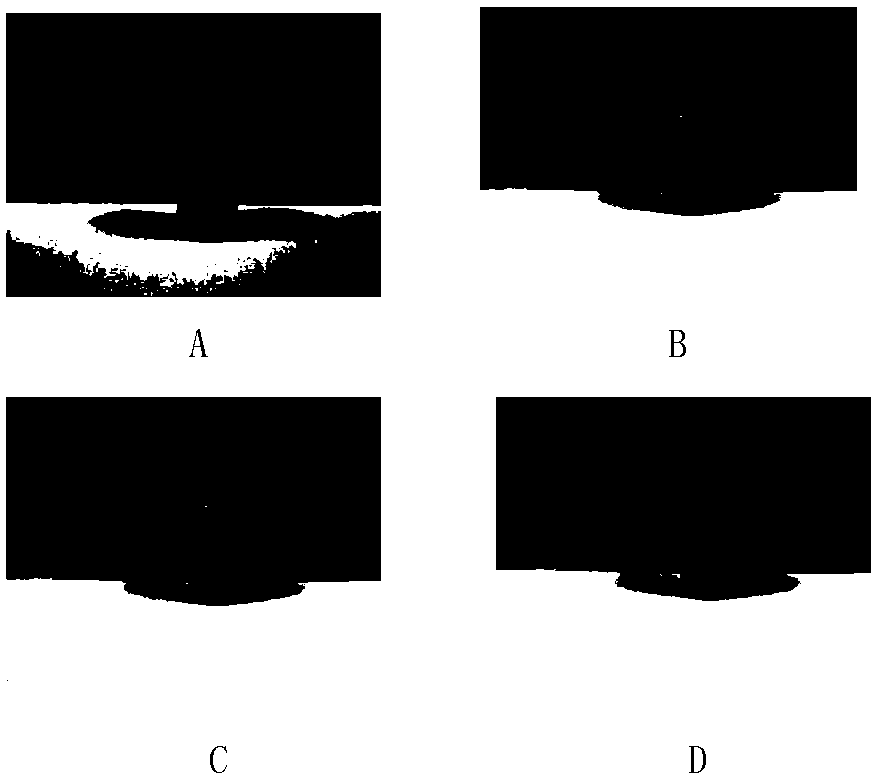

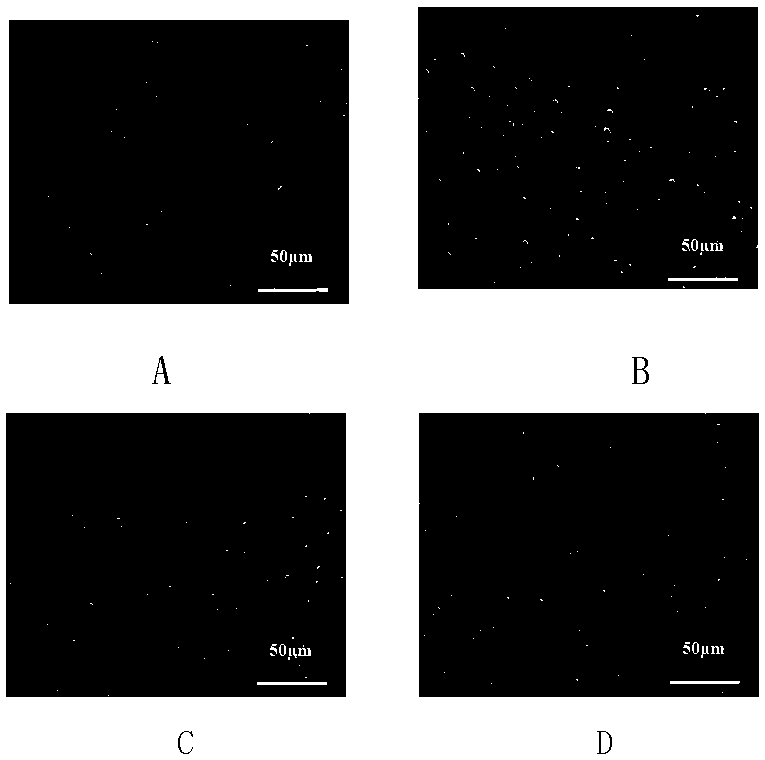

Image

Examples

Embodiment 1

[0044] A kind of preparation operation step of modified low-ester pectin emulsion is as follows:

[0045] Step 1: Preparation of oligopeptides

[0046] Prepare a 5 g / L isolated soybean protein powder solution and place it in an enzymatic hydrolysis tank, adjust the pH value to 7.0 with 0.1 mol / L NaOH solution, preheat to 40 °C, and add 150 U of pancreatic Protease, under the conditions of temperature 45±1 ℃, rotation speed 150 r / min, and ultrasonic power 200 W, enzymolysis was carried out for 2.5 h to obtain enzymatic hydrolysis solution; The primary retentate returns to the enzymolysis tank, the primary permeate passes through the secondary ultrafiltration membrane system with a molecular weight cut-off of 2000 kDa, the secondary retentate returns to the enzymolysis tank, and the secondary permeate passes through the nanofiltration membrane system to collect The retentate treated by the nanofiltration membrane system is placed in a vacuum dryer at 65 °C and dried until the m...

Embodiment 2

[0055] A kind of preparation operation step of modified low-ester pectin emulsion is as follows:

[0056] Step 1: Preparation of oligopeptides

[0057] Prepare a 6 g / L chickpea protein powder solution and place it in an enzymatic hydrolysis tank, adjust the pH value to 7.5 with 0.1 mol / L NaOH, preheat to 45 °C, and add 200 U of Trypsin was enzymolyzed for 2.0 h at a temperature of 45±1 °C, a rotational speed of 180 r / min, and an ultrasonic power of 250 W to obtain an enzymatic hydrolyzate; The primary retentate returns to the enzymatic hydrolysis tank, the primary permeate passes through the secondary ultrafiltration membrane system with a molecular weight cut-off of 2000 kDa, the secondary retentate returns to the enzymatic hydrolysis tank, and the secondary permeate passes through the nanofiltration membrane system. Collect the retentate treated by the nanofiltration membrane system and dry it in a vacuum dryer at 70 °C until the moisture content is lower than 7.8%, to obta...

Embodiment 3

[0066] A kind of preparation operation step of modified low-ester pectin emulsion is as follows:

[0067] Step 1: Preparation of oligopeptides

[0068] Prepare 5.5 g / L pea protein powder solution and place it in an enzymatic hydrolysis tank, adjust the pH value to 7.2 with 0.1 mol / L NaOH solution, preheat to 42 °C, add 180 U of trypsin per liter of pea protein powder solution, Under the conditions of temperature 45±1 ℃, rotation speed 160 r / min, and ultrasonic power 220 W, the enzymolysis solution was obtained for 2.2 h; The liquid returns to the enzymolysis tank, the primary permeate passes through the secondary ultrafiltration membrane system with a molecular weight cut-off of 2000 kDa, the secondary retentate returns to the enzymolysis tank, and the secondary permeate passes through the nanofiltration membrane system to collect the supernatant. The retentate treated by the filter membrane system is dried in a vacuum dryer at 70°C until the moisture content is lower than 7....

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com