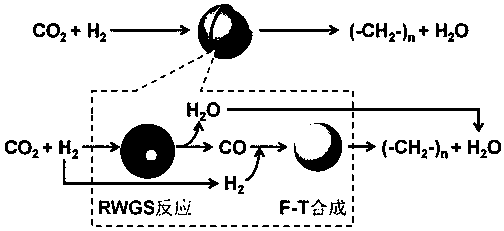

Preparation method of bifunctional core-shell catalyst for preparing aviation kerosene through carbon dioxide hydrogenation

A technology of carbon dioxide and aviation kerosene, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of small pore volume, increase of initial P content, specific surface area minor issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

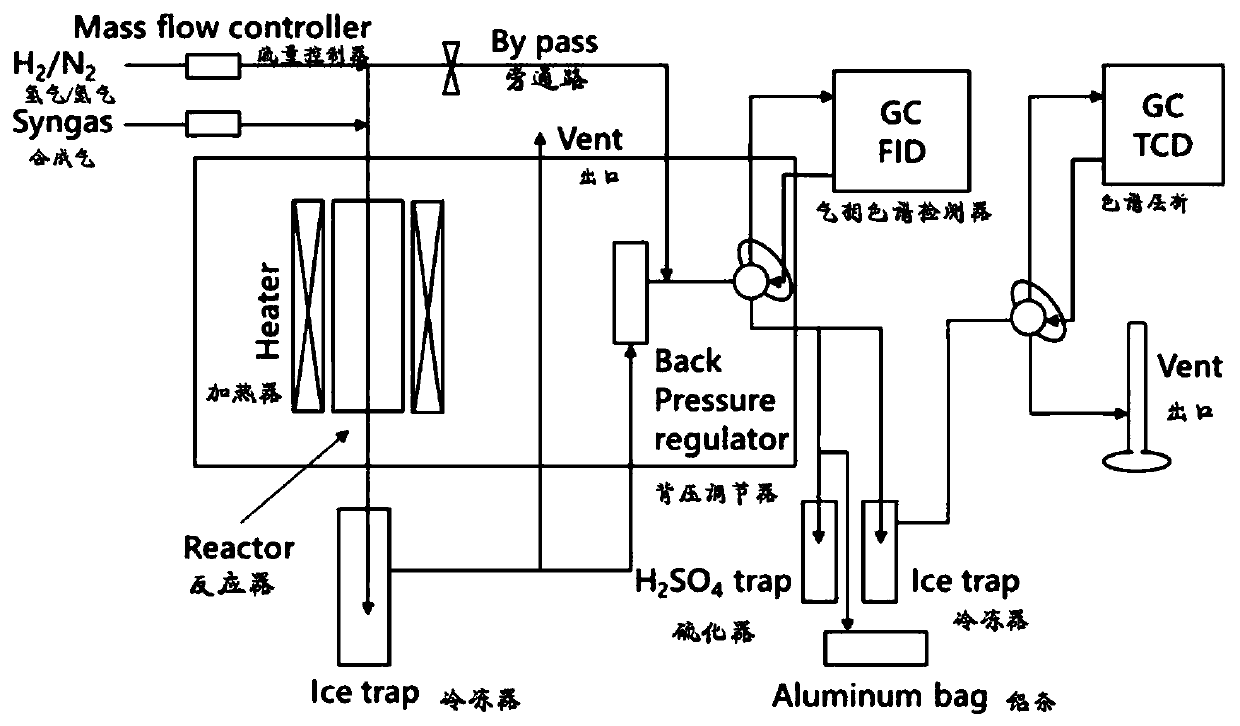

Method used

Image

Examples

Embodiment 1

[0040] A preparation of a dual-functional core-shell catalyst for hydrogenation of carbon dioxide to prepare aviation kerosene, the specific operation steps are as follows:

[0041] a. Synthesis of Cu-Fe / SiO 2 Catalytic core

[0042] (1) Carrier pretreatment:

[0043] SiO 2 The pellets were placed in deionized water and cleaned with ultrasonic power of 100W for 30 minutes. After cleaning, they were dried in a 200K oven for 10 hours, roasted in a muffle furnace at 750K for 5 hours, and then cooled to room temperature to obtain pretreated SiO 2 Carrier pellets, and store in a desiccator for later use;

[0044] (2) Preparation of catalyst by impregnation method:

[0045] Weigh 5 grams of ferric nitrate and 2 grams of copper nitrate, dissolve them in 20 grams of deionized water, configure a nitrate mixture solution, and then weigh 5 grams of pretreated SiO prepared in step (1) 2 The carrier pellets were put into the nitrate mixture solution, fully impregnated, and rotated to ...

Embodiment 2

[0059] A preparation of a dual-functional core-shell catalyst for hydrogenation of carbon dioxide to prepare aviation kerosene, the specific operation steps are as follows:

[0060] a. Synthesis of Cu-Fe / SiO 2 Catalytic core

[0061] (1) Carrier pretreatment:

[0062] SiO 2 The pellets were placed in deionized water and cleaned with ultrasonic power of 100W for 60 minutes. After cleaning, they were dried in a 400K oven for 12 hours, roasted in a muffle furnace at 850K for 7 hours, and then cooled to room temperature to obtain pretreated SiO 2 Carrier pellets, and store in a desiccator for later use;

[0063] (2) Preparation of catalyst by impregnation method:

[0064] Weigh 7 grams of ferric nitrate and 3 grams of copper nitrate, dissolve them in 30 grams of deionized water, configure a nitrate mixture solution, and then weigh 15 grams of pretreated SiO prepared in step (1) 2 Put the carrier pellets into the nitrate mixture solution, fully impregnate them, and rotate them...

Embodiment 3

[0078] A preparation of a dual-functional core-shell catalyst for hydrogenation of carbon dioxide to prepare aviation kerosene, the specific operation steps are as follows:

[0079] a. Synthesis of Cu-Fe / SiO 2 Catalytic core

[0080] (1) Carrier pretreatment:

[0081] SiO 2 The pellets were placed in deionized water and cleaned with ultrasonic power of 100W for 45 minutes. After cleaning, they were dried in a 300K oven for 1 hour, roasted in a muffle furnace at 800K for 6 hours, and then cooled to room temperature to obtain pretreated SiO 2 Carrier pellets, and store in a desiccator for later use;

[0082] (2) Preparation of catalyst by impregnation method:

[0083] Weigh 6 grams of ferric nitrate and 2.5 grams of copper nitrate, dissolve them in 25 grams of deionized water, configure a nitrate mixture solution, and then weigh 10 grams of pretreated SiO prepared in step (1) 2 Put the carrier pellets into the nitrate mixture solution, fully impregnate them, and rotate them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com