Activated sludge cracking and separating integrated device and process

A technology of activated sludge and plasma, applied in sludge treatment, pyrolysis sludge treatment, electrochemical sludge treatment, etc., can solve the problems of limited recovery rate, long reaction time, unstable performance, etc., and achieve the reduction of gas-solid Effects of load separation, high chain reaction rate, and low energy consumption for reaction triggering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can understand.

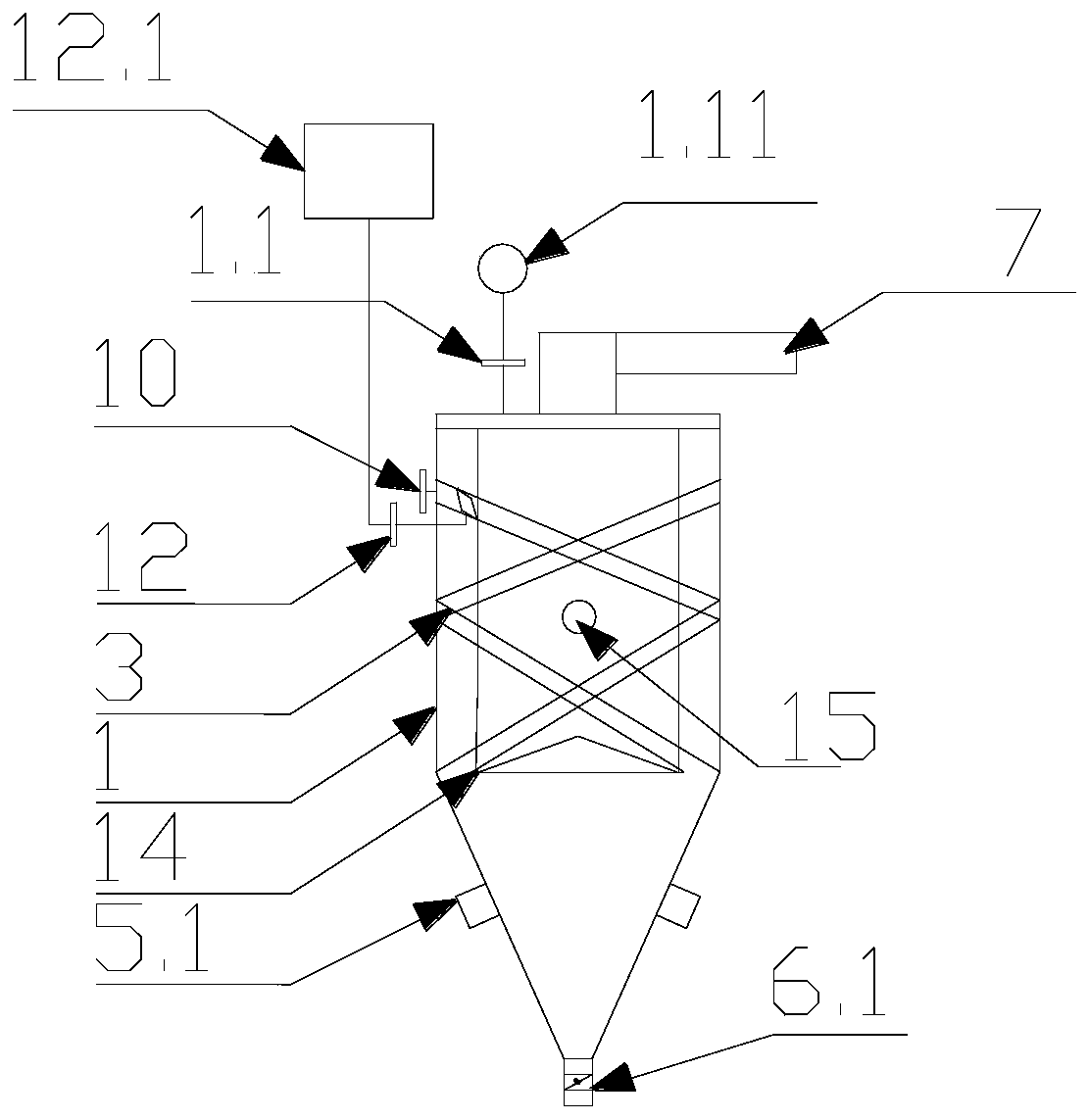

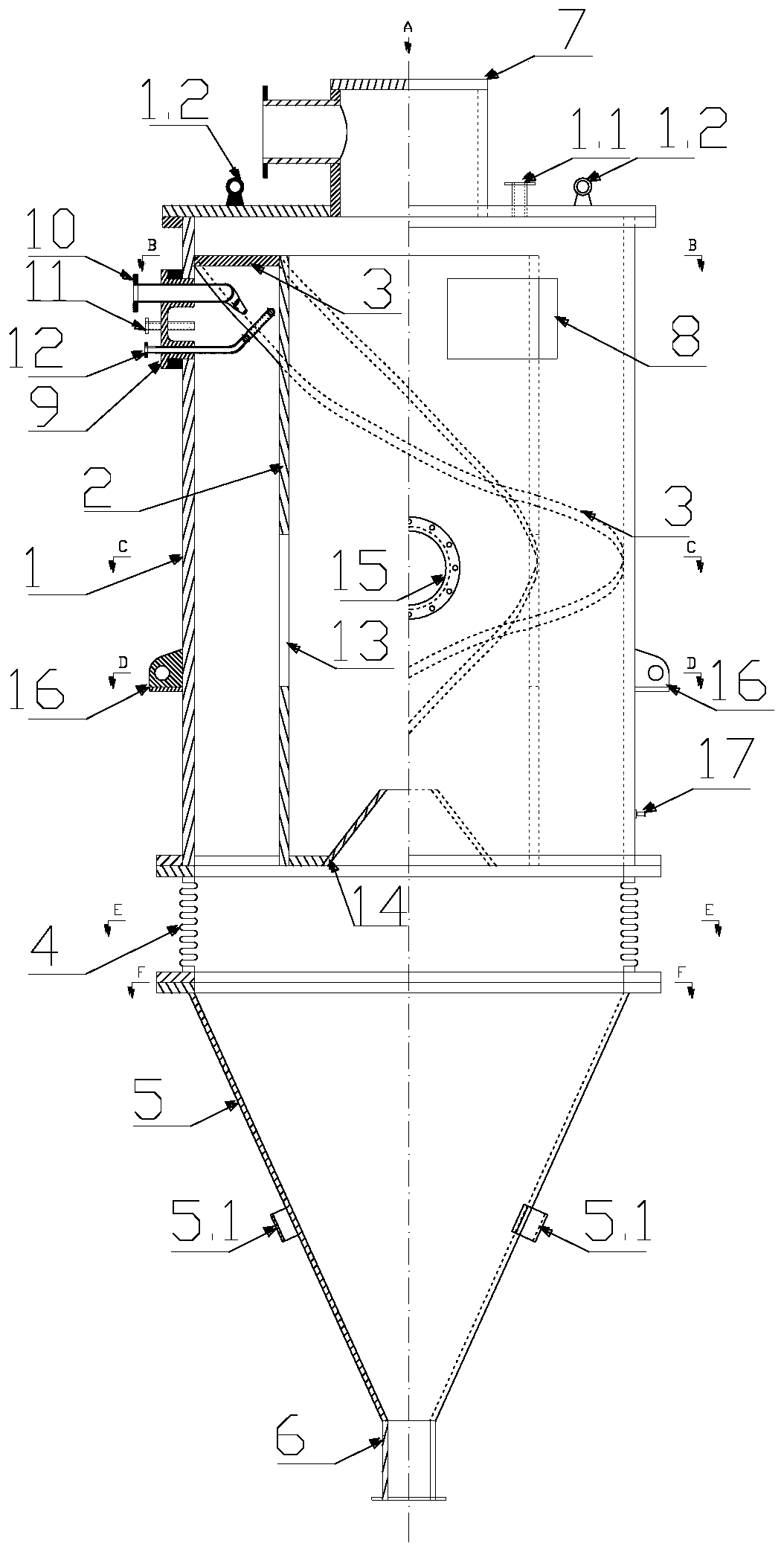

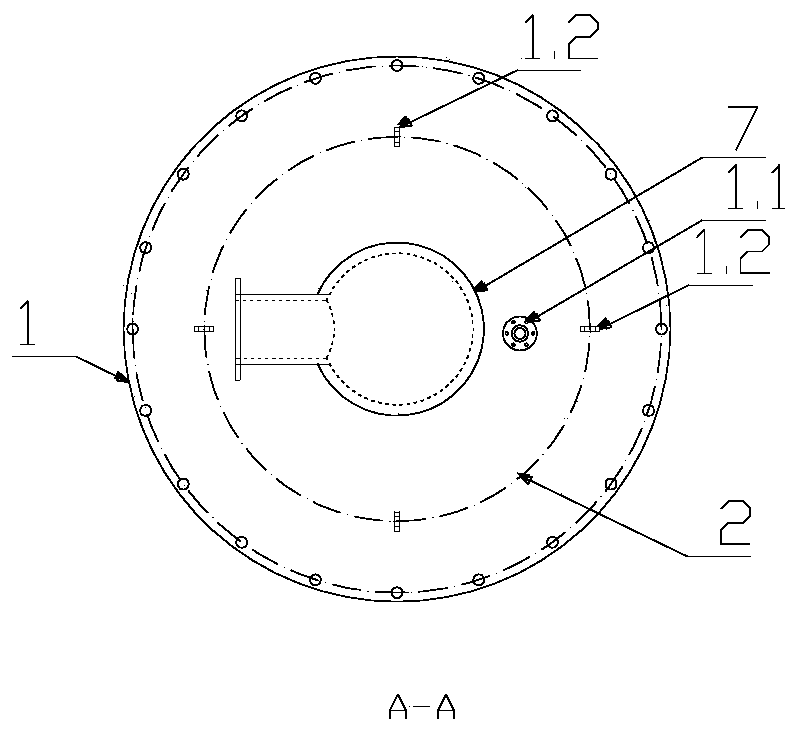

[0051] Such as Figure 1-12 The shown activated sludge cracking and separation integrated device includes an external shell barrel 1 and an internal rectifying barrel 2, and three spiral deflectors 3 are arranged symmetrically from top to bottom between the shell barrel 1 and the rectifying barrel 2; The bellows 4 is connected to the lower cover of the shell barrel 1, the hopper 5 is connected to the lower part of the bellows 4, and two vibrator brackets 5.1 are symmetrically arranged on the outer wall of the hopper 5;

[0052] A discharge pipe 6 is connected below the hopper 5; a discharge valve 6.1 is arranged on the discharge pipe 6; an inverted L-shaped exhaust pipe 7 is arranged in the center of the top cover of the shell barrel 1, and four symmetrically arranged on the upper cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com