Ampoule bottle low-temperature heat-sealing method

An ampoule bottle, melting and sealing technology, applied in the field of low temperature melting and sealing of ampoules, can solve the problems affecting the quality, concentration and solvent volatilization of the standard solution in the bottle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

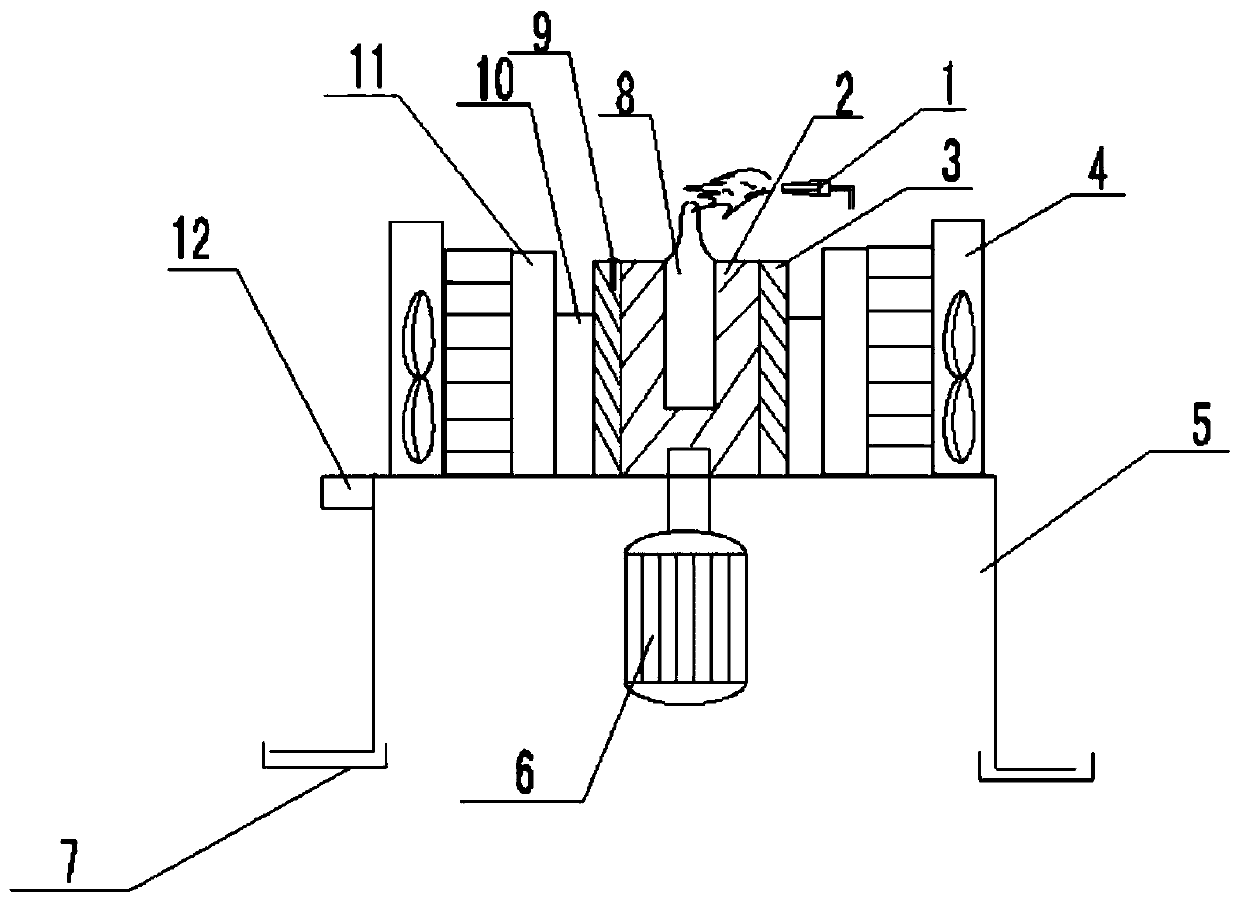

[0022] The invention discloses a method for low temperature melting and sealing of ampoule bottles. The ampoule bottles are sealed and melted under the condition of 5-10 DEG C. The solvent of the standard solution contained in the ampoule bottles is carbon disulfide. like figure 1 As shown, the low-temperature melting and sealing device includes a brass sleeve 2 with an ampoule shape adapted to the cavity inside, the copper sleeve 3 is sleeved on the outside of the brass sleeve 2, a thermometer 9 is arranged in the red copper sleeve 3, and the outside of the copper sleeve 3 is provided with a thermometer 9. Connect the semiconductor refrigerating sheet 10, the height of the semiconductor refrigerating sheet 10 is slightly lower than the copper sleeve 3, to ensure the safety of melting and sealing, and prevent the bottle body from bursting; The copper sleeve 3, the semiconductor refrigerating sheet 10, the aluminum heat sink 11, and the exhaust fan 4 are all arranged on the bra...

Embodiment 2

[0025] The invention discloses a method for low temperature melting and sealing of ampoule bottles. The ampoule bottles are sealed and melted under the condition of 10-15 DEG C. The solvent of the standard solution contained in the ampoule bottles is methanol. The low-temperature sealing device is the same as that of Example 1.

[0026] During work, the ampoule bottle 8 to be sealed containing the standard solution is placed in the brass sleeve 2, and the cylindrical bottle body of the lower half of the ampoule bottle 8 is placed in the brass sleeve 2. According to the properties of the solvent, Set the required ambient temperature to 10-15°C, adjust the cooling temperature of the semiconductor refrigeration chip 10 and the heat dissipation size of the exhaust fan 4 through the PLC system, adjust the height and position of the flame nozzle 1, ignite the flame, push the handle 12, and put the ampoule 8 on the device. Pushed to the flame, the rotating rod of the rotary motor 6 d...

Embodiment 3

[0028] A method for low-temperature melting and sealing of ampoule bottles, wherein the ampoule bottles are sealed and melted under the condition of 10-15 DEG C, wherein the solvent of the standard solution contained in the ampoule bottle is benzene. The low-temperature sealing device is the same as that of Example 1.

[0029] During work, the ampoule bottle 8 to be sealed containing the standard solution is placed in the brass sleeve 2, and the cylindrical bottle body of the lower half of the ampoule bottle 8 is placed in the brass sleeve 2. According to the nature of the solvent, Set the required ambient temperature to 10-15°C, adjust the cooling temperature of the semiconductor refrigeration chip 10 and the heat dissipation size of the exhaust fan 4 through the PLC system, adjust the height and position of the flame nozzle 1, ignite the flame, push the handle 12, and put the ampoule 8 on the device. Pushed to the flame, the rotating rod of the rotary motor 6 drives the ampo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap