Manufacturing method of single-layer TCTS relaxation-resistant coating in alkali metal gas chamber

The technology of an alkali metal gas chamber and its manufacturing method is applied in the direction of coatings and devices for coating liquid on the surface, etc., which can solve problems such as narrow application range, poor relaxation resistance, and poor coating consistency, so as to reduce the coating Difficult to make, simple and feasible to operate, ensuring consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

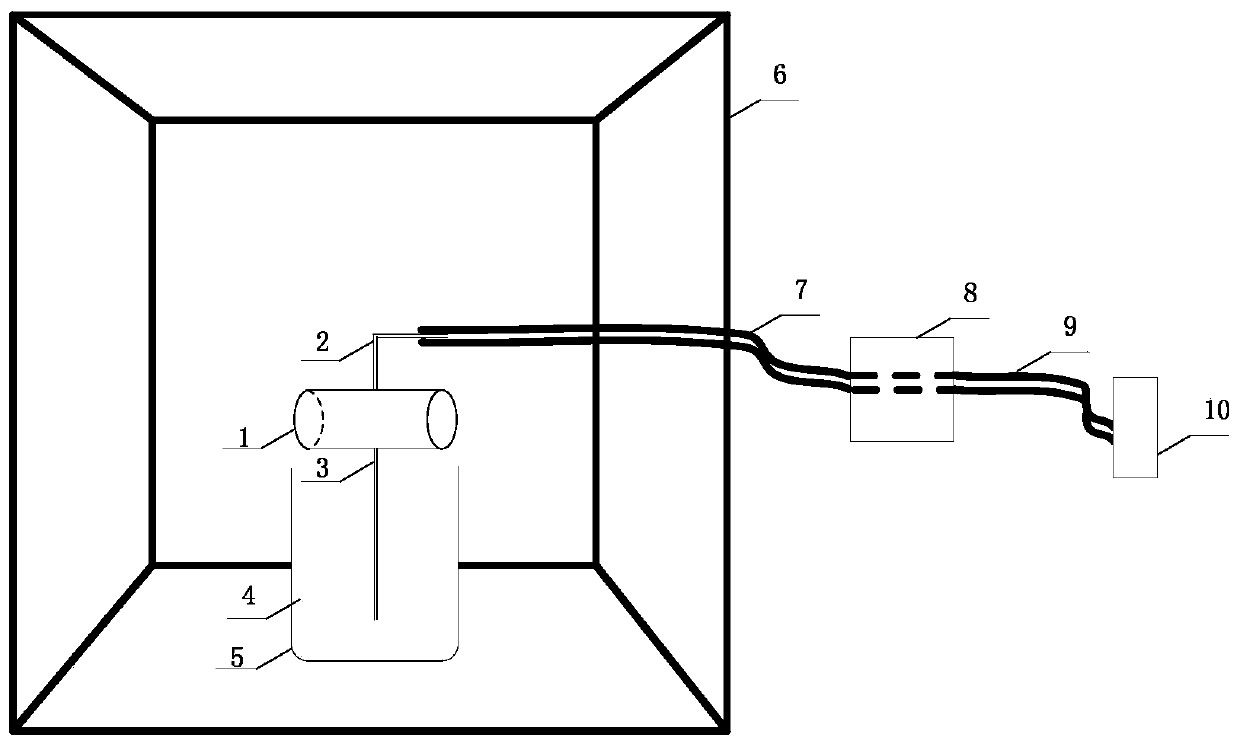

[0018] Below with the accompanying drawings ( figure 1 ) to illustrate the present invention.

[0019] figure 1 It is a schematic diagram of the device layout for implementing the method for manufacturing a single-layer TCTS anti-relaxation coating in an alkali metal gas chamber of the present invention. see figure 1As shown, a method for manufacturing a single-layer TCTS anti-relaxation coating in an alkali metal gas chamber comprises the following steps, placing the first container 5 prepared with a TCTS solution 4 and the alkali metal gas chamber 1 after hydroxylation treatment on the inner wall In the heated state, place the lower tailpipe 3 of the alkali metal gas chamber 1 in the TCTS solution 4, connect the upper tailpipe 2 of the alkali metal gas chamber 1 to the left section 7 of the silicone tube of the peristaltic pump 8 to inhale port, the right section 9 port of the silicone tube of the peristaltic pump 8 is an exhaust port, start the peristaltic pump 8 so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com