Enhancement method of porous coral aggregate

A coral and aggregate technology, which is applied in the field of porous coral aggregate reinforcement, can solve the problems of reducing the cement slurry’s cohesive force, difficulty in immersing in elongated pores, and poor operability, so as to reduce water absorption, low processing cost, and increase workability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

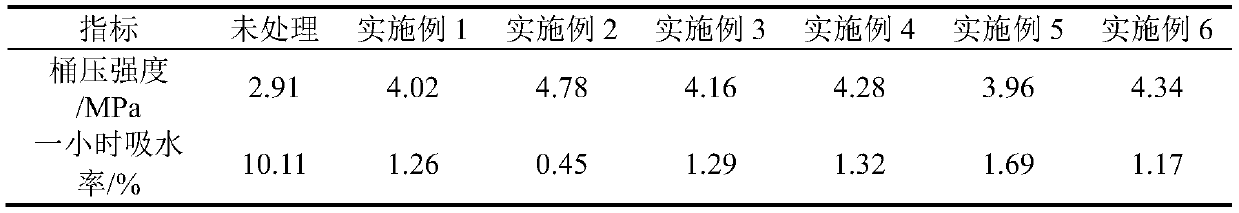

Embodiment 1

[0044] Step 1: Use a jaw crusher to crush the coral aggregates, sieve the coral aggregates with a particle size of 10mm, and dry the coral aggregates at 105°C for 24 hours; after drying, immerse the coral aggregates in water The glass modulus is 3.5 and the Baume degree is 40% in an airtight container containing sodium water glass, and at the same time, the coral aggregate is oscillated by an ultrasonic oscillator to discharge the gas in the coral aggregate; after soaking for 2 hours, the coral aggregate is sealed. Take it out of the container, wipe the surface clean, and put it into a 105°C oven for water glass dehydration treatment. After 6 hours, the dehydrated coral aggregates were taken out, soaked in saturated calcium chloride solution for 12 hours, and then taken out and placed in an 80°C oven for drying for 6 hours. Soak the coral aggregate in sodium water glass solution for 2 hours again, take it out and dry it, then soak it in saturated calcium chloride solution for ...

Embodiment 2

[0048] Step 1: a method for enhancing porous coral aggregates, using a jaw crusher to crush the coral aggregates, sieve the coral aggregates with a particle size of 10mm, and dry the coral aggregates at 105°C for 24 hours; Then, put the coral aggregates into a closed container, use a vacuum pump to extract the air in the container to 0.01 standard atmosphere, and then immerse the coral aggregates in the enhancer A in the closed container, that is, the water glass modulus is 2.5, wave Mido is 35% sodium-containing water glass; after soaking for 8-12 minutes, take out the coral aggregate from the airtight container, wipe the surface clean, and put it in an 80 ℃ oven for water glass dehydration treatment. After 6 hours, take out the dehydrated coral aggregate, put it into the enhancer B, that is, soak it in a saturated calcium chloride solution for 12 hours, take it out and put it into an 80°C oven for drying. The coral aggregates were soaked in sodium water glass solution for 2 ...

Embodiment 3

[0052] Step 1: Use a jaw crusher to crush the coral aggregates, sieve the coral aggregates with a particle size of 10mm, and dry the coral aggregates at 105 ° C for 24 hours; after drying, immerse the coral aggregates in a container. The modulus of water glass is 3, and the Baume degree is 45%. The water glass contains potassium, and at the same time, the coral aggregate is oscillated by an ultrasonic oscillator to discharge the gas in the coral aggregate; after soaking for 1.5 hours, the coral aggregate is placed in an airtight container. Take it out, wipe the surface clean, put it in a 105°C oven for water glass dehydration; take out the dehydrated coral aggregate after 7 hours, put it in the enhancer B, that is, soak it in saturated calcium chloride solution for 10 hours, take it out and put it in Dry in an oven at 80°C for 5 hours. The coral aggregate was soaked in potassium water glass solution again for 2.5 hours, taken out and dried, then soaked in saturated calcium chl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com