Method for preparing cyclohexane dimethylamine

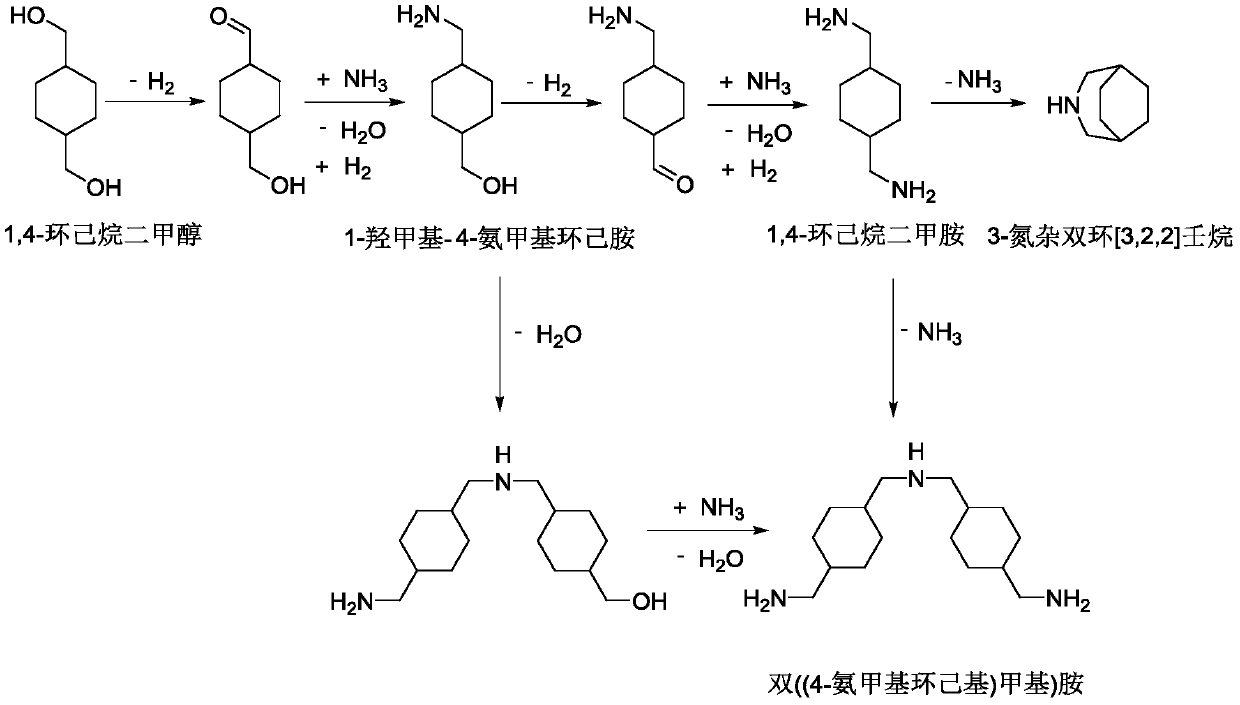

A technology of cyclohexanedimethylamine and cyclohexanedimethanol is applied in the field of preparation of cyclohexanedimethylamine and can solve the problems of long process route, low product yield and selectivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) 5%CuO-0.6%PdO-0.06%Ag 2 O / 90%Al 2 o 3 -10% ReO 3 Catalyst preparation

[0057] To 90gγ-Al 2 o 3 and 10g ReO 3 Add 3g of citric acid, 1.2g of methyl cellulose and 2g of scallop powder, mix evenly, adopt equal volume impregnation method, add 15.2g of Cu(NO 3 ) 2 ·3H 2 O, 1.13g Pd(NO 3 ) 2 2H 2 O and 0.09gAgNO 3 100ml of aqueous solution, after the adsorption balance, knead it into a plastic block, then extrude the block into a clover shape with an extruder, dry at 130°C for 6h, and roast at 400°C for 5h to obtain the catalyst 5% CuO -0.6%PdO-0.06%Ag 2 O / 90%Al 2 o 3 -10% ReO 3 .

[0058] (2) 2% Ru 2 o 3 -1%SnO 2 -0.3%Nb 2 o 5 / 78%Al 2 o 3 -22% Mg 2 Preparation of Si catalyst

[0059] to 78gγ-Al 2 o 3 and 22g Mg 2 Add 4g of citric acid, 1g of methyl cellulose and 1.5g of scallop powder to Si, and after mixing evenly, use equal volume impregnation method, add 9.5g of N 4 o 10 Ru, 2.7g Sn(NO 3 ) 4 and 0.9g Nb(NO 3 ) 5 100ml of aqueous so...

Embodiment 2

[0101] (1) 3%CuO-0.4%PdO-0.04%Ag 2 O / 88%Al 2 o 3 -12% ReO 3 Catalyst preparation

[0102] to 88gγ-Al 2 o 3 and 12g ReO 3 Add 2g of citric acid, 1g of methyl cellulose and 1.5g of scallop powder, mix evenly, use equal volume impregnation method, add 9.1g of Cu(NO 3 ) 2 ·3H 2 O, 0.75g Pd(NO 3 ) 2 2H 2 O and 0.06gAgNO 3 In 100ml aqueous solution, after the adsorption balance, knead it into a plastic block, then extrude the block into a clover shape with an extruder, dry at 120°C for 4h, and roast at 350°C for 7h to obtain the catalyst 3% CuO -0.4%PdO-0.04%Ag 2 O / 88%Al 2 o 3 -12% ReO 3 .

[0103] (2) 1% Ru 2 o 3 -0.5%SnO 2 -0.1% Nb 2 o 5 / 75%Al 2 o 3 -25% Mg 2 Preparation of Si catalyst

[0104] to 75gγ-Al 2 o 3 and 25g Mg 2 Add 3g of citric acid, 1.5g of methylcellulose and 2.0g of turnip powder to Si, mix well, and use equal volume impregnation method, add 4.8g of N 4 o 10 Ru, 1.4g Sn(NO 3 ) 4 and 0.3g Nb(NO 3 ) 5 100ml of aqueous solution, aft...

Embodiment 3

[0110] (1) 7%CuO-0.8%PdO-0.08%Ag 2 O / 92%Al 2 o 3 -8%ReO 3 Catalyst preparation

[0111] To 92gγ-Al 2 o 3 and 8g ReO3 Add 4g of citric acid, 1.5g of methyl cellulose and 2.5g of scallop powder, after mixing evenly, use equal volume impregnation method, add 21.3g of Cu(NO 3 ) 2 ·3H 2 O, 1.51g Pd(NO 3 ) 2 2H 2 O and 0.12gAgNO 3 100ml of aqueous solution, after the adsorption balance, knead it into a plastic block, then extrude the block into a clover shape with an extruder, dry at 140°C for 8h, and roast at 450°C for 3h to obtain the catalyst 7% CuO -0.8%PdO-0.08%Ag 2 O / 92%Al 2 o 3 -8%ReO 3 .

[0112] (2) 3% Ru 2 o 3 -1.5%SnO 2 -0.5% Nb 2 o 5 / 80%Al 2 o 3 -20% Mg 2 Preparation of Si catalyst

[0113] to 80gγ-Al 2 o 3 and 20g Mg 2 Add 2g of citric acid, 2g of methyl cellulose and 2.5g of scallop powder to Si, mix evenly, adopt equal volume impregnation method, add 14.3g of N 4 o 10 Ru, 4.1g Sn(NO 3 ) 4 and 1.5g Nb(NO 3 ) 5 100ml of aqueous solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com