Self-cleaning treatment method for electric boiler steel plate

A treatment method and electric heating boiler technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of reduced thermal conductivity of electric heating boiler steel plates, adhesion to the inner wall of electric heating boilers, threats to user life safety, etc., to ensure human safety Healthy, enhanced anti-atmospheric and superheated steam corrosion ability, avoid the effect of uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

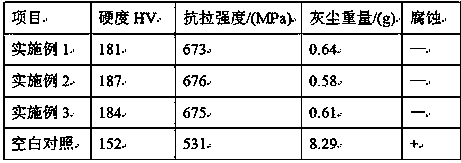

Embodiment 1

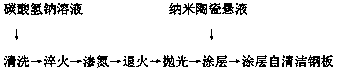

[0024] A self-cleaning treatment method for an electric boiler steel plate, comprising the following steps:

[0025] (1) Cleaning: Place the electric heating steel plate in a sodium bicarbonate solution with a mass percent concentration of 4%, a temperature of 50°C, and ultrasonically clean it for 40 minutes, then rinse it with clean water to fully remove the stains on the surface of the steel plate and keep the steel plate clean , which is convenient for post-processing, drying, and cleaning of the steel plate;

[0026] (2) Quenching: Put the cleaned steel plate in a vacuum furnace, heat it to 570°C at a rate of 4°C / min, keep it for 60 minutes, then continue to heat it to 1040°C, and keep it at 90°C, so that the steel plate can be fully heated and the internal and external temperatures are consistent. Make the steel plate fully austenitized, take it out, put it in the quenching liquid, the temperature of the quenching liquid is 2~10°C, the preparation method of the quenching ...

Embodiment 2

[0032] A self-cleaning treatment method for an electric boiler steel plate, comprising the following steps:

[0033] (1) Cleaning: Place the electric heating steel plate in a sodium bicarbonate solution with a mass percentage concentration of 4.5%, a temperature of 53°C, ultrasonic cleaning for 45 minutes, and then rinse with clean water to fully remove the stains on the surface of the steel plate and keep the steel plate clean , which is convenient for post-processing, drying, and cleaning of the steel plate;

[0034] (2) Quenching: Put the cleaned steel plate in a vacuum furnace, heat it to 590°C at a rate of 4.5°C / min, keep it for 70 minutes, then continue to heat it to 1060°C, and keep it at 105°C, so that the steel plate can be fully heated and the internal and external temperatures are consistent. Make the steel plate fully austenitized, take it out, put it in the quenching liquid, the temperature of the quenching liquid is 2~10°C, the preparation method of the quenching...

Embodiment 3

[0040] A self-cleaning treatment method for an electric boiler steel plate, comprising the following steps:

[0041] (1) Cleaning: Place the electric heating steel plate in a sodium bicarbonate solution with a mass percent concentration of 5%, a temperature of 55°C, ultrasonic cleaning for 50 minutes, and then rinse with clean water to fully remove stains on the surface of the steel plate and keep the steel plate clean , which is convenient for post-processing, drying, and cleaning of the steel plate;

[0042] (2) Quenching: Put the cleaned steel plate in a vacuum furnace, heat it to 610°C at a rate of 5°C / min, keep it for 80 minutes, then continue to heat it to 1080°C, and keep it at 120°C, so that the steel plate can be fully heated, and the internal and external temperatures are consistent. Make the steel plate fully austenitized, take it out, put it in the quenching liquid, the temperature of the quenching liquid is 2~10°C, the preparation method of the quenching liquid is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com